Composite panels

a technology of composite panels and foam, applied in the field of composite panels, can solve the problems of poor compressive strength of balsa, high cost, environmental concerns, etc., and achieve the effect of improving the bonding strength of honeycomb and foam, reducing the surface area of honeycomb, and reducing the resistance of honeycomb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

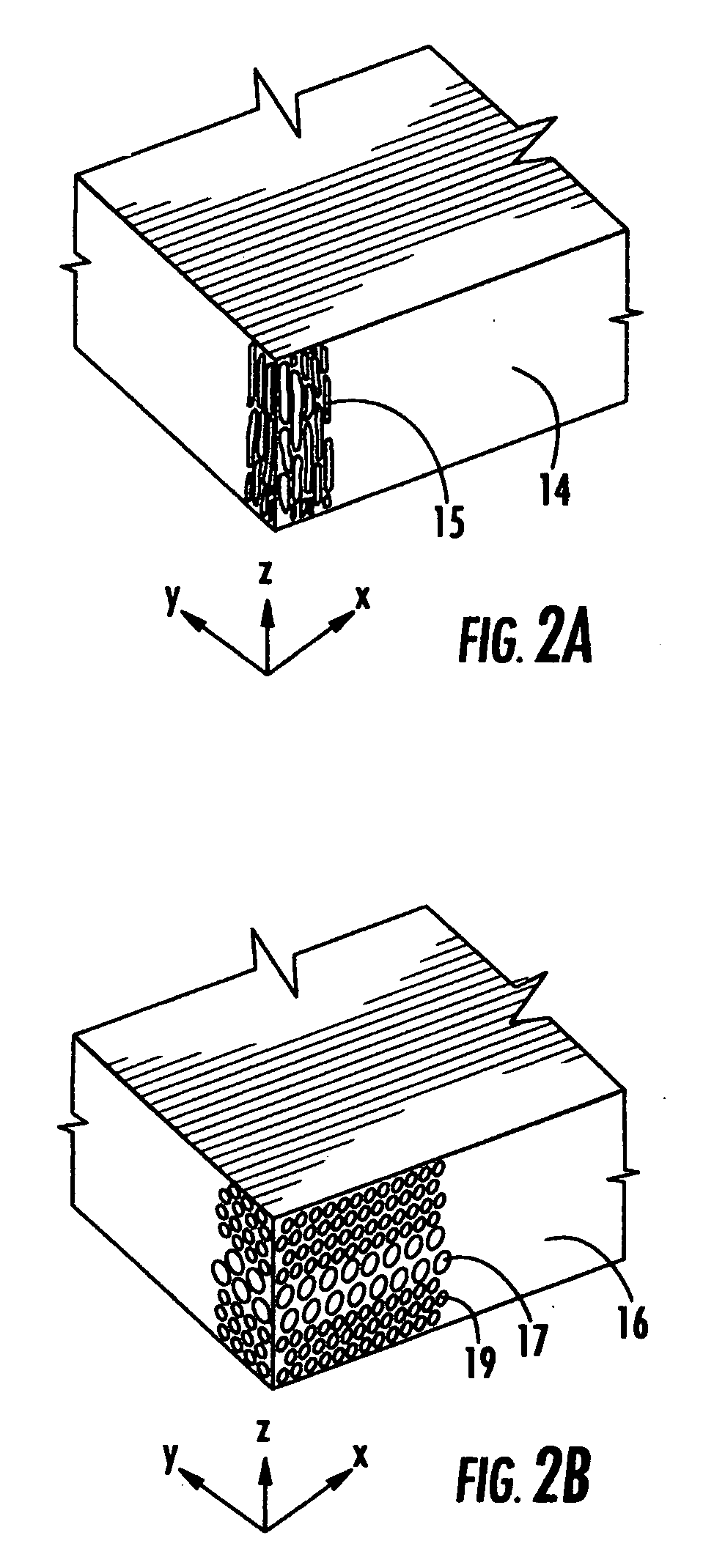

[0023]Referring now to FIG. 2b, therein is shown a core of foamed polymer 16 in which the bubbles which make up the foam are essentially round and vary in size, wherein the bubbles 17 which are close to the center of the core 16 are larger than the bubbles 19 which are closer to the surface of the core 16 (preferably the bubbles are progressively smaller toward the surface of the core 16). As a result the material at the center has a lower density while the material at the surface has a higher density. The higher density of the material at the surface provides greater strength, particularly compressive strength and also provides greater area to bond to the skins.

third embodiment

[0024]Referring now to FIGS. 3a, 3b and 3c, therein is shown the instant invention wherein the core material 20, 22 and 24, respectively, consists of a foamed polymer which contains discrete strands, planes or geometric shapes of more dense or solid thermoplastic material 21, 23 and 25, respectively, which are continuous in the ‘z’ direction as shown. Such geometric shapes may be, for example, discrete rods, and strips or round, square or hexagonal tubes. These more dense or solid regions increase the compressive properties of the foam. The increase in strength and stiffness is out of proportion to the increase in weight because although the solid material of these pillars is thin, it is supported by the foam around it so that it is less likely to buckle when subjected to compressive loads. The more dense or solid material may be the same material (preferably a thermoplastic polymer) as the material of the foam or may be a different but compatible material. The percentage of more de...

fourth embodiment

[0025]Referring now to FIGS. 4a, 4b and 4c, therein is shown the instant invention wherein the geometric shapes of the more solid or dense material in the Z direction 27, 29 and 31, respectively, are connected to form a continuous array in the foamed polymer 26, 28 and 30, respectively. Such connectivity further enhances the compressive strength of the foam as each element may now receive support from adjacent elements when overloaded. The connectivity also increases the shear strength and stiffness of the core structure. Such materials are commercially available from The Dow Chemical Company under the trade name “STRANDFOAM”.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com