Automatic packaging unit for vacuum packaging of inner bag and outer bag

An automatic packaging machine and vacuum packaging technology, applied in the field of material equipment, can solve the problems of easily contaminated materials, high cost, low packaging efficiency, etc., and achieve the effect of improving the degree of automation and production efficiency

Inactive Publication Date: 2010-09-22

李文峰

View PDF6 Cites 45 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition to the metering and vacuum sealing operations, the existing inner and outer bag packaging operations use manual weighing and sub-packaging to set the outer bag. The workload is large, the consistency of the packaged product is poor, the packaging efficiency is low, and the cost is high; Direct contact with materials and packaging bags, easy to pollute materials, does not meet health and safety requirements

At present, there are various styles of automatic packaging vacuum packaging machines on the market, but all automatic vacuum packaging machines are only suitable for single outer bag packaging, and cannot automatically complete the inner and outer bag vacuum packaging of materials at one time.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

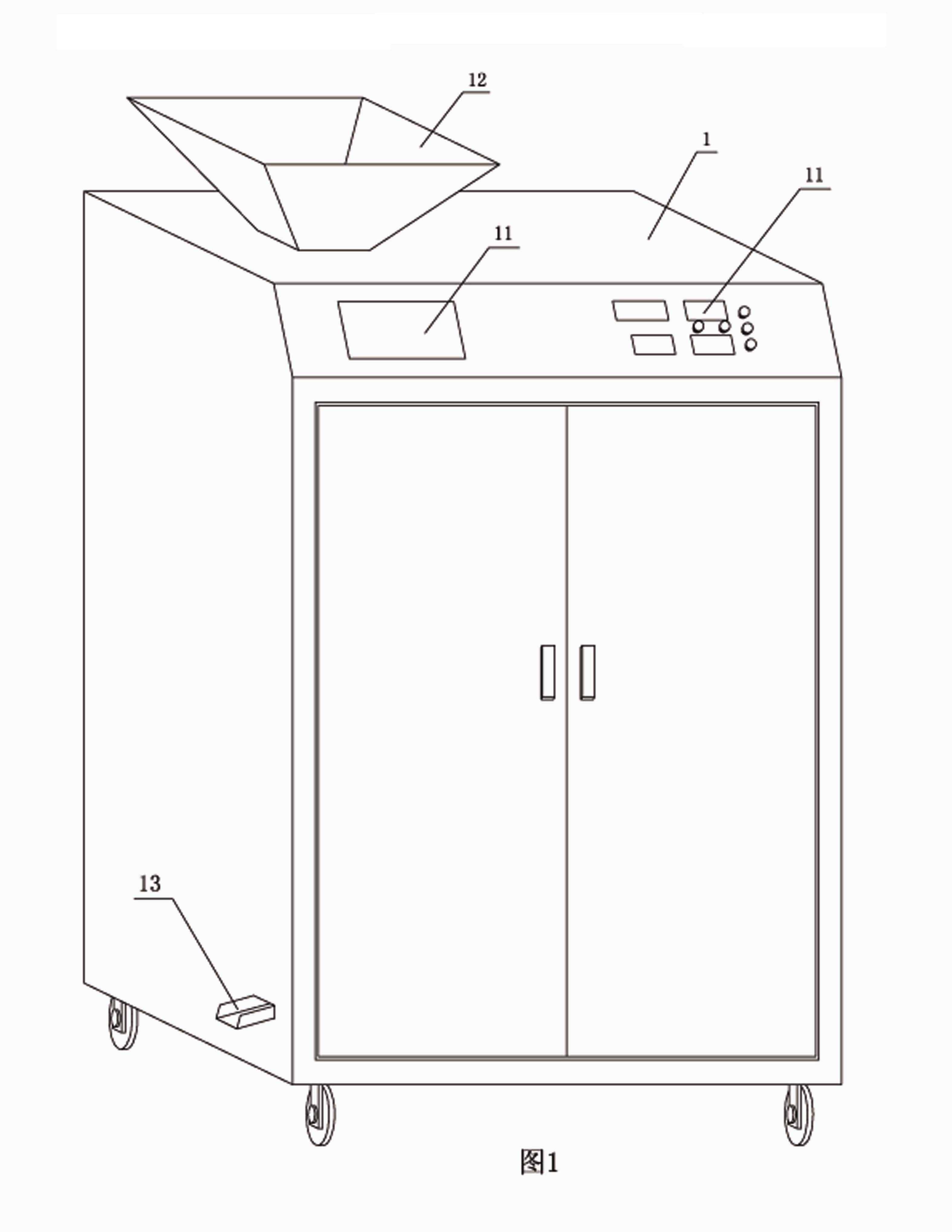

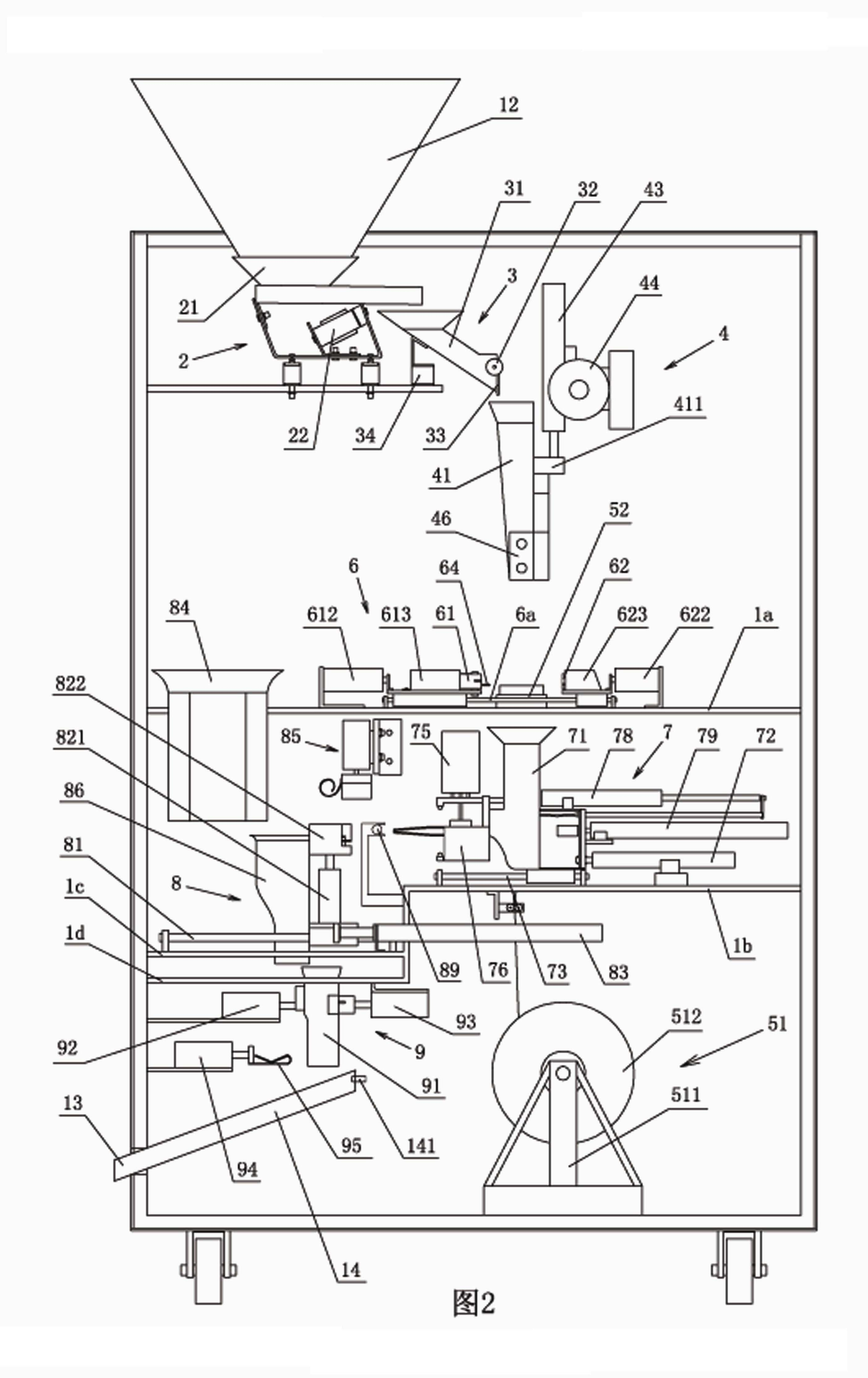

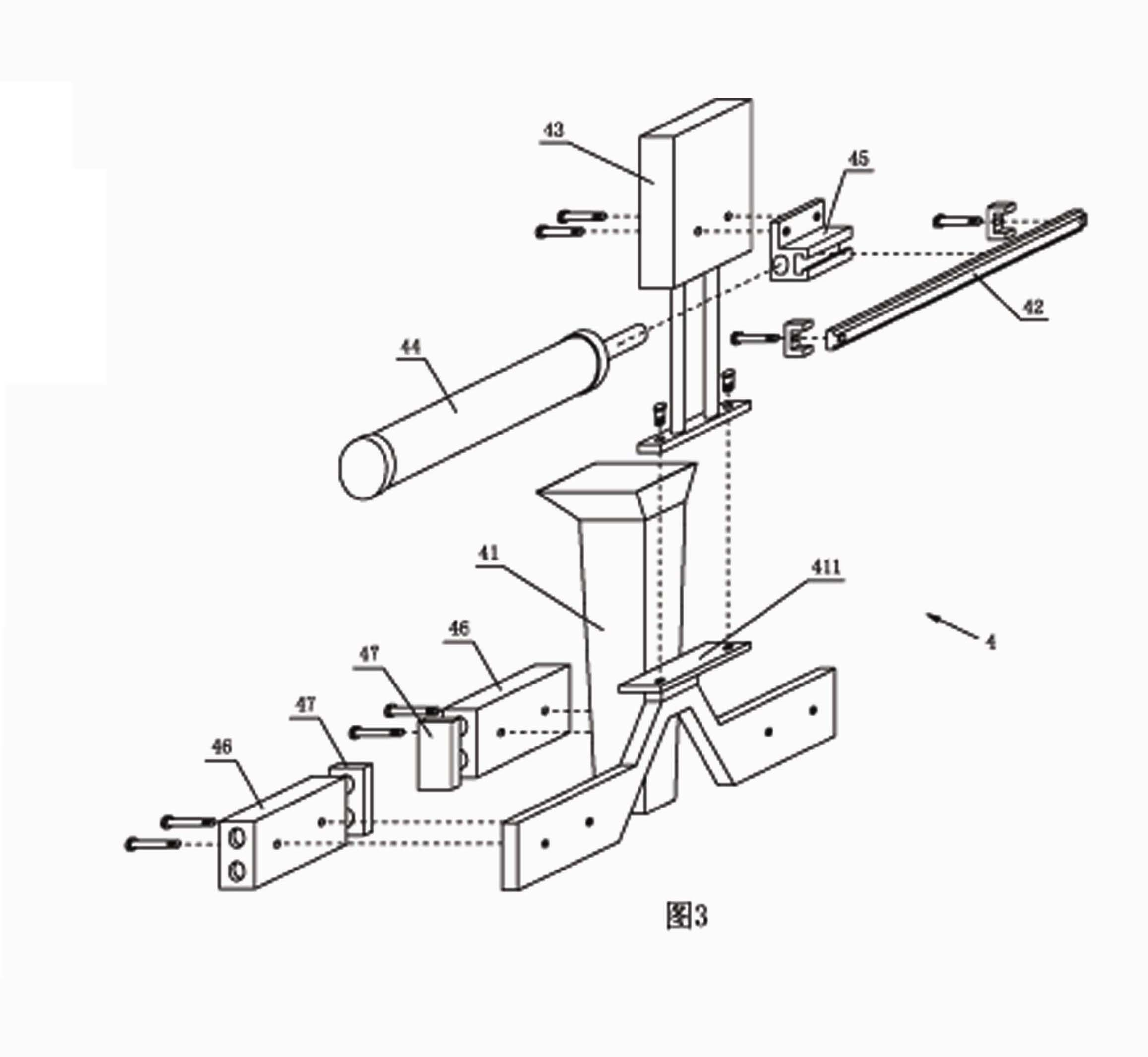

The invention relates to an automatic packaging unit for vacuum packaging of an inner bag and an outer bag, which is characterized by comprising a case, a material hopper, a feeding device, a metering device, an inner bag loading device, an outer bag loading device and a vacuum sealing device, wherein the material hopper is fixed on the top of the case; the lower part of the material hopper is provided with the feeding device, the metering device, the inner bag loading device, the outer bag loading device and the vacuum sealing device successively; the unit also comprises an inner bag film supplying device and an inner bag making device which are matched with the inner bag loading device, and an outer bag conveying device which is arranged between the outer bag loading device and the vacuum sealing device; and an outer bag deposited device and an outer bag gaping device are correspondingly arranged on the outer bag conveying device. The automatic packaging unit has reasonable arrangement of the various actuating mechanisms, automatically organic connection of the multiple steps of feeding, metering, bag making, loading of the inner bag and outer bag vacuum sealing and the like and rapid and stable continuous operation, can automatically complete the inner and outer bag vacuum packaging of the flowing solid granule materials such as tealeaf and the like, and greatly improves the automaticity and the production efficiency of the vacuum packaging operation of the inner bag and outer bag.

Description

technical field [0001] The present invention relates to a kind of equipment that is used for packaging materials such as tea leaves and other liquid solid particles, especially an automatic vacuum packaging machine used for vacuum packaging small liquid solid particles such as tea leaves in inner and outer bags, which can continuously and automatically complete the inner and outer bags. An all-in-one machine for vacuum packaging. Background technique [0002] In order to prolong the shelf life and preservation period of liquid solid small particle materials such as tea, facilitate storage and better adapt to the needs and use of consumers at different levels, the materials are usually vacuum-packed. The existing vacuum packaging method of the inner and outer bags is to firstly put the predetermined amount of material after manual or automatic metering into the empty film inner bag, then fold the film inner bag approximately in the center, and then manually pack the folded in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65B31/04B65B1/04B65B1/08B65B1/32B65B5/04B65B43/04B65B43/18B65B43/26B65B57/00B65B65/00

Inventor 李文峰

Owner 李文峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com