Titanium steel composite slab and manufacturing method thereof

A composite plate and manufacturing method technology, applied in the field of titanium steel composite plate, can solve the problems that it is difficult to realize the manufacture of small-sized titanium steel composite plate, affect the weather resistance performance of the composite plate, affect the structural performance, etc., and achieve enhanced atmospheric corrosion resistance and low cost. Low, good structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

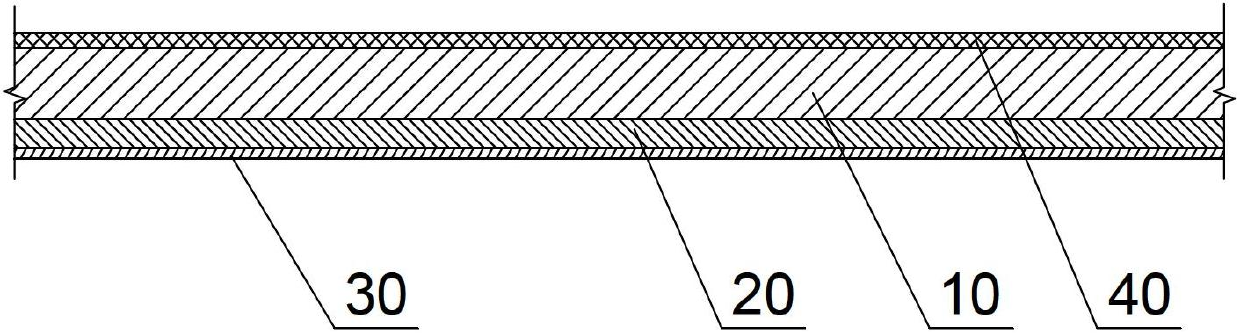

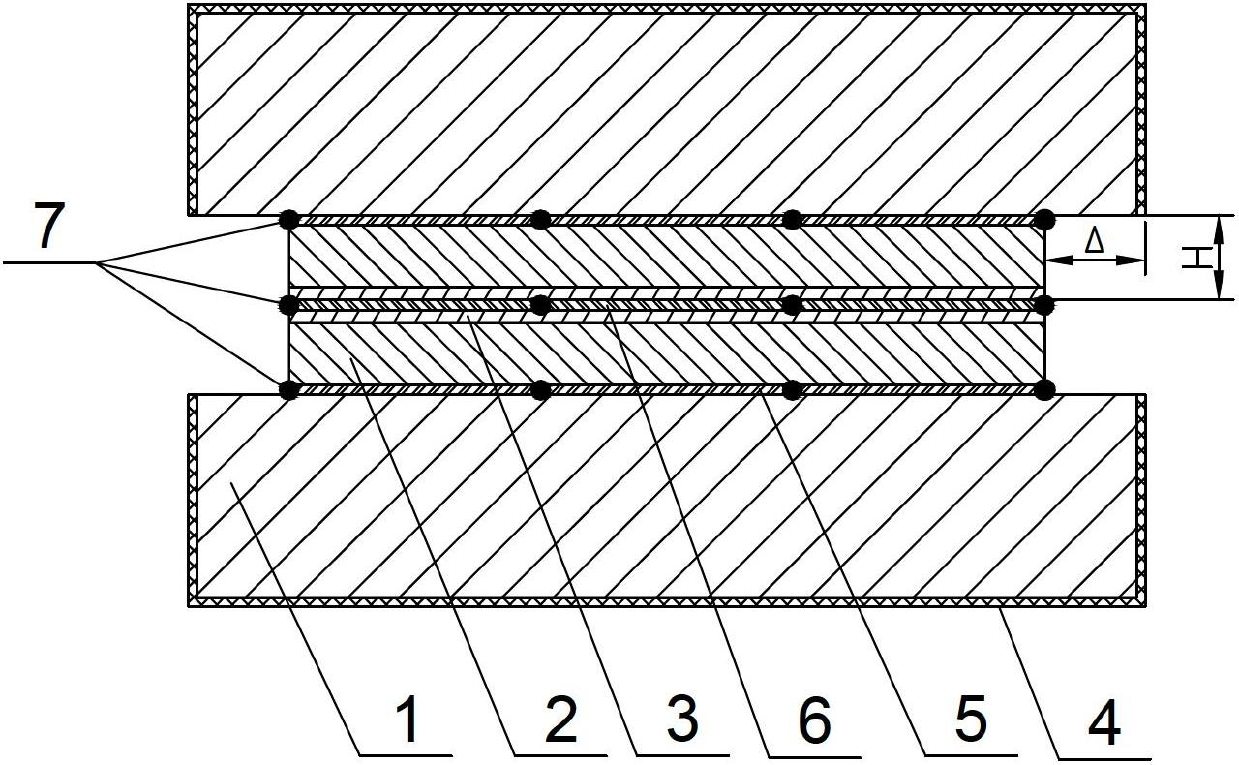

[0045] like figure 1 , figure 2 As shown, the titanium-steel composite plate in this embodiment is a double-layer composite plate, and its cross-sectional structure includes a weather-resistant steel bottom layer 10 and a titanium composite layer 20, and the titanium composite layer 20 is compounded on the weather-resistant steel bottom layer 10. One plate surface is one surface, the exposed surface of the titanium composite layer 20 is a titanium oxide layer 30, the surface of the titanium oxide layer 30 is transparent, and it is decorative for building materials. The weather-resistant steel bottom plate layer The exposed surface of 10 is an oxide layer 40 of steel, which can be bluish or blackened, so that the weather resistance of the oxide layer is stronger, and the weather resistance of the entire plate is more stable. The titanium composite layer 20 and the weather-resistant steel bottom layer 10 are composited into one through a hot rolling process, and the composite ...

Embodiment 2

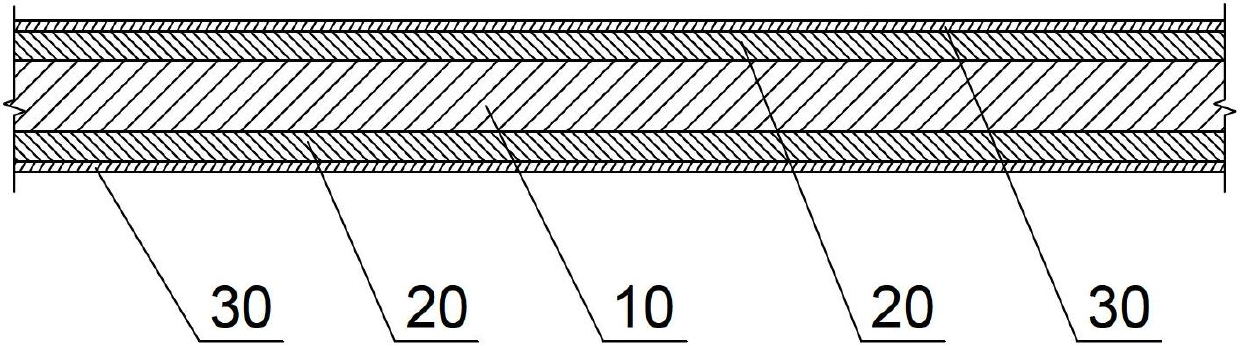

[0057] like image 3 , Figure 4 As shown, the titanium-steel composite plate in this embodiment is a three-layer composite plate, and its cross-sectional structure includes a weather-resistant steel bottom layer 10 and a titanium composite layer 20, and the titanium composite layer 20 is compounded on the weather-resistant steel bottom layer 10. The two board surfaces are both sides, the exposed surface of the titanium composite layer 20 is a titanium oxide layer 30, and the titanium composite layer 20 and the weather-resistant steel base layer 10 are composited into one body through a hot rolling process, so The composite interface between the titanium composite layer 20 and the weather-resistant steel bottom plate layer 10 is a metal bonding, and the thickness of the titanium-steel composite plate is 5.5mm, wherein the thickness of each titanium composite layer 20 is 0.2mm, The thickness range of the titanium-steel composite plate may be 0.5-5.5 mm, wherein the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com