Abrasion resistant material featuring ceramic embedded in metal and preparation method thereof

A technology of wear-resistant materials and ceramics, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of short life, being subjected to alternating impact loads, aging of adhesives, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Adhesive method to prepare wear-resistant materials embedded with ceramics in metal:

[0035] 1) First prepare the adhesive according to the composition of the following parts by weight: 100 parts of epoxy resin, 20 parts of dibutyl phthalate, 100 parts of alumina powder (300 mesh), 8 parts of ethylenediamine (epoxy resin The preferred grade is E-51 or E-44);

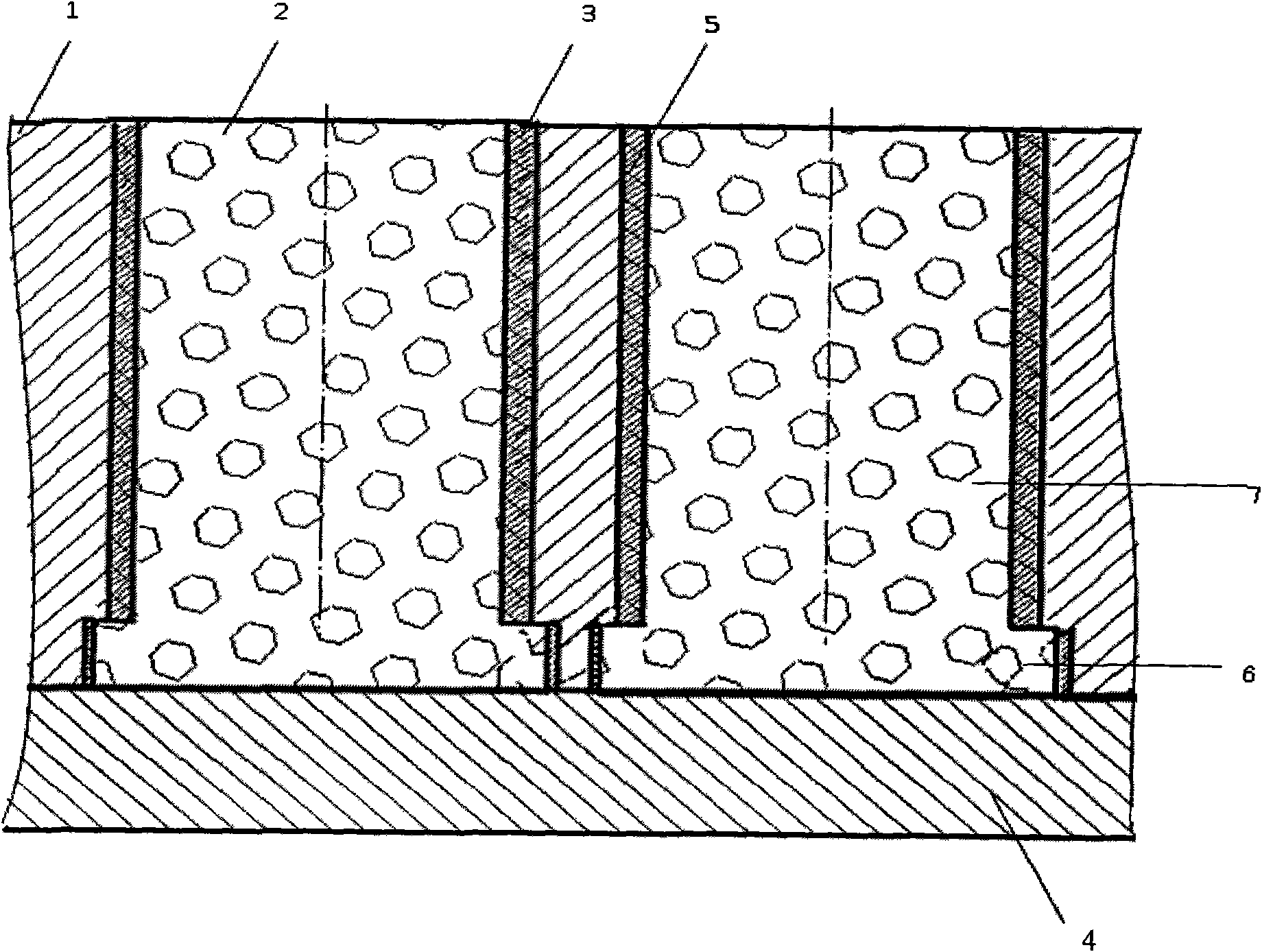

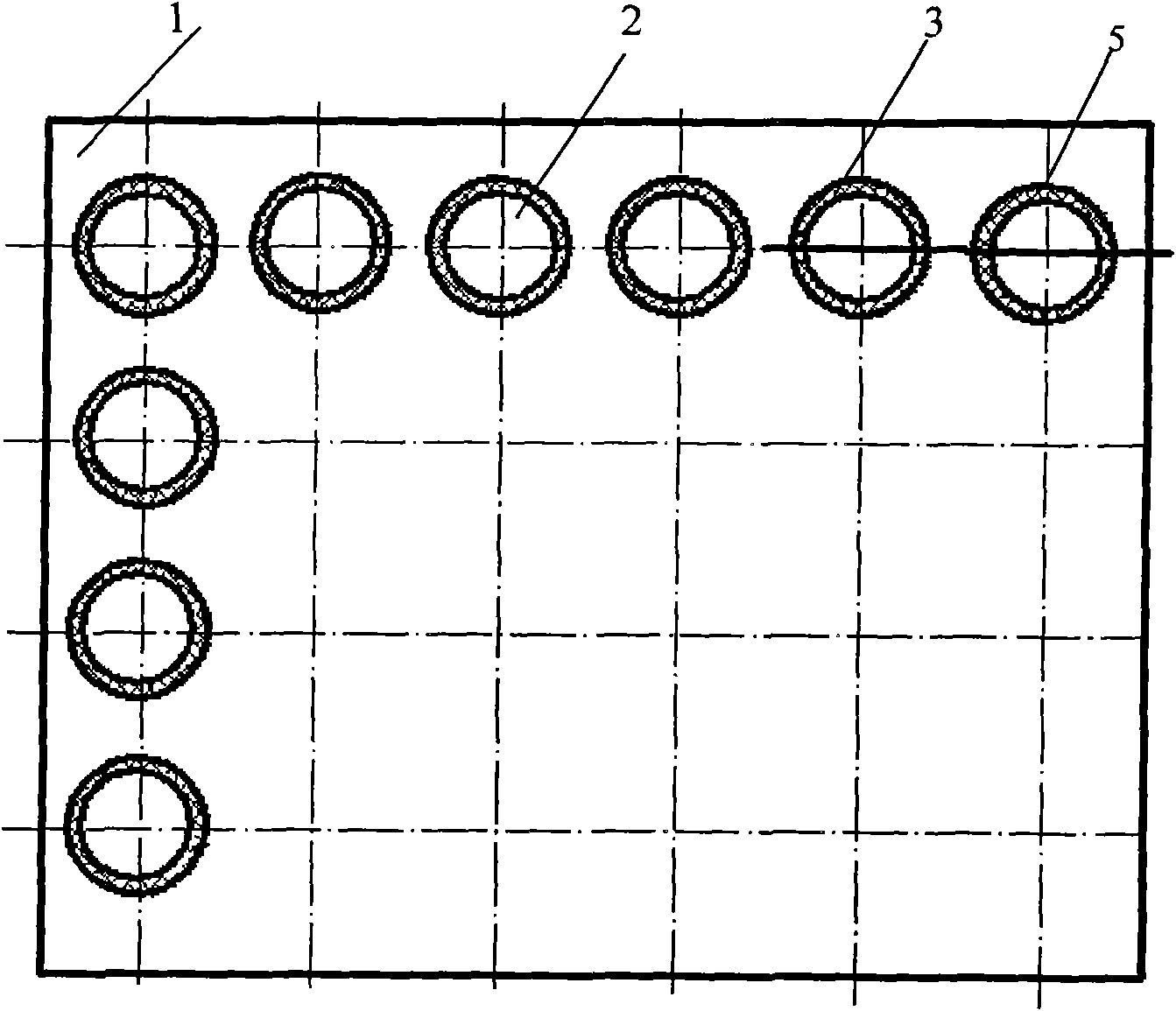

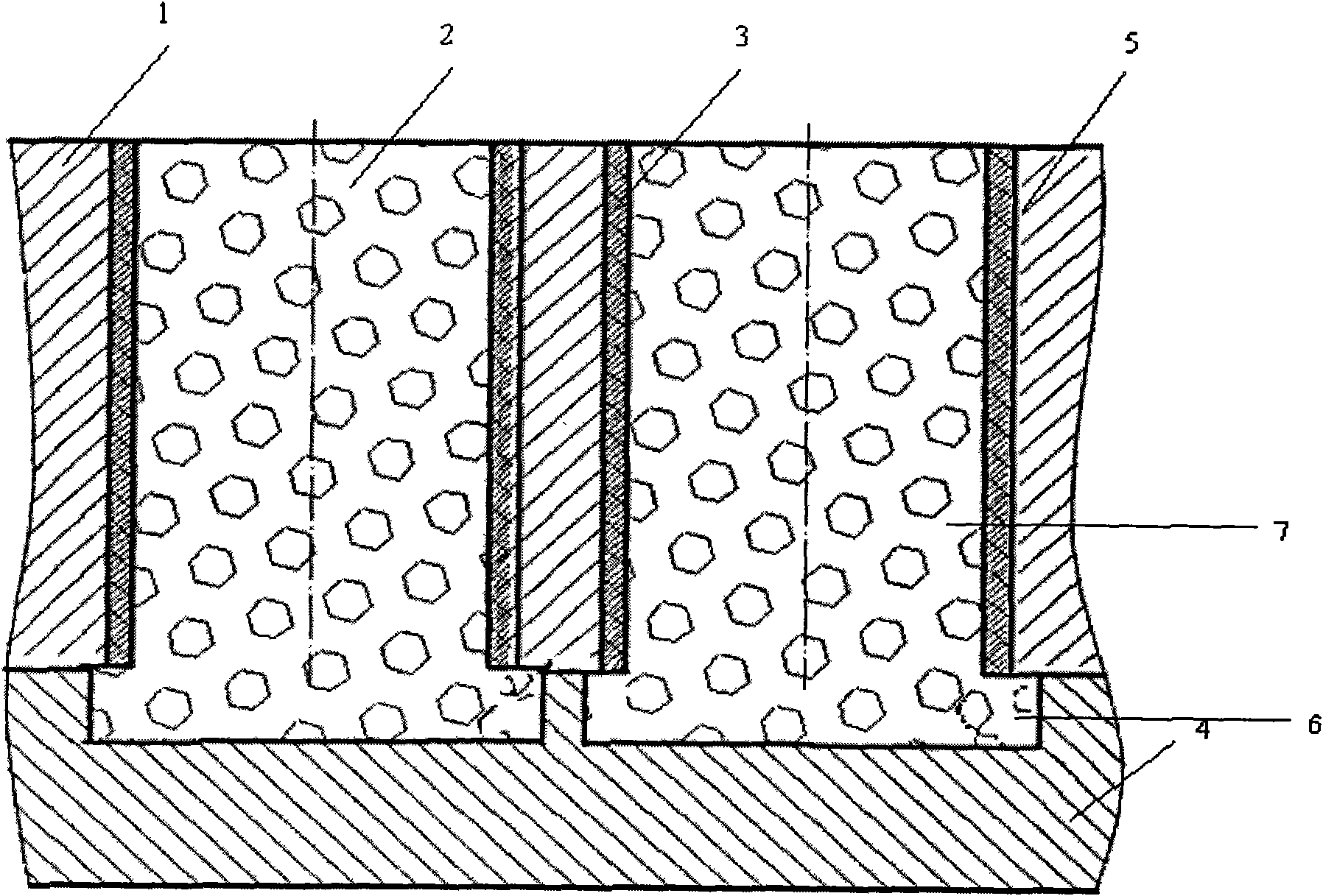

[0036] 2) Apply the adhesive evenly on the surface of the wear-resistant ceramic block, the thickness of the coating is 1.8-2.5mm, and then install the wear-resistant ceramic block in the through hole of the substrate, and make the gap between the through hole and the wear-resistant ceramic block Evenly, after the adhesive is cured, the excess adhesive at the gap between the upper and lower surfaces shall be polished clean (the wear-resistant ceramic block is an alumina ceramic block produced by the existing technology, and the wear-resistant ceramic block is a combination of coaxial cylinders. The diameter of t...

Embodiment 2

[0039] Adhesive method to prepare wear-resistant materials embedded with ceramics in metal:

[0040] 1) First prepare the adhesive according to the following parts by weight: 100 parts of epoxy resin, 20 parts of dibutyl phthalate, 80 parts of alumina powder (300 mesh), 20 parts of silicon powder (300 mesh), 8 parts of diethylenetriamine (the preferred grade of epoxy resin is E-51 or E-44);

[0041] 2) Apply the adhesive evenly in the through hole of the substrate, the thickness of the coating is 1.5-2.0mm, and then install the wear-resistant ceramic block in the through hole of the substrate, and make the gap between the through hole and the wear-resistant ceramic block Evenly, after the adhesive is cured, the excess adhesive at the gap between the upper and lower surfaces shall be polished clean (the wear-resistant ceramic block is an alumina ceramic block produced by the existing technology, and the wear-resistant ceramic block is a combination of coaxial cylinders. The di...

Embodiment 3

[0044] Preparation of wear-resistant materials inlaid with ceramics in metals by hot charging:

[0045] 1) Heat the substrate with through holes to 120°C in the furnace. After the diameter of the through hole on the substrate becomes larger due to expansion, immediately install the wear-resistant ceramic block into the through hole. After cooling, the through hole shrinks, and the wear-resistant The ceramic block is firmly fixed in the through hole (the wear-resistant ceramic block is an alumina ceramic block produced by the prior art, the wear-resistant ceramic block is a combination of coaxial cylinders, the diameter of the working section is 8mm, the height is 8mm, The diameter of the positioning section is 10mm and the height is 3mm; 8mm thick low-carbon steel is selected as the substrate 1, the length and width of the substrate 1 are 166mm and 86mm respectively, and 10×5 through holes with a diameter of 7.9mm are opened on the substrate 1 , the through holes are evenly di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com