Method for preparing oil cake protein feedstuff through low moisture solid state fermentation

A cake protein, solid-state fermentation technology, applied in animal feed, animal feed, applications, etc., can solve the problems of drying, crushing difficulties, agglomeration, etc., to reduce bacterial pollution, stable product quality, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

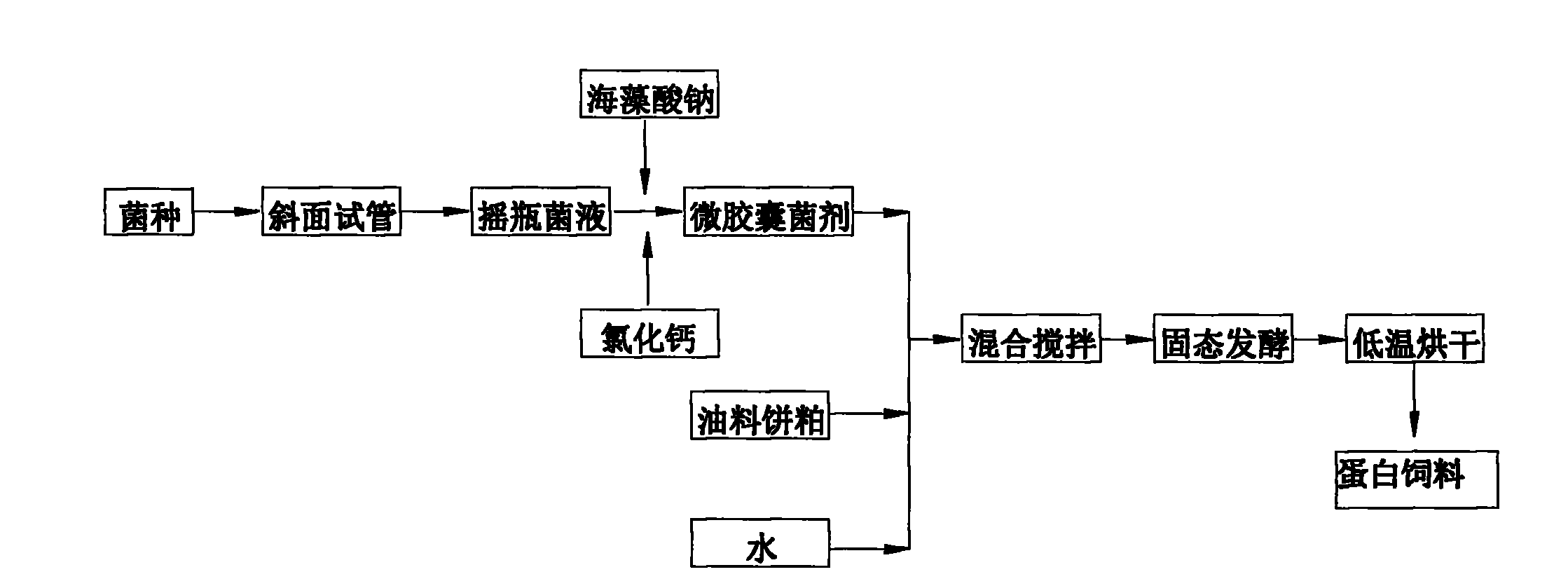

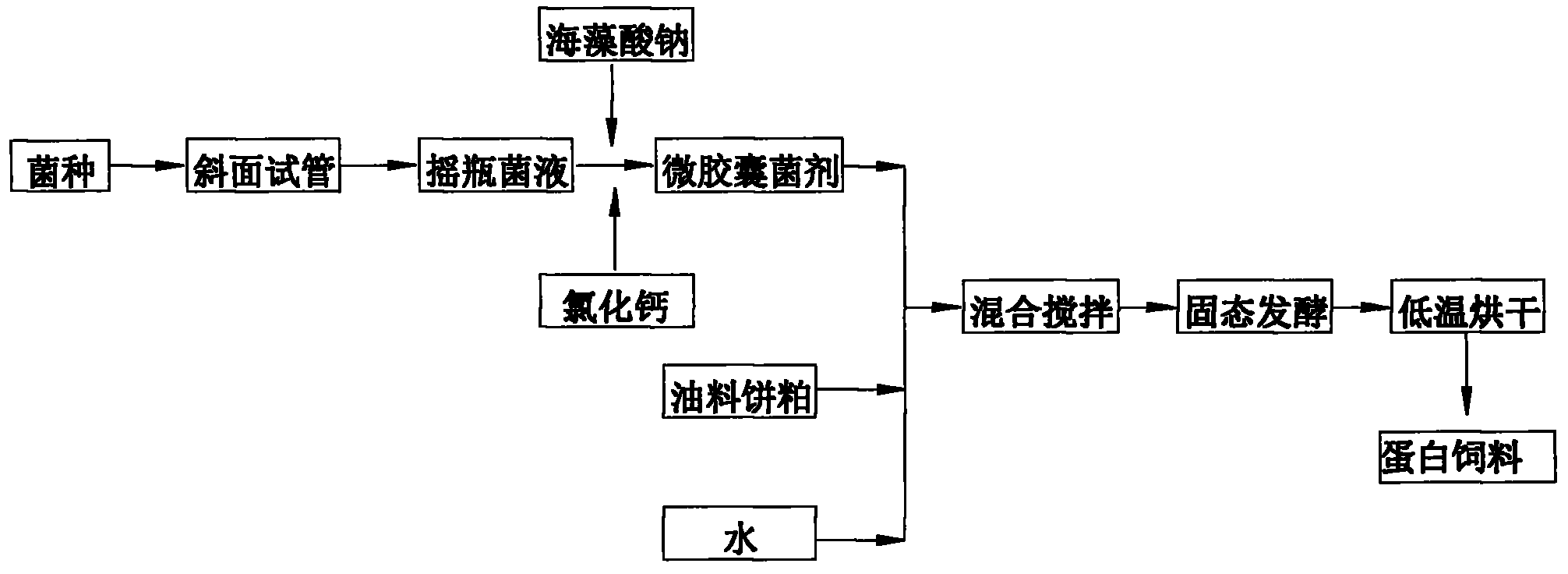

[0037] like figure 1 Shown, a kind of method that low-moisture solid-state fermentation prepares oilseed meal protein feed, it comprises the steps:

[0038] (1) Preparation of bacterial agent: Pick 1 ring colony of Bacillus subtilis from the inclined surface and transfer it to a 250ml triangular flask containing 100ml of glucose beef extract peptone liquid medium, and then place the triangular flask on a shaker at 37°C , 160r / min shake flask culture for 12h (6 ~ 24h can be). Centrifuge the shake flask bacterial liquid to remove the supernatant, and collect the bacterial cells;

[0039] The collected bacteria are washed with sterile physiological saline, centrifuged again, and repeated washing and centrifuging three times to obtain the washed and centrifuged bacteria;

[0040] According to the volume ratio of the washed and centrifuged thalli to sterile saline = 1g: 100mL, the washed and centrifuged thalli were resuspended with sterile saline to obtain a bacterial content of ...

Embodiment 2

[0046] A method for preparing oilseed meal protein feed through low-moisture solid-state fermentation, which comprises the following steps:

[0047] (1) Preparation of bacterial agents: Pick colonies of Bacillus subtilis, Bacillus natto, Saccharomyces cerevisiae, and lactic acid bacteria from the slope and transfer them to the corresponding peptone liquid medium containing glucose beef extract and peptone liquid medium containing glucose beef extract , YPD liquid medium, and MRS liquid medium in the Erlenmeyer flasks (4 Erlenmeyer flasks), then place the Erlenmeyer flasks on a shaker at 37°C, and shake the flasks at 160r / min for 12h (6-24h can be used), respectively ( 4 Erlenmeyer flasks) were centrifuged to remove the supernatant, and the bacteria were collected (collecting 4 Erlenmeyer flasks to obtain mixed bacteria);

[0048] washing the collected bacteria with sterile physiological saline, and centrifuging again; repeating the washing and centrifuging three times to obtai...

Embodiment 3

[0056] A method for preparing oilseed meal protein feed through low-moisture solid-state fermentation, which comprises the following steps:

[0057] (1) Preparation of bacterial agents: Pick 1 ring of colonies from Candida and Saccharomyces cerevisiae from the inclined surface and transfer them to 250ml triangles containing 100ml of YPD liquid medium (glucose beef extract peptone liquid medium can also be used). Then place the triangular flask on a shaker at 28°C, and shake the flask at 160r / min for 12 hours (6-24 hours are acceptable), centrifuge the shake flask bacterial liquid to remove the supernatant, and collect the bacterial cells;

[0058] washing the collected bacteria with sterile physiological saline, and centrifuging again; repeating the washing and centrifuging three times to obtain the washed and centrifuged bacteria;

[0059] According to the volume ratio of the washed and centrifuged thalli to sterile saline = 1g: 500mL, the washed and centrifuged thalli were r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com