Flame-resistant polyester-olycarbonate compositions, methods of manufacture, and articles thereof

A technology of polycarbonate and composition, which is applied in the field of polyester-polycarbonate flame retardant composition, preparation and its products, and can solve the problems of low impact resistance or heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

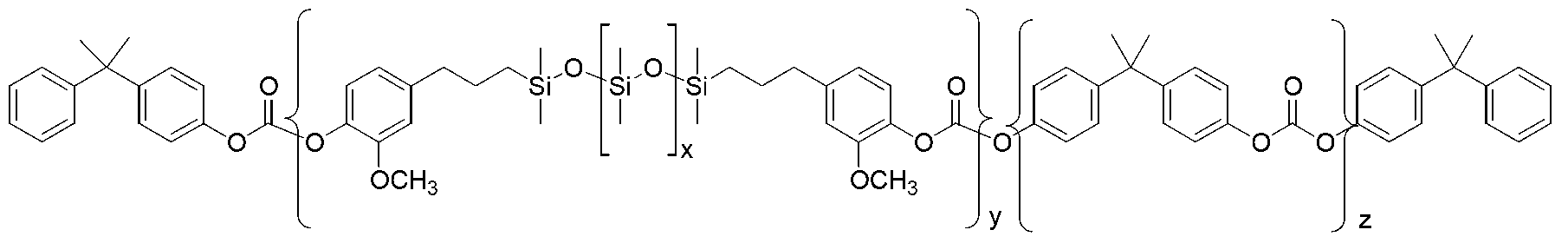

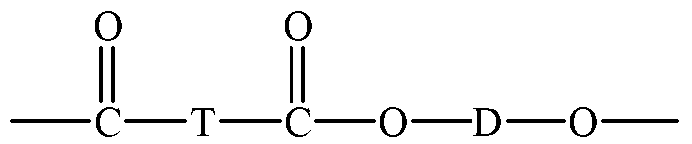

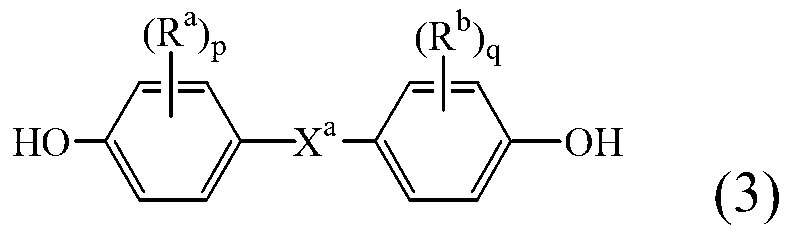

Method used

Image

Examples

Embodiment 1-12 and comparative example C1-C5

[0194] Compositions with the formulations (wt%) shown in Table 3 were prepared as described above, except that the PET-containing compositions were processed at a temperature 20°C higher than the PBT-containing compositions, including extrusion and In molding operation. In addition to the components shown, each composition was formulated with 0.15 wt% MZP, 0.8 wt% TSAN, 0.15 wt% AO and 0.27 wt% UVS. The results are also shown in Table 3.

[0195] table 3.

[0196]

[0197] As can be seen from the data in Table 3, when organophosphorus (BPA-DP) is present in the composition of C1 without impact modifier, the composition achieves a flammability rating of V0, but the impact resistance Reduced compared with Examples 1-11. In comparative examples C2-C5, impact modifiers were added to improve impact resistance, but the composition did not simultaneously achieve the desired balance of properties (V0 flammability rating, good impact resistance (greater than 400 J / m, especially g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com