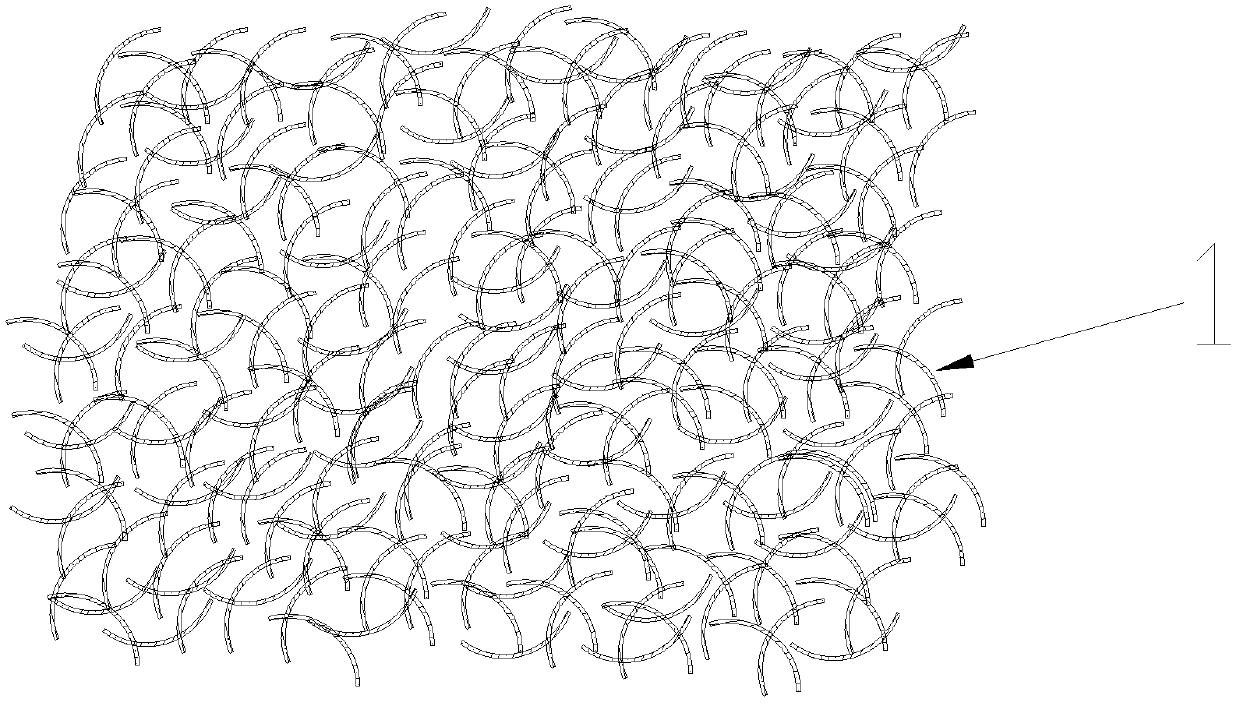

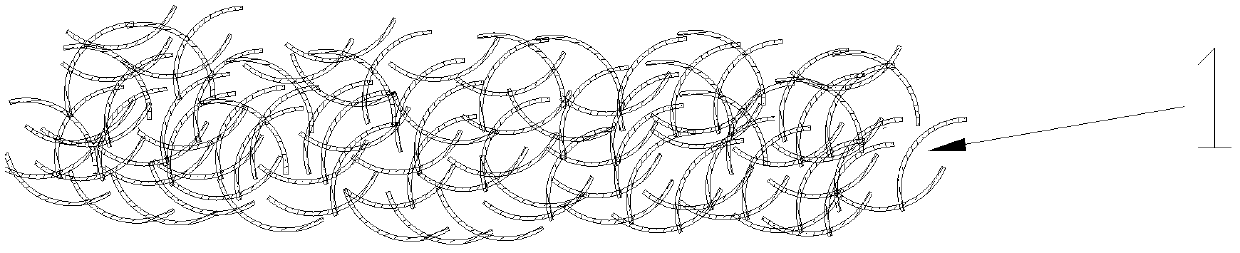

Fiber mat, preparation method and core material for vacuum thermal insulation plate

A fiber mat and glass fiber technology, which is applied in the field of new fiber mats, can solve the problems of disordered fiber structure, difficulty in obtaining lower thermal conductivity, and wide fiber size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

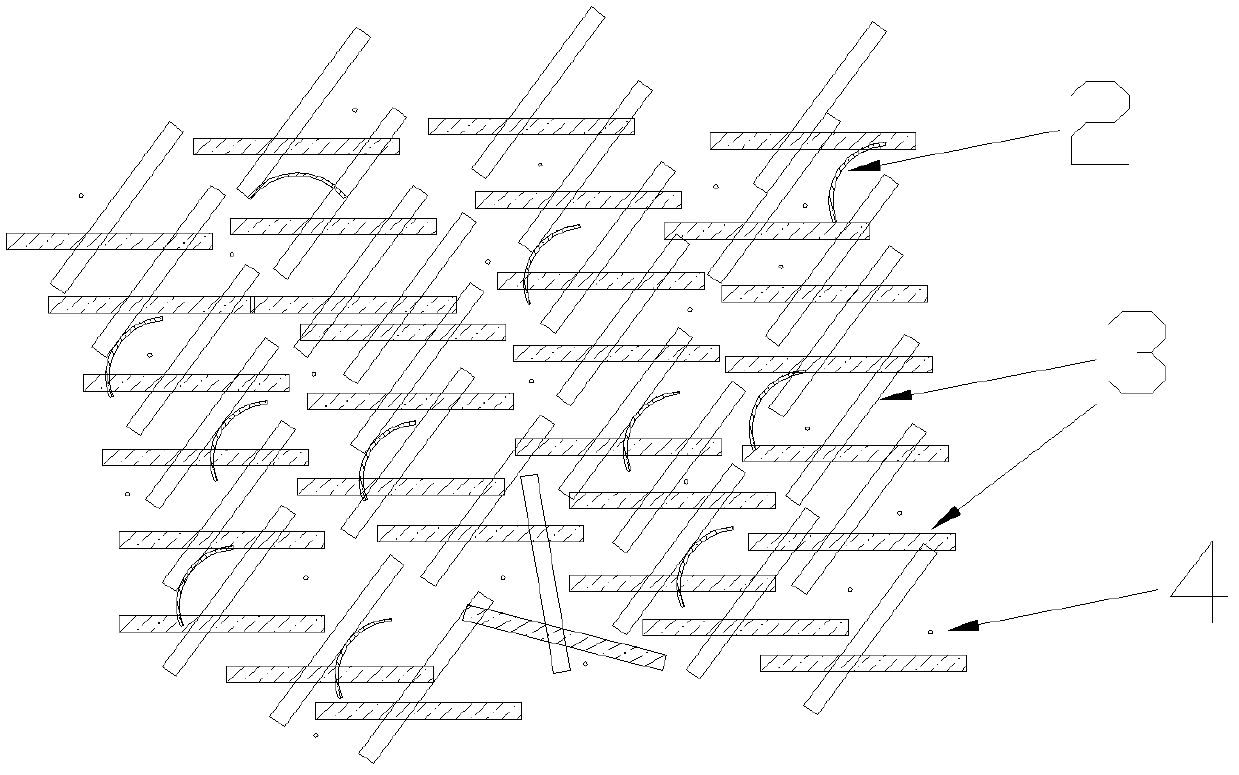

[0062] Fiber felt of the present invention, its needle punching preparation process is as follows:

[0063] (1) 25Kg of glass fiber chopped strands (preferred length 75mm, fiber diameter 9μm), 3Kg of glass microfibers (average diameter not greater than 6 microns) and 280g of carbon black are weighed and batched, and put into a rough opener for Coarse opening, enter the fine opening machine through the cotton mixing box for fine opening, and then fully mix through the vibrating cotton box, etc., and send it to the carding machine for complete opening, uniform carding and distribution of fiber filaments;

[0064] (2) Afterwards, it is transferred to the net-laying machine for net-laying;

[0065] (3) Feed the laid out fiber web into the pre-needling machine and the main needling machine for needling and shaping. The needling density is 8-12 needles / cm2 to obtain the required fiber mat with a thickness of 5mm.

Embodiment 2

[0067] Fiber felt of the present invention, its needle punching preparation process is as follows:

[0068] (1) 50Kg of glass fiber chopped strands (preferred length 50mm, fiber diameter 13μm), glass microfibers (average diameter not greater than 6 microns) 5Kg and polyester fiber (1.8tex, 38mm) 1Kg after weighing and batching, Put it into the rough opener for rough opening, enter the fine opener through the mixing box for fine opening, and then fully mix through the vibrating cotton box, etc., and then send it to the carding machine for complete opening, uniform carding, and distribution of fiber filaments. ;

[0069] (2) Afterwards, it is transferred to the net-laying machine for net-laying;

[0070] (3) Feed the laid out fiber web into the spunlace unit for high-pressure nozzle spunlace setting, the spunlace pressure is 10-20bar

[0071] (4) Transport the wet fiber mat to an oven for drying, take it out to obtain the required fiber mat, and its thickness is 10mm.

Embodiment 3

[0073] Fiber felt of the present invention, its needle punching preparation process is as follows:

[0074] (1) 50Kg of glass fiber chopped strands (preferably 65mm in length, 18μm in fiber diameter), 5Kg of rock wool (average diameter not greater than 4 microns) and 0.5Kg of polypropylene fiber (1.2tex, 70mm) are weighed and batched, Put it into the rough opener for rough opening, enter the fine opener through the mixing box for fine opening, and then fully mix through the vibrating cotton box, etc., and then send it to the carding machine for complete opening, uniform carding, and distribution of fiber filaments. ;

[0075] (2) Afterwards, it is transferred to the net-laying machine for net-laying;

[0076] (3) Feed the laid out fiber web into the hot rolling unit for heating (150-200°C) and pressure (5-10Kg / cm2) hot rolling, the fiber web is fixed, and the required fiber mat is obtained after taking it out. The thickness is 7mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com