Antimicrobial polyethylene film and preparing technique thereof

A polyethylene film and polyethylene technology, used in layered products, other household appliances, synthetic resin layered products, etc., can solve the problems of anti-corrosion and anti-deterioration of the contents, and achieve no toxic side effects, not easy to change color, Antibacterial effect Long lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

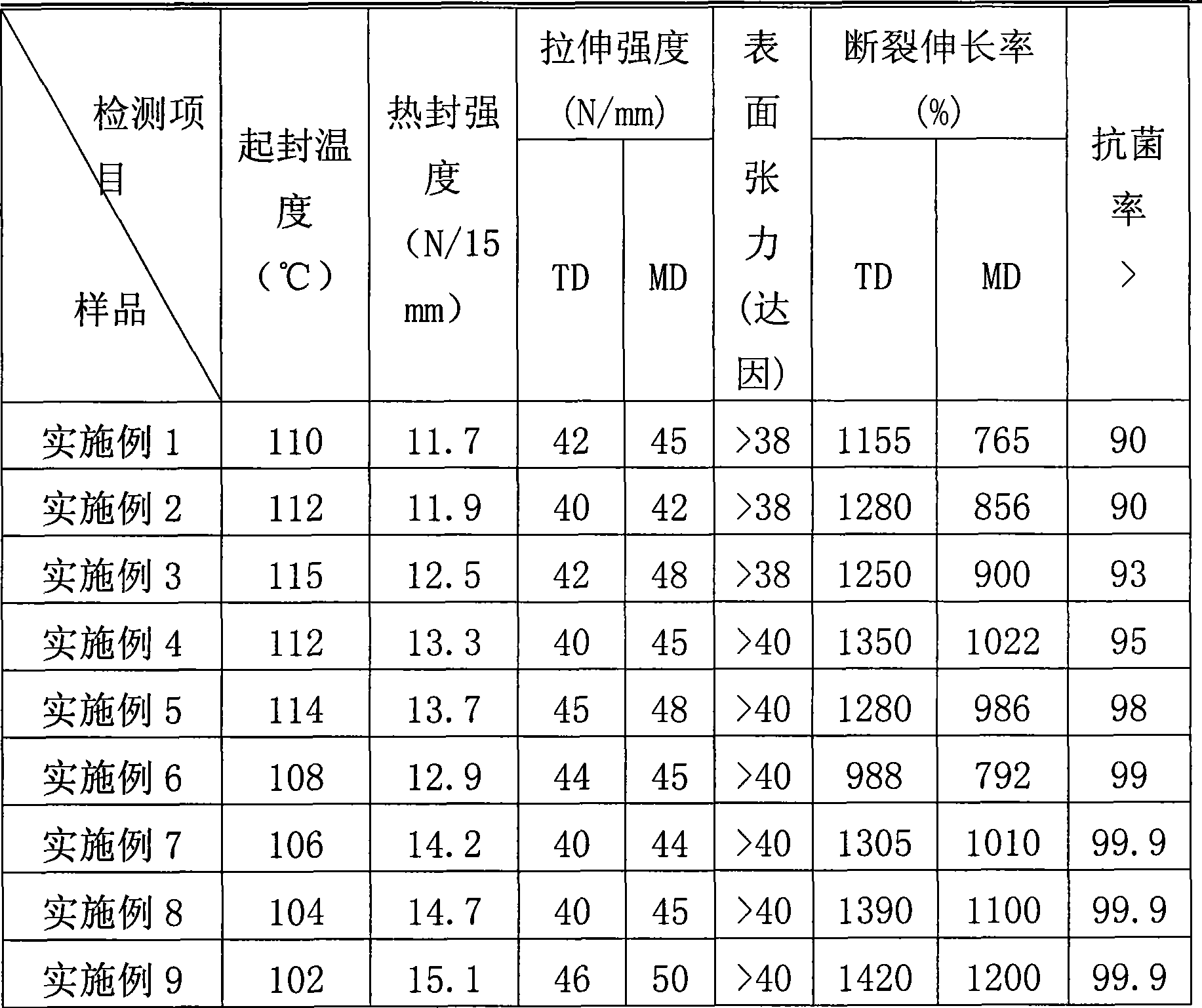

Embodiment 1

[0040] The production of antibacterial polyethylene film is as follows: feeding process, material plasticizing extrusion process, inflation traction process, air ring cooling process, herringbone splint process, traction roller traction process, corona treatment process, film winding process:

[0041] In the feeding process:

[0042] The outer layer is blended with a formula weight ratio of LDPE:LLDPE=1:1;

[0043] The middle layer is blended with LDPE:LLDPE=1:1 formula weight ratio;

[0044] The inner layer is made of LDPE, LLDPE, MLLDPE, slip agent, antibacterial agent = 1:1:1:0.01:0.05;

[0045] In the material plasticizing extrusion process, the temperature of the barrel is set to 4 heating zones, which are: zone 1: 135°C; zone 2: 155°C; zone 3: 155°C; zone 4: 160°C; The heating zone of the die is 155°C; the temperature of the die head is set to 4 zones, respectively, the temperature of the first heating zone is 150°C; the temperature of the second zone of the die head h...

Embodiment 2

[0047] The outer layer is blended with the formula weight ratio of LDPE:LLDPE=1:0.5;

[0048] The middle layer is blended with the formula weight ratio of LDPE:LLDPE=1:1.2;

[0049] The inner layer is made of LDPE, LLDPE, MLLDPE, slippery agent, antibacterial agent = 1:0.5:1.0:0.01:0.08; the rest is the same as in Example 1.

Embodiment 3

[0051] The outer layer is blended with the formula weight ratio of LDPE:LLDPE=1:0.5;

[0052] The middle layer is blended with the formula weight ratio of LDPE:LLDPE=1:1.4;

[0053] The inner layer uses LDPE, LLDPE, MLLDPE, slippery agent, antibacterial agent = 1:1:1.5:0.01:0.10; the rest is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com