Halogen-free flame retardant ethylene propylene diene monomer (EPDM) material and preparation method thereof

A technology of EPDM rubber and flame retardant, applied in the field of halogen-free flame retardant EPDM rubber materials and preparation, can solve the problem of low flame retardant performance, not reaching UL-94V-0 level, flame retardant three The problem of small molecule precipitation in ethylene-propylene rubber materials has achieved the effect of broadening the scope of application and improving the flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

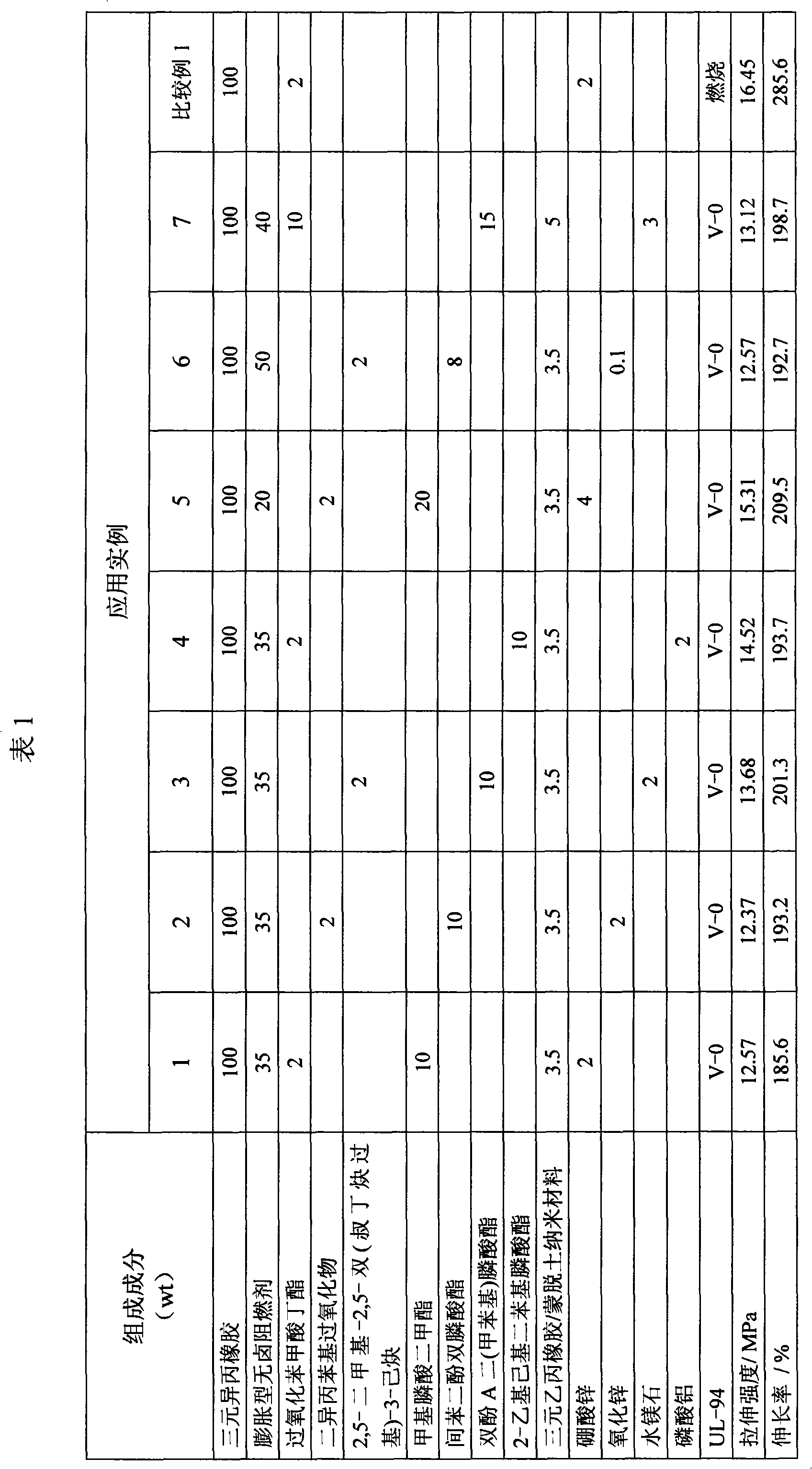

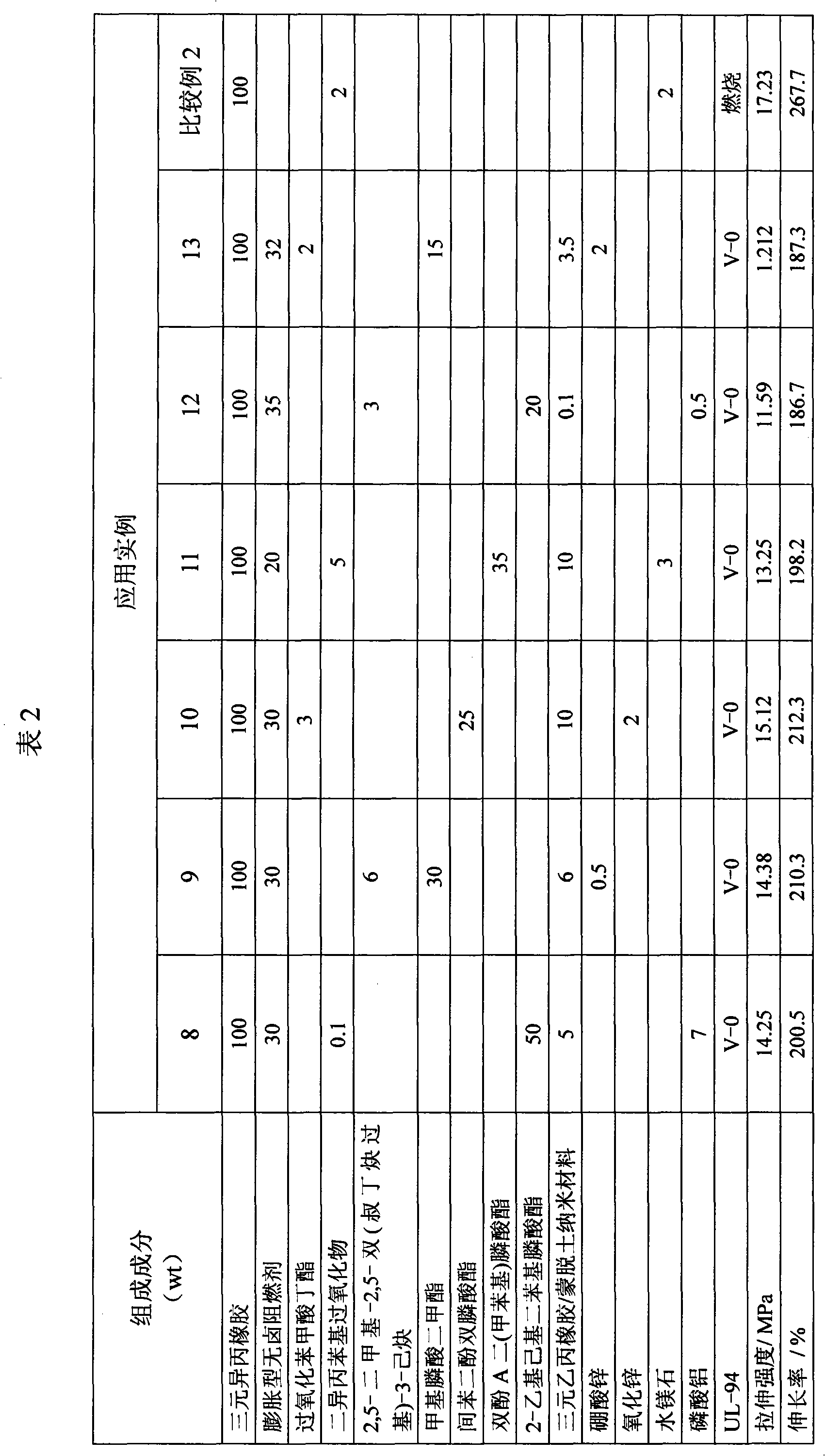

Embodiment 1~13 and comparative example 1、2

[0024] See Table 1 and Table 2. The compounding components of the rubber materials listed in the table are the values based on 100 parts by mass of EPDM rubber. According to the ratio specified in Table 1 and Table 2, the expansion type halogen-free Flame retardant, EPDM rubber / montmorillonite nanocomposite (commercially available) and part of phosphonate are premixed in a high-speed mixer, and the premixed phosphonate accounts for 40% of the amount of phosphonate added~ 60%, the mixing speed is 5000 rpm, and the mixing time is 20-50 minutes, then extrude the EPDM rubber, the flame retardant mixture obtained above, the remaining phosphonate, the crosslinking agent, and the filler with an extruder Mixing, the mixing temperature is 150 ~ 220 ℃. During this extrusion mixing process, the crosslinking agent and the remaining phosphonate are added from the side feeding port of the extruder, and the remaining materials are fed from the feeding port of the extruder. Then injection ...

Embodiment 3

[0027] The third monomer of the EPDM rubber described in Example 3 is ethylidene norbornene (ENB), the ethylene content is 45%, and the Mooney viscosity value is 25; the expansion type halogen-free flame retardant is a three-source matching Expansion system ANTI-6 (produced and sold by Shanghai Research Institute of Chemical Industry); the particle size of EPDM rubber / montmorillonite nanomaterial is 70nm. Others are listed in Table 1.

[0028] The third monomer of the EPDM rubber described in Examples 4 and 5 is dicyclopentadiene (DCPD), the ethylene content is 80%, and the Mooney viscosity value is 90; the expansion type halogen-free flame retardant is three sources Matching expansion system JLA-PNP1 (produced and sold by Hangzhou Jieersi Flame Retardant Chemical Co., Ltd.); the particle size of EPDM / montmorillonite nanomaterials is 80nm. Others are listed in Table 1.

[0029] The third monomer of the EPDM rubber described in Examples 6 and 7 is 3,7-dimethyl-1,6-octadiene, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com