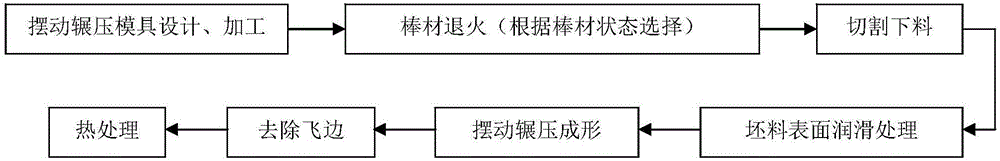

Rotary forging forming method for metal circular plate

A technology of oscillating rolling and forming processing, applied in the direction of sheets/plates, building components, etc., can solve the problems of low production efficiency, low material utilization rate, difficulty in controlling the shape and dimensional accuracy of circular plates, etc., and achieve high production efficiency , high material utilization rate, complete metal streamline effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0032] Specific embodiment 1: select the Ta1 pure tantalum cold-forged bar material of Φ 60mm for use, prepare Φ 150 * 2mm soft state disc, it comprises the following steps:

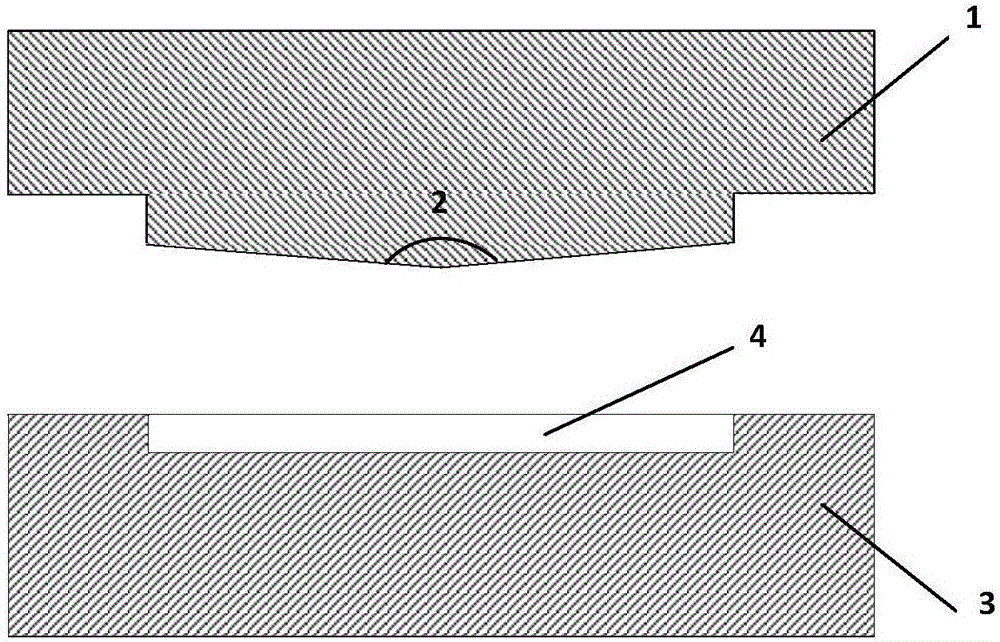

[0033] (1) Design and processing of the circular plate swing rolling mold: the shape of the mold must meet the assembly requirements of the swing rolling machine mold base; the cavity 4 of the lower mold is flat-bottomed and circular, with an inner diameter of 150mm, and the cavity depth of the lower mold is 2mm; the upper mold 1 It is conical, and the taper angle 2 of the upper die is 179°.

[0034] (2) Vacuum anneal the Φ60mm Ta1 bar obtained by cold forging: 1100℃×60min, vacuum degree ≤1.33×10-3Pa.

[0035] (3) Cutting and blanking: Since metal tantalum is more expensive, wire cutting is used for blanking. Blank specification Φ60×12.9mm.

[0036] (4) Billet surface lubrication treatment: Since metal tantalum is easy to stick to the mold, in order to improve the surface quality of the metal circular ...

specific Embodiment 2

[0040] Specific embodiment 2: select the T2 red copper hot-extruded bar of Φ 80mm for use, prepare Φ 200 * 1.5mm hard disc, it comprises the following steps:

[0041] (1) Design and processing of the circular plate swing rolling mold: the shape of the mold must meet the assembly requirements of the swing rolling machine mold base; the cavity of the lower mold is flat-bottomed and circular, with an inner diameter of 200mm and a depth of 1.5mm; the upper mold is conical, with a cone Angle 178 ° .

[0042] (2) Annealing: Copper rods prepared by hot extrusion do not need to be annealed.

[0043] (3) Cutting and blanking: use sawing method for blanking. Blank specification Φ80×9.8mm.

[0044] (4) Billet surface lubrication treatment: Since T2 red copper has good fluidity and is not easy to stick to the mold, it is only necessary to spray ordinary oily lubricant on the surface of the billet.

[0045] (5) Oscillating rolling forming: place the billet at the center of the lower di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com