Production method of low-carbon environment-friendly anti-deformation solid wood composite plate

A low-carbon, environmentally friendly and production method technology, which is applied in the joining of wooden veneers, manufacturing tools, and wood processing utensils, etc., can solve the problems of weak wooden doors, easy foaming deformation, abnormal colors, etc. Stable quality and versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

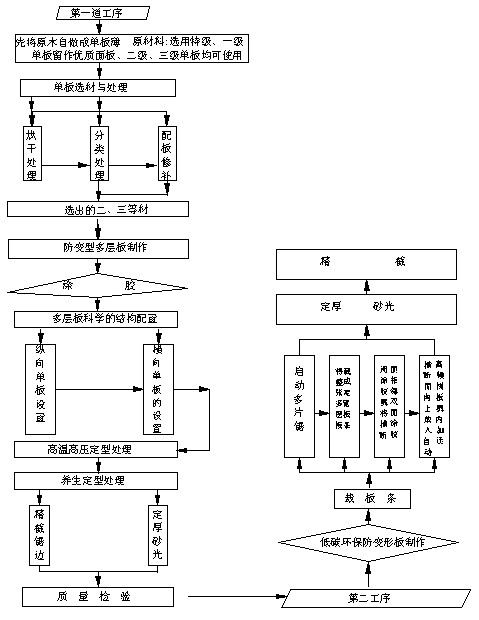

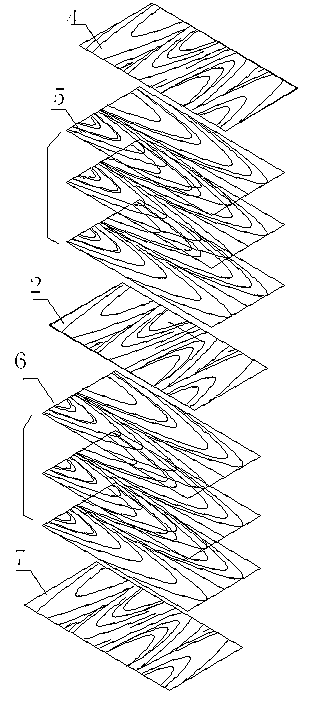

[0042] A method for manufacturing a low-carbon, environment-friendly and anti-deformation solid wood composite board, as shown in the attached figure 1 , attached Figure 6 , attached Figure 7 ,

[0043] attached Figure 9 As shown, it includes the following steps: the first step is to cut the log into 2mm veneers, select the first-grade veneer as the surface layer, select the second-grade veneer as the bottom layer, and select the third-grade veneer as the middle layer board and dried to a moisture content of 6-12%;

[0044] The second step is to use environmentally friendly E0 grade glue with a mass concentration of 70% on the surface where the surface laminate and the middle laminate are in contact.

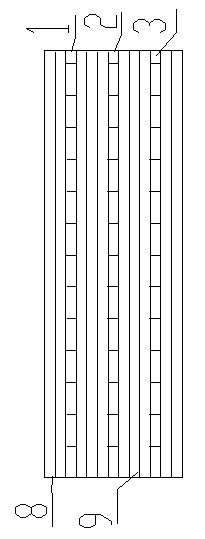

[0045] Apply glue evenly, apply glue on both sides of the middle laminate, press the composite board with a press, and cut the composite board into slats of the same specification;

[0046] The third step is to apply glue on the bottom surface of the surface...

Embodiment 2

[0053] The manufacturing method of the low-carbon environment-friendly anti-deformation solid wood composite board described in this embodiment, the first step is to cut the log into a veneer with a thickness of 2mm on the rotary cutter, select the first-grade veneer as the surface plywood, select The second-level veneer is used as the bottom layer, the third-level veneer is used as the middle layer, the first-level veneer, the second-level veneer, and the third-level veneer are stored in categories, and the moisture content of the veneer is dried by a drum or a vacuum dryer. Dry to 7-11%.

Embodiment 3

[0055] The manufacturing method of the low-carbon environmental protection anti-deformation solid wood composite board described in this embodiment, the second step is to evenly apply glue to the bottom surface of the upper panel, evenly apply glue to the top surface of the lower panel, and evenly apply glue to both sides of the middle layer panel, and the glue is environmentally friendly E0 grade 1. Vegetable glue with zero formaldehyde emission with a glue mass concentration of 65% is pressed into a composite board, and the composite board is cut into slats of the same specification, and the width is made into the thickness of the board according to the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com