Low-RDA friction type silicon dioxide and preparation method thereof

A silica and silane coupling agent technology, applied in chemical instruments and methods, cosmetic preparations, inorganic chemistry, etc., can solve the problem of not being suitable for people with weak teeth, increasing the production cost of toothpaste, affecting consumer experience, etc. problems, to achieve the effect of reducing friction capacity, less energy consumption in production, and controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

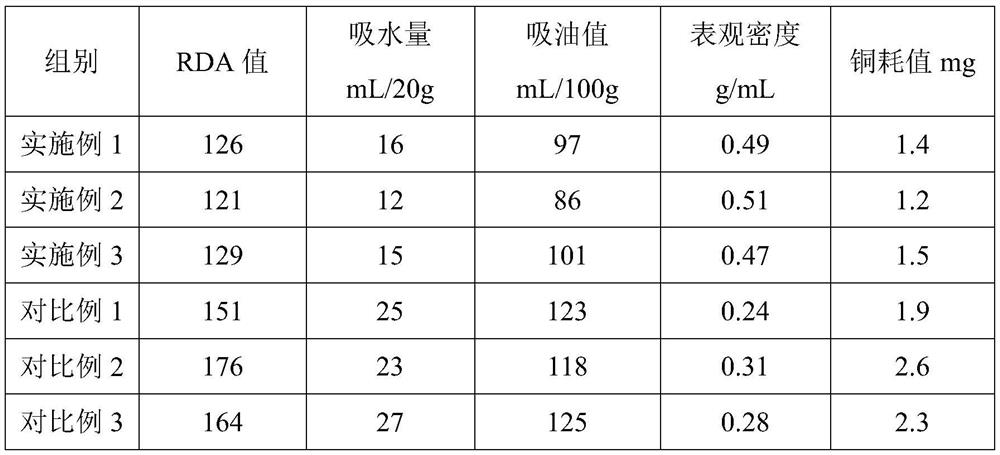

Examples

Embodiment 1

[0028] Embodiment 1, a kind of low RDA frictional silica and its preparation method

[0029] The preparation method of described low RDA friction type silica, comprises the following steps:

[0030] S1, configuration molar concentration is the sulfuric acid solution of 0.70mol / L;

[0031] S2, adding deionized water to the water glass for dilution and dissolving, aging for 5h, and taking the aged water glass and adding water to dilute it to form a water glass solution with a mass concentration of 0.71mol / L;

[0032] S3, adding volume to the reaction tank is 12m 3 For the sulfuric acid solution prepared in step S1, the stirring device was turned on, the stirring frequency was 35 Hz, and the temperature was raised to 40° C.;

[0033] S4, drip the water glass solution that step S2 makes in the sulfuric acid solution after heating up in step S3, the dripping speed of water glass solution is 22m 3 / h, and the amount added to the water glass solution is 0.8m 3 When adding the sil...

Embodiment 2

[0035] Embodiment 2, a kind of low RDA frictional silica and its preparation method

[0036] The preparation method of described low RDA friction type silica, comprises the following steps:

[0037] S1, configuration molar concentration is the sulfuric acid solution of 0.74mol / L;

[0038] S2, adding deionized water to the water glass for dilution and dissolving, aging for 6.5h, and taking the aged water glass and adding water to dilute it to form a water glass solution with a mass concentration of 0.75mol / L;

[0039] S3, adding volume to the reaction tank is 12m 3 For the sulfuric acid solution prepared in step S1, the stirring device was turned on, the stirring frequency was 38 Hz, and the temperature was raised to 43° C.;

[0040] S4, drip the water glass solution that step S2 makes in the sulfuric acid solution after heating up in step S3, the dripping speed of water glass solution is 24m 3 / h, and the amount added to the water glass solution is 0.8m 3When adding the si...

Embodiment 3

[0042] Embodiment 3, a kind of low RDA frictional silica and its preparation method

[0043] The preparation method of described low RDA friction type silica, comprises the following steps:

[0044] S1, configuration molar concentration is the sulfuric acid solution of 0.80mol / L;

[0045] S2, adding deionized water to the water glass for dilution and dissolving, aging for 8h, and taking the aged water glass and adding water to dilute it to form a water glass solution with a mass concentration of 0.77mol / L;

[0046] S3, adding volume to the reaction tank is 12m 3 For the sulfuric acid solution prepared in step S1, the stirring device was turned on, the stirring frequency was 40 Hz, and the temperature was raised to 45° C.;

[0047] S4, drip the water glass solution that step S2 makes in the sulfuric acid solution after heating up in step S3, the dripping speed of water glass solution is 25m 3 / h, and the amount added to the water glass solution is 0.8m 3 When adding the sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com