Environmentally-friendly ultralight flame-retardant rubber sole material and manufacturing method thereof

A technology for flame retardant rubber and sole material, which is applied in the field of environment-friendly ultra-light flame retardant rubber sole material and its manufacturing field, and can solve the problems of poor flame retardant performance, heavy sole, and poor storage stability of neoprene rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

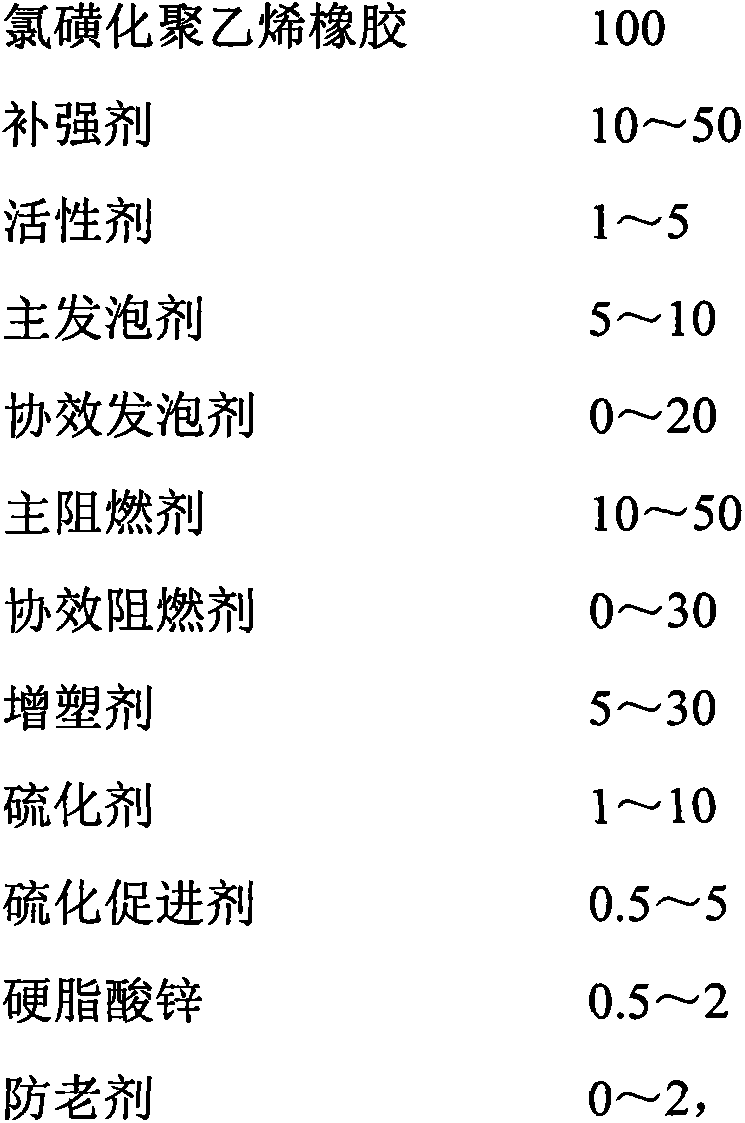

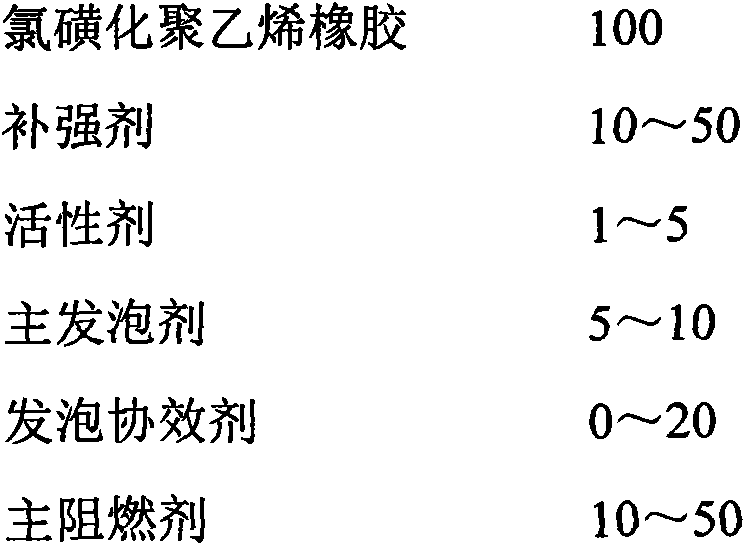

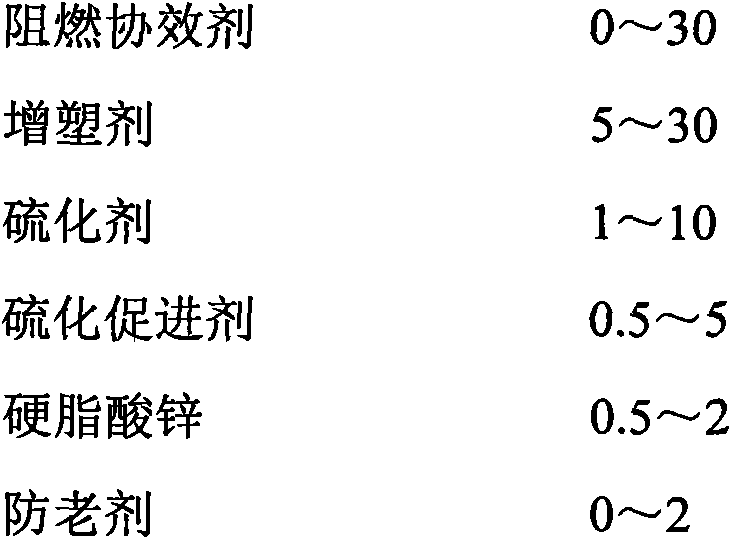

Method used

Image

Examples

Embodiment 1

[0021] The composition (mass ratio) is: 100 parts of CSM, 10 parts of white carbon black, 3.0 parts of PEG, 5.0 parts of TOTM, 5.0 parts of magnesium oxide, 0.5 parts of TAIC, 2.0 parts of pentaerythritol, 1.0 parts of zinc stearate, and 2.0 parts of sulfur 1.0 part of anti-aging agent NBC, 0.5 part of microcrystalline wax.

[0022] Weigh according to the above ratio, mix according to the above process, and test the process positive vulcanization time t of the mixed rubber at 160°C by a oscillating disc type rotorless vulcanizer. 90 for 540s, and then molded at 160°C. After the molded sample was placed at room temperature (around 25°C) for 24 hours, its relative density was measured to be 1.244g / cm 3 , hardness (Shao C) 69.4; according to GB / T1040 test its tensile strength is 26.48MPa, elongation at break is 558%; according to GB / T3903.12-2005 test the right-angle tear strength of vulcanized rubber is 59.4N / mm .

Embodiment 2

[0024] The composition (mass ratio) is: 100 parts of CSM, 10 parts of white carbon black, 10 parts of AC, 8 parts of sodium bicarbonate, 3.0 parts of PEG, 5.0 parts of TOTM, 5.0 parts of magnesium oxide, 0.5 parts of TAIC, 2.0 parts of pentaerythritol, hard 1.0 parts of zinc fatty acid, 2.0 parts of sulfur, 1.0 parts of anti-aging agent NBC, 0.5 parts of microcrystalline wax.

[0025] Weigh according to the above ratio, mix according to the above process, and test the process positive vulcanization time t of the mixed rubber at 160°C by a oscillating disc type rotorless vulcanizer. 90 It is 403s, and then molded at 160°C. After the molded sample was placed at room temperature (around 25°C) for 24 hours, its relative density was measured to be 0.443g / cm 3 , hardness (Shao C) 43.8; according to GB / T1040 test its tensile strength is 6.0MPa, elongation at break is 465%; according to GB / T3903.12-2005 test the right-angle tear strength of vulcanized rubber is 15.4N / mm .

Embodiment 3

[0027] The composition (mass ratio) is: 100 parts of CSM, 10 parts of white carbon black, 10 parts of AC, 12 parts of sodium bicarbonate, 3.0 parts of PEG, 5.0 parts of TOTM, 5.0 parts of magnesium oxide, 0.5 parts of TAIC, 2.0 parts of pentaerythritol, hard 1.0 part of zinc fatty acid, 2 parts of sulfur, 1.0 part of anti-aging agent NBC, 0.5 part of microcrystalline wax.

[0028] Weigh according to the above ratio, mix according to the above process, and test the process positive vulcanization time t of the mixed rubber at 160°C by a oscillating disc type rotorless vulcanizer. 90 for 420s, and then molded at 160°C. After the molded sample was placed at room temperature (around 25°C) for 24 hours, its relative density was measured to be 0.379g / cm 3 , hardness (Shore C) 35.0; according to GB / T1040, the tensile strength is 5.0MPa, and the elongation at break is 488%; according to GB / T3903.12-2005, the right-angle tear strength of the vulcanized rubber is 12.7N / mm . The open p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Right angle tear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com