Waste oil cloth injection burning environmental protection treatment technology

An environmental protection treatment and oilcloth technology, which is applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of insufficient combustion, black smoke, and waste oilcloth is easy to stick together, so as to ensure economic benefits and social environmental protection benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

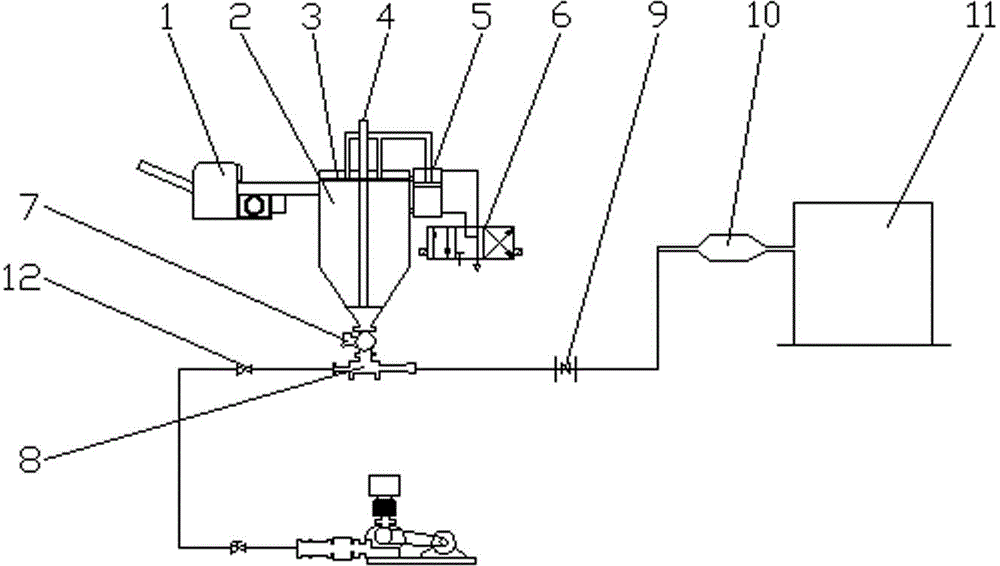

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

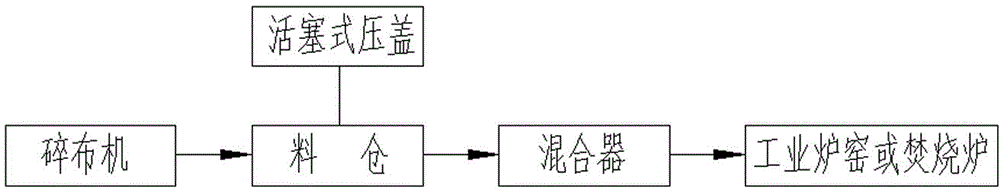

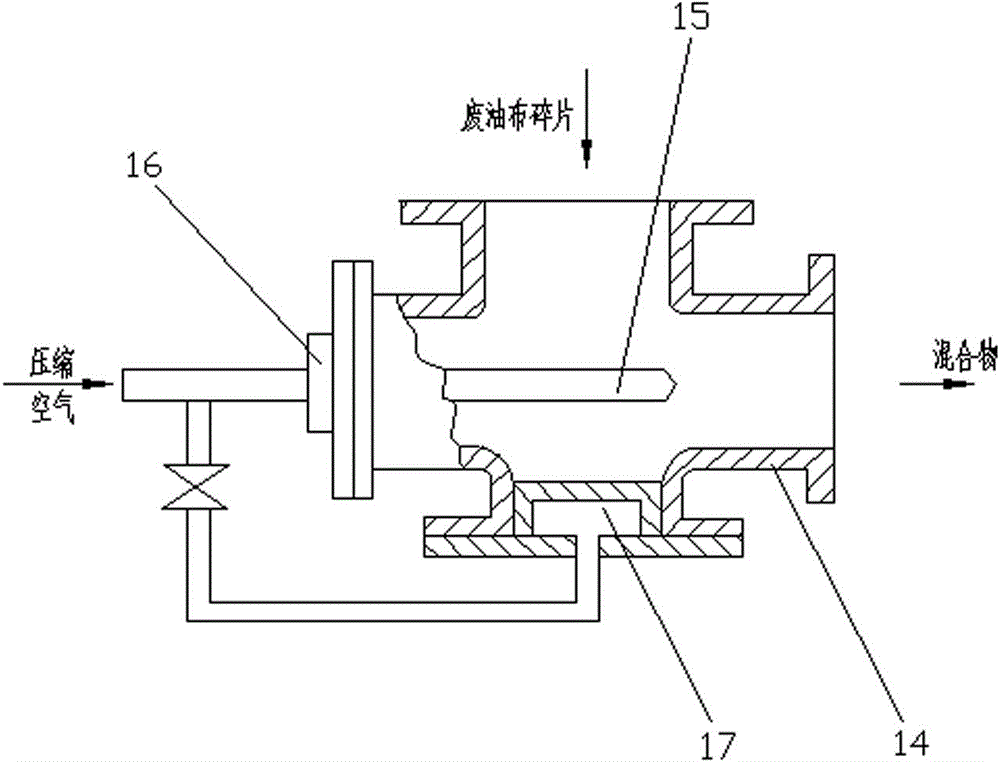

[0021] see Figure 1 ~ Figure 3 ,A sort of Waste tarpaulin injection combustion environmental protection treatment process, the process steps are:

[0022] Step 1: Adopt Rag machine 1 squeezes and shreds the waste tarpaulin. The purpose of extrusion is to squeeze out most of the dirty oil from the waste tarpaulin and collect and recycle it to prevent the fragments from sticking together; the purpose of shredding is to facilitate transportation and blowing;

[0023] Step 2: Cut and squeeze the waste oilcloth Conveying in the silo 2, because the waste tarpaulin fragments are relatively light, they cannot be fed in the silo 2 by their own weight. Therefore, a piston-type gland 3 is installed on the silo 2, and the piston-type gland 3 is driven by the lifting cylinder 5. Through the pre-compression of the piston gland 3, the waste tarpaulin fragment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com