Technique for evaporating and recycling wastewater generated in hydroxypropyl methyl cellulose production

A technology for the production of hydroxypropyl methylcellulose and wastewater, which is applied in the fields of chemical instruments and methods, natural water treatment, water/sewage multi-stage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

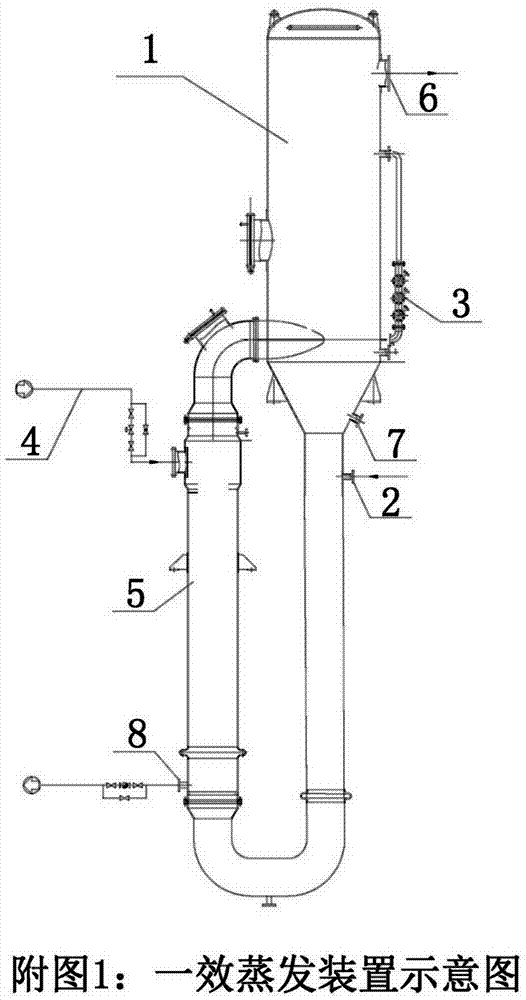

[0012] attached figure 1 A schematic diagram of a one-effect evaporation device of the present invention is shown. Consisting of one-effect evaporator 1, waste water inlet 2, center sight mirror 3, steam inlet 4, first-effect heat exchanger 5, secondary steam outlet 6, waste water outlet 7, condensed water outlet 8, hydroxypropyl methylcellulose production Water enters the first-effect evaporator 1 from the waste water inlet 2, the water level is added to the mirror 3, and the primary steam enters the first-effect heat exchanger 5 from the steam inlet 4 to heat and evaporate the waste water, and the evaporated secondary steam is sent from the secondary steam outlet 6 After entering the second-effect heat exchanger, the primary concentrated waste water enters the second-effect evaporator through the waste water outlet 7, and the primary steam condensed water in the first-effect heat exchanger 5 is recovered to the production system through the condensed water outlet 8.

[0013...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com