Method for preparing 300MPa grade and isotropous AZ31 magnesium alloy sheet

An isotropic, magnesium alloy technology, applied in the direction of sheet/plate, temperature control, building components, etc., can solve problems such as difficult to meet performance requirements, uneconomical, etc., achieve low production cost, less one-time investment, and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

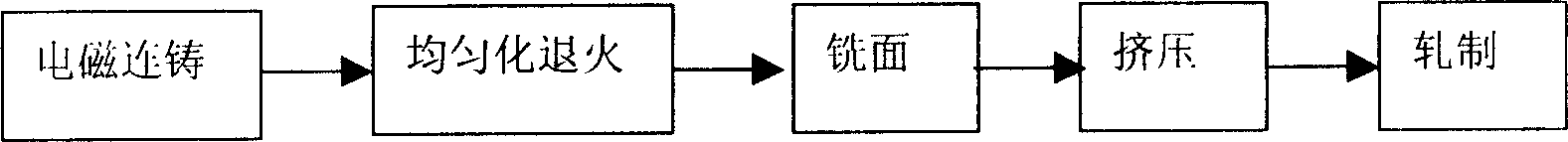

[0020] AZ31 magnesium alloy was smelted, purified and electromagnetically continuously cast into an ingot of 165mm. The alloy composition is shown in Table 1. After the ingot is homogenized and annealed at 400℃×18 hours, the surface is milled and extruded into strips at 300℃. The extrusion ratio is 15, the extrusion (exit) speed is 20m / min, and the thickness of the extruded sheet is 7mm. . Then cut the extruded sheet into sheets with a width of 330mm along the extrusion direction, heat the sheet to 300°C, preheat the rolls of the rolling mill to 150°C, and start rolling, the slab is rolled perpendicular to the original extrusion direction, rolling The speed is 12 m / min; the first pass can reach 40%, the second pass can reach 25%, and the third pass can reach 12%, in order to ensure the flatness of the plate and the dimensional accuracy, close to the product size In the last 1 to 3 passes, the pass reduction should be 4%. After 3 passes of rolling, return to the furnace for ...

Embodiment 2

[0023] AZ31 magnesium alloy was smelted, purified and electromagnetically continuously cast into an ingot of 165mm. The alloy composition is shown in Table 1. After the ingot is homogenized and annealed at 350℃×20 hours, the surface is milled and extruded into strip at 300℃. The extrusion ratio is 8, the extrusion (exit) speed is 30m / min, and the width of the strip after extrusion The thickness is 20mm. Then cut the extruded sheet into a sheet 10mm wider than the finished sheet width along the extrusion direction, heat the sheet to 400°C, preheat the rolls of the rolling mill to 100°C, and start rolling, the slab is rolled perpendicular to the original extrusion direction The rolling speed is 15 m / min; the first pass can reach 50%, the second pass can reach 30%, and the third pass can reach 15%, in order to ensure the flatness and dimensional accuracy of the plate , When approaching the last 1 to 3 passes of the product size, the pass reduction should be about 5%. After 3 p...

Embodiment 3

[0025] AZ31 magnesium alloy was smelted, purified and electromagnetically continuously cast into an ingot of 165mm. The alloy composition is shown in Table 1. After the ingot is homogenized and annealed at 380℃×15 hours, the surface is milled and extruded into strip at 400℃. The extrusion ratio is 8, the extrusion (exit) speed is 10m / min, and the thickness of the strip after extrusion is 15mm. Then cut the extruded sheet into a sheet 20mm wider than the finished sheet width along the extrusion direction, heat the sheet to 300°C, preheat the rolls of the rolling mill to 120°C, and start rolling, the slab is rolled perpendicular to the original extrusion direction The rolling speed is 10 m / min; the first pass can reach 30%, the second pass can reach 20%, and the third pass can reach 10%. In order to ensure the flatness of the plate and the dimensional accuracy , When approaching the last 1 to 3 passes of the product size, the pass reduction should be 3%. After 3 passes of rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com