High-strength, flame-proof vacuum insulation plate and manufacture method thereof

A vacuum insulation panel, high-strength technology, applied in heat exchange equipment, mechanical equipment, pipeline protection through heat insulation, etc., can solve the problems of poor impact resistance, low strength of vacuum insulation panels, high temperature resistance and unsatisfactory flame retardancy, etc. problem, to achieve the effect of reducing the heat conduction area, good impact resistance, and strong flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

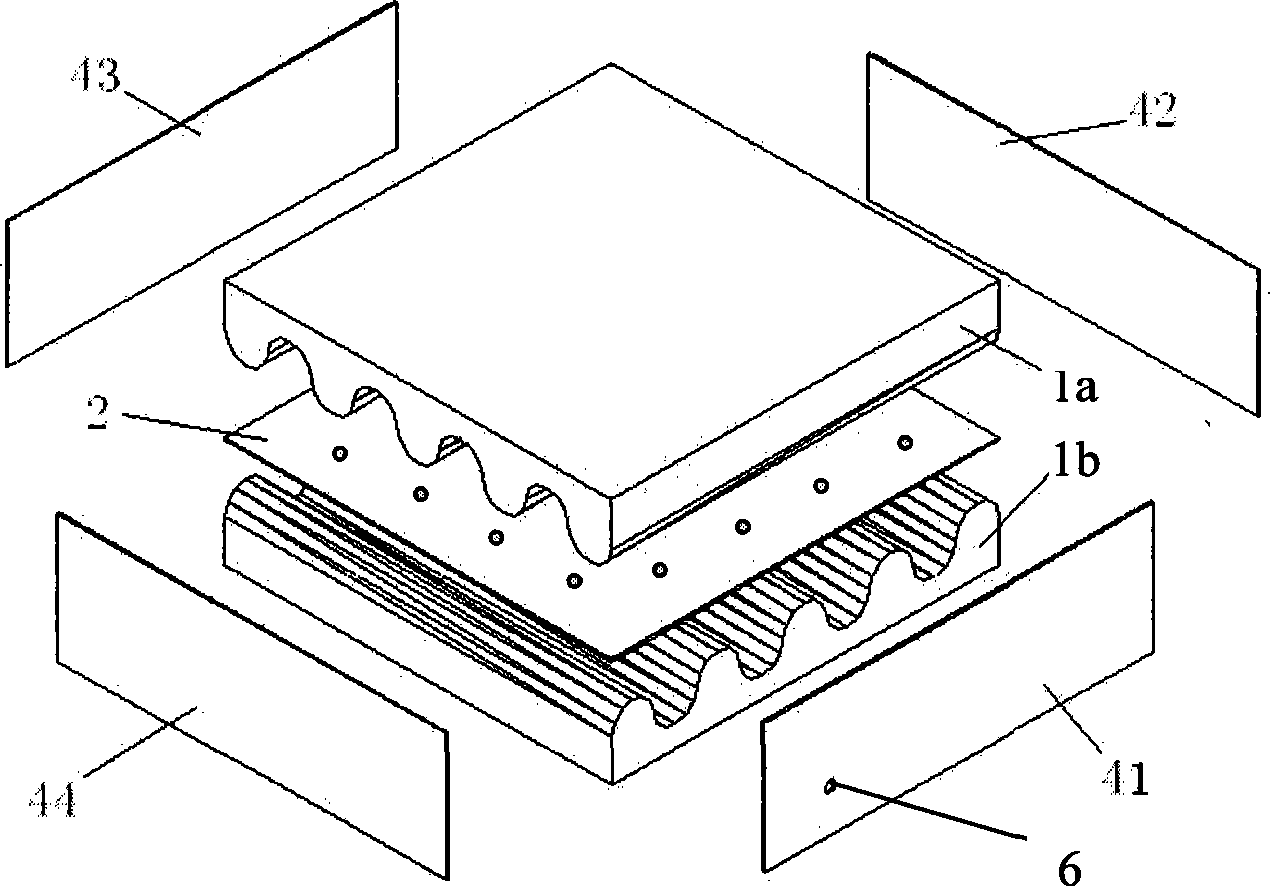

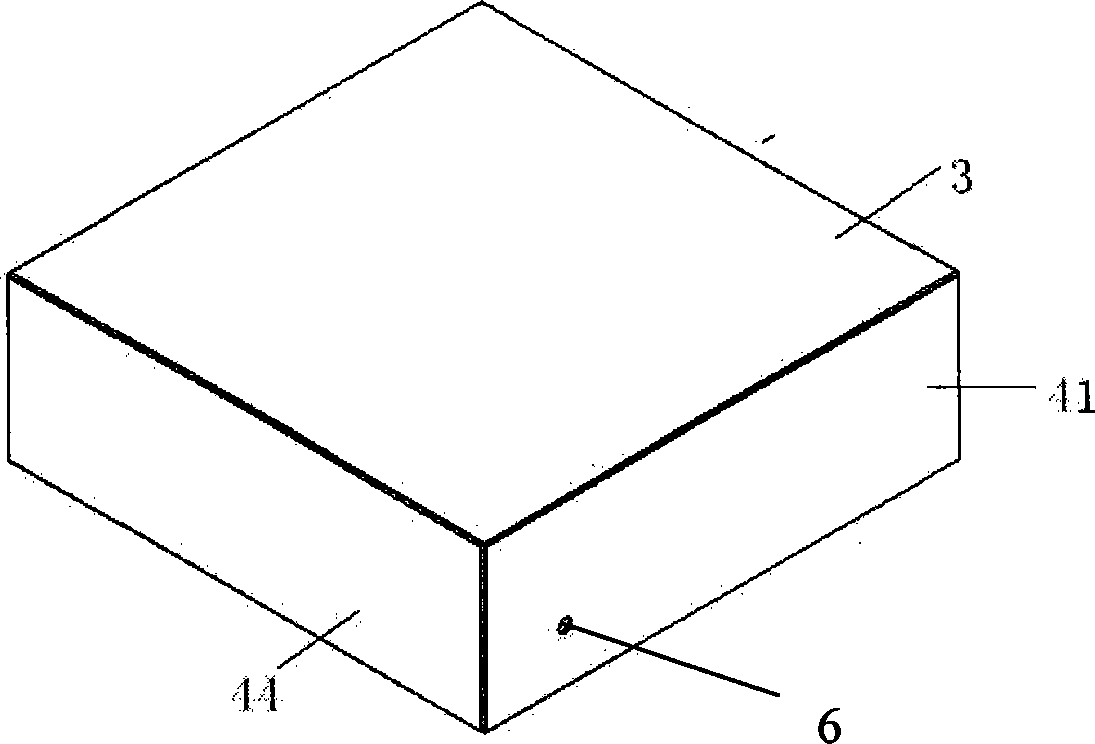

[0040] Referring to the accompanying drawings, the high-strength, flame-retardant vacuum insulation panel of the present invention includes a core material and a sealing film wrapped outside the core material. The core material includes an intermediate layer 2, and an insulating material layer 1a is stacked on the upper and lower sides of the intermediate layer 2, respectively. and the heat insulating material layer 1b, the middle layer 2 is a double-sided aluminum film of fiber paper, the side of the heat insulating material layer 1a and the heat insulating material layer 1b facing the middle layer 2 is a corrugated surface, and the corrugated depressions of the corrugated surface are filled with carbon dioxide Silica airgel and getter, the side of the heat insulating material layer 1a and the heat insulating material layer 1b facing away from the middle layer 2 is a plane, and this plane is adhered with a reflective layer, for example, the plane side of the heat insulating mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com