Container

a container and notch technology, applied in the field of containers, can solve the problems of a risk of leakage, wear on the side walls of the container, and the container does not contribute to the rigidity or stability of the container,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

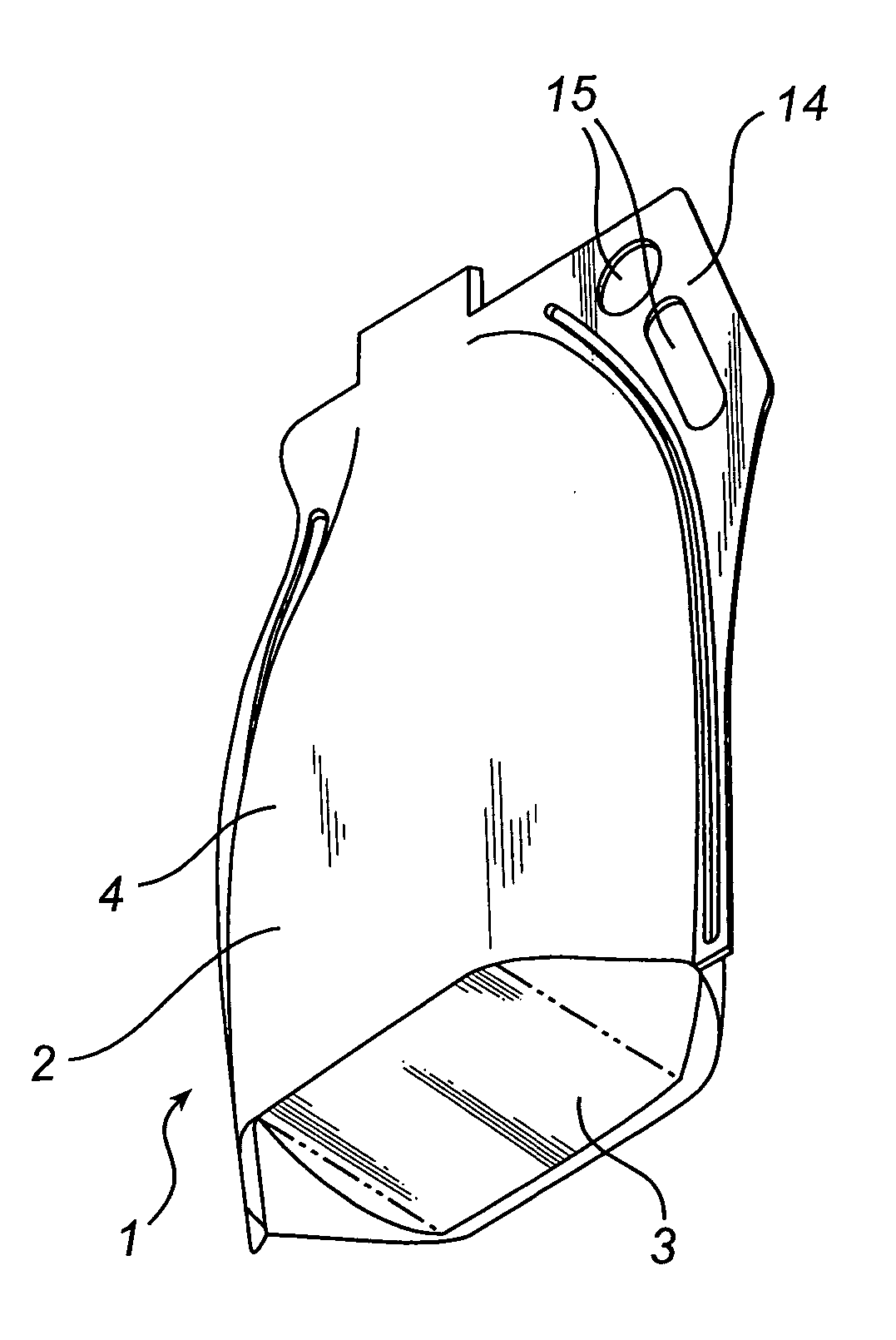

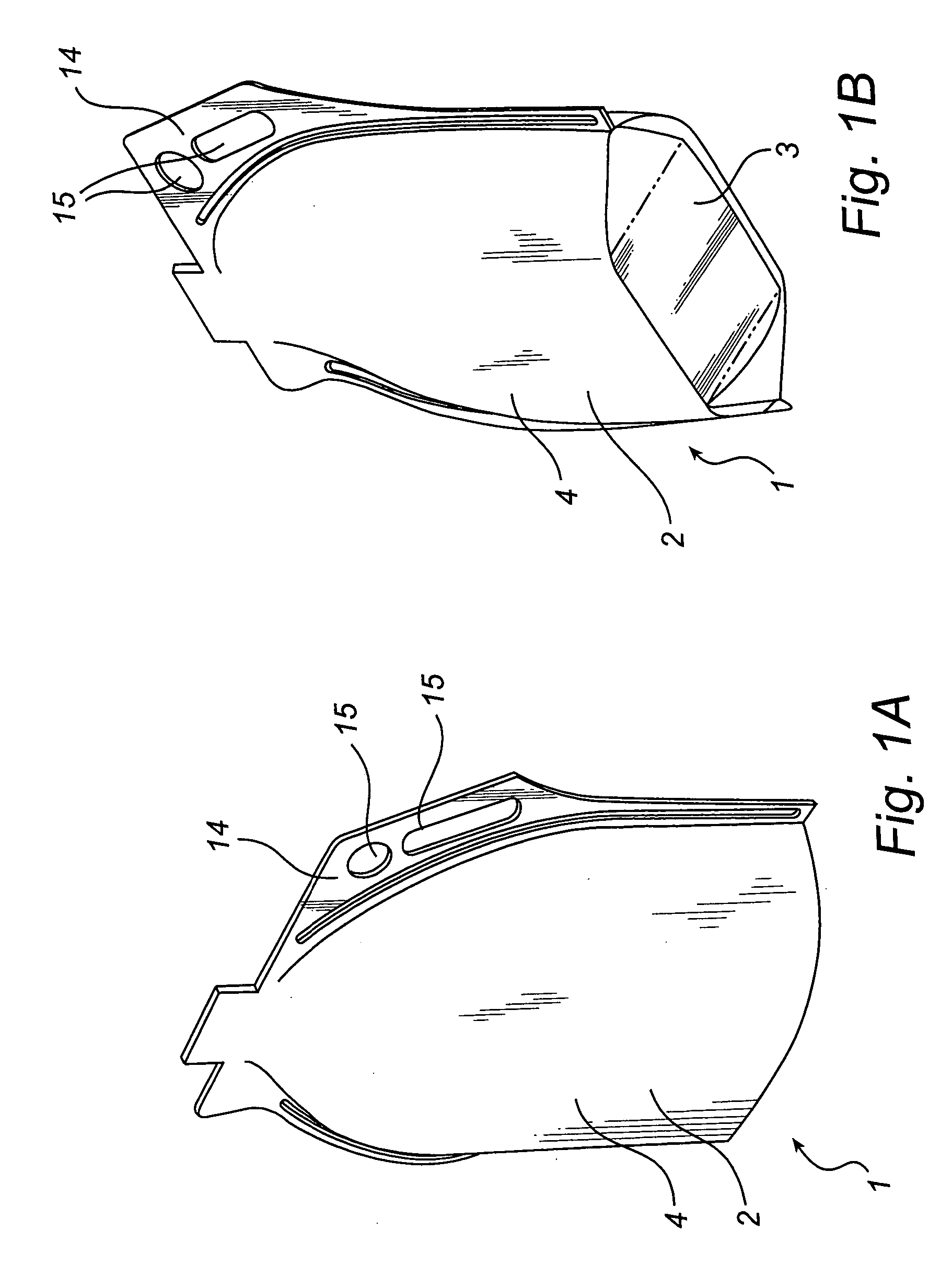

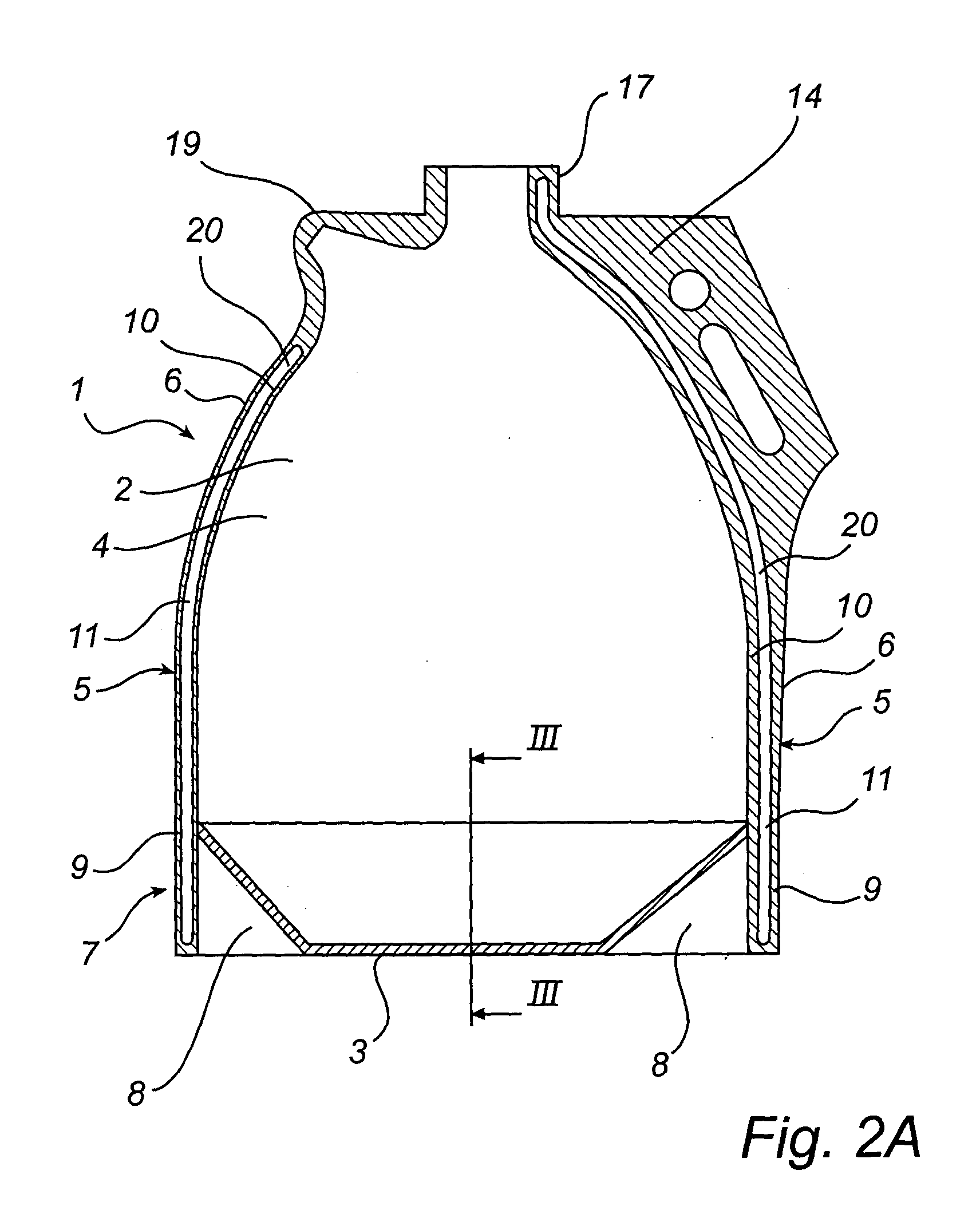

[0010] These and other objects, which will be evident from the following description, are now achieved by a container comprising a compartment which is defined by flexible walls and whose volume depends on the relative position of the walls, two opposite side walls being joined along a common connecting portion, characterised in that a first gas-filled duct means is arranged in the connecting portion along at least a first side of the container.

[0011] As a result, the first gas-filled duct means forms a kind of backbone in the container which gives stiffness and stability in each side of the container in which the gas-filled duct means is arranged. This counteracts the container losing shape and appearance during transport or careless handling. Moreover, the risk of notches by wrinkle-related wear is reduced. By arranging the stiffening in the form of a gas-filled duct means, no new type of material or no further amount of material is added. The inventive container can thus be intro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com