Antibacterial master batch based on guanidinium polymer and preparation method thereof

A technology of antibacterial masterbatch and compound antibacterial agent, which is applied in the field of antibacterial masterbatch and its preparation, can solve the problems of low melting point of guanidine-based polymers, difficulty in cleaning, and reduced antibacterial efficiency, and achieve good washing resistance, good antibacterial effect, The effect of high antibacterial efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

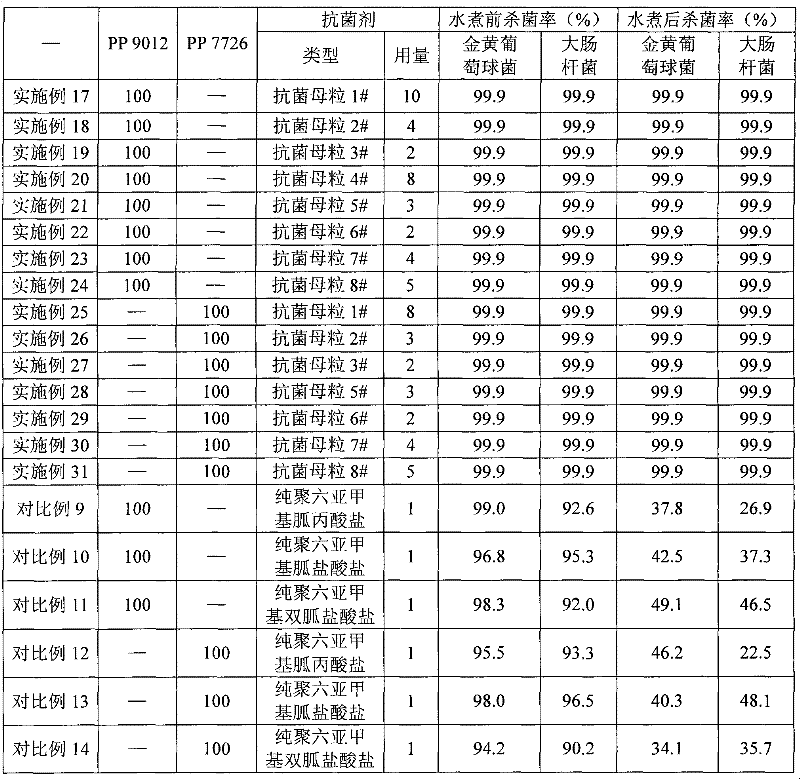

Examples

Embodiment 1

[0038] (1) Weigh 1000.0g (4.65M) of polyhexamethyleneguanidine propionate (Shanghai Gaoju F3000), add it to 3000mL deionized water solution, stir to dissolve it, and call it solution A; (2) otherwise call it Sodium silicate (chemically pure) 700.0g (2.46M), was added to 3000mL deionized water, stirred to dissolve, called solution B; (3) at room temperature (about 25°C), solution A and solution B Mix and fully stir for 30 minutes to form solution C; (4) weigh ZnSO 4 (Chemical pure) 1800.0g (6.26M), added to 3000mL deionized water, stirred to dissolve, then slowly poured into solution C, and vigorously stirred for 5min, the precipitate was filtered, dried, and pulverized to obtain poly Hexamethyleneguanidine propionate / zinc polysilicate composite antibacterial agent (composite antibacterial agent 1).

Embodiment 2

[0040] (1) Weigh 1000.0g (4.65M) of polyhexamethyleneguanidine propionate (Shanghai Gaoju F3000), add it to 3000mL deionized water solution, stir to dissolve it, and call it solution A; (2) otherwise call it Add 1000.0g (3.52M) of sodium silicate (chemically pure) into 5000mL of deionized water, stir to dissolve, and call it solution B; (3) Mix solution A and solution B, and stir well at 50°C for 1 hour, Form solution C; (4) take by weighing ZnSO 4 (Chemical pure) 1200.0g (4.17M), added to 3000mL deionized water, stirred to dissolve, then slowly poured into solution C, and vigorously stirred for 10min, the precipitate was filtered, dried, and pulverized to obtain poly Hexamethyleneguanidine propionate / zinc polysilicate composite antibacterial agent (composite antibacterial agent 2).

Embodiment 3

[0042] (1) Weigh 1000.0g (6.35M) of polyhexamethyleneguanidine hydrochloride (Shanghai Gaoju F1000), add it to 3000mL deionized water solution, stir to dissolve it, and call it solution A; Sodium silicate (chemically pure) 1500.0g (5.28M), added to 6000mL deionized water, stirred to dissolve, called solution B; (3) at room temperature (about 25°C), mix solution A and solution B , and fully stirred for 1.5h to form solution C; (4) weigh Ca(NO 3 ) 2 (Chemical pure) 1200.0g (5.08M), added to 3000mL deionized water, stirred to dissolve, then slowly poured into solution C, and vigorously stirred for 10min, the precipitate was filtered, dried, and pulverized to obtain poly Hexamethyleneguanidine hydrochloride / calcium polysilicate composite antibacterial agent (composite antibacterial agent 3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com