Phosphorus-nitrogen system biology based flame retardant as well as synthesis method and application thereof

A synthesis method and bio-based technology, which can be used in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc. Processing and use problems, to achieve good processing performance and dispersibility, reduce the burden on the environment and resources, the synthesis process is simple and low toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

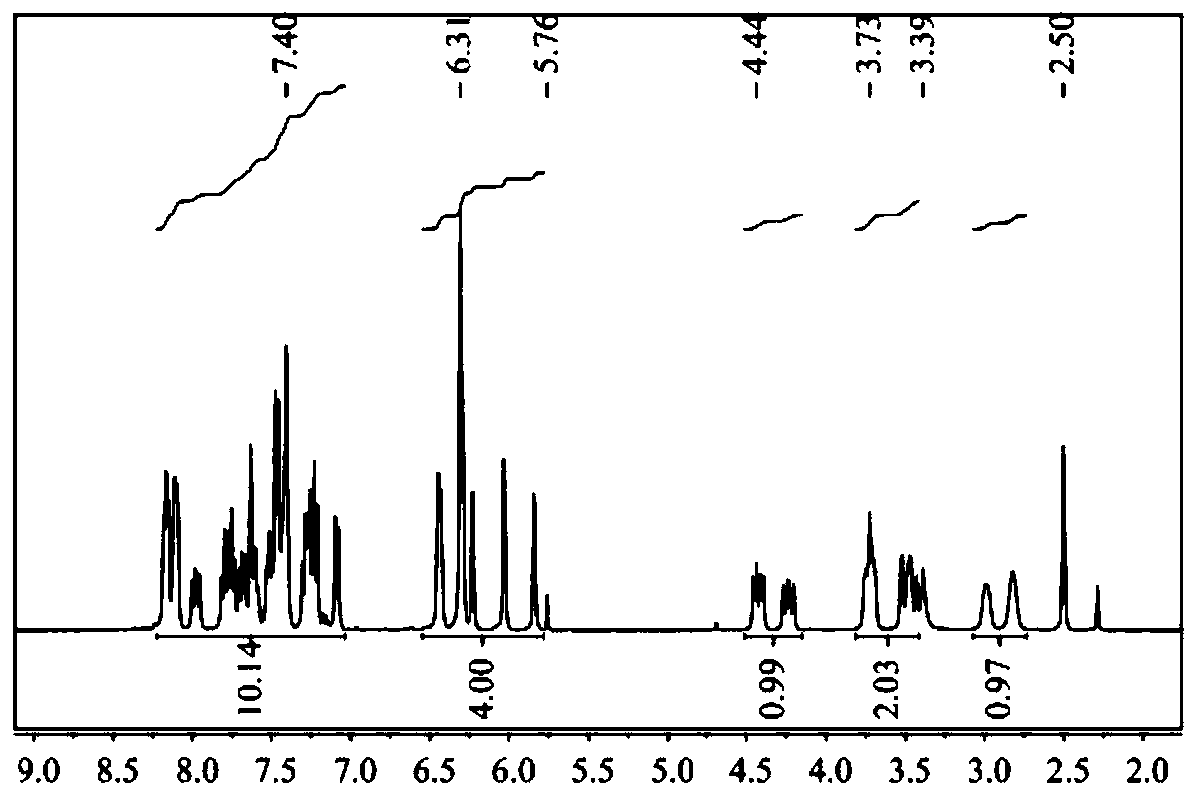

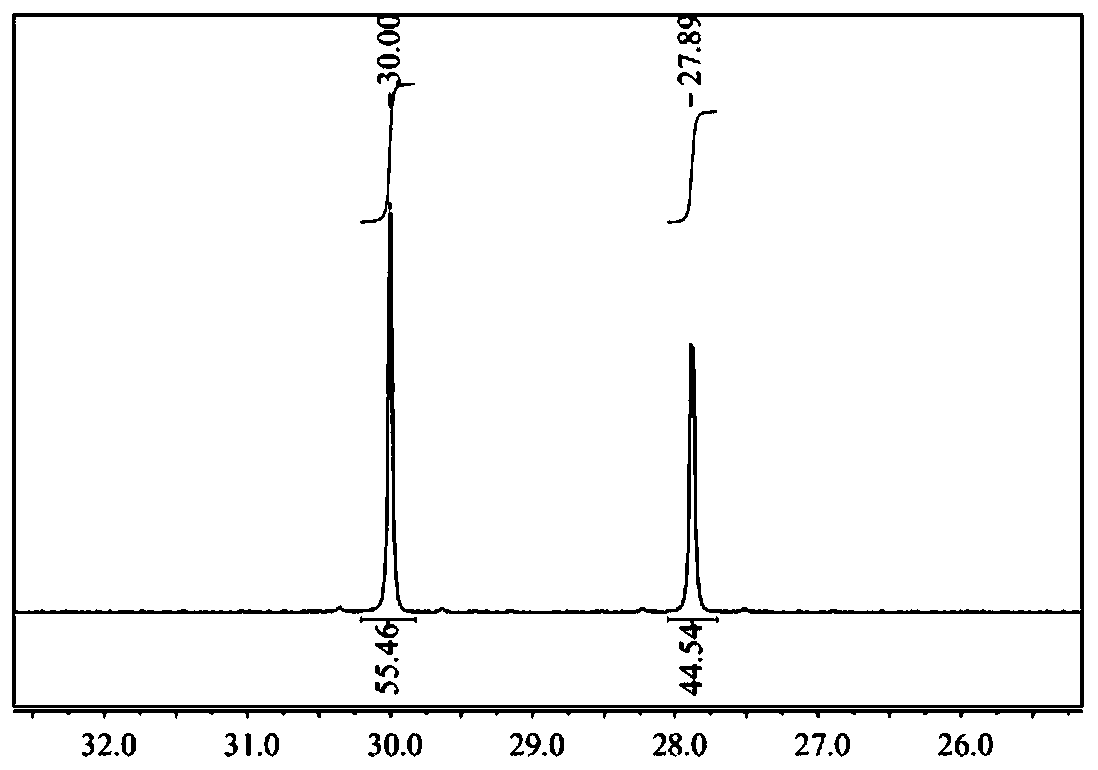

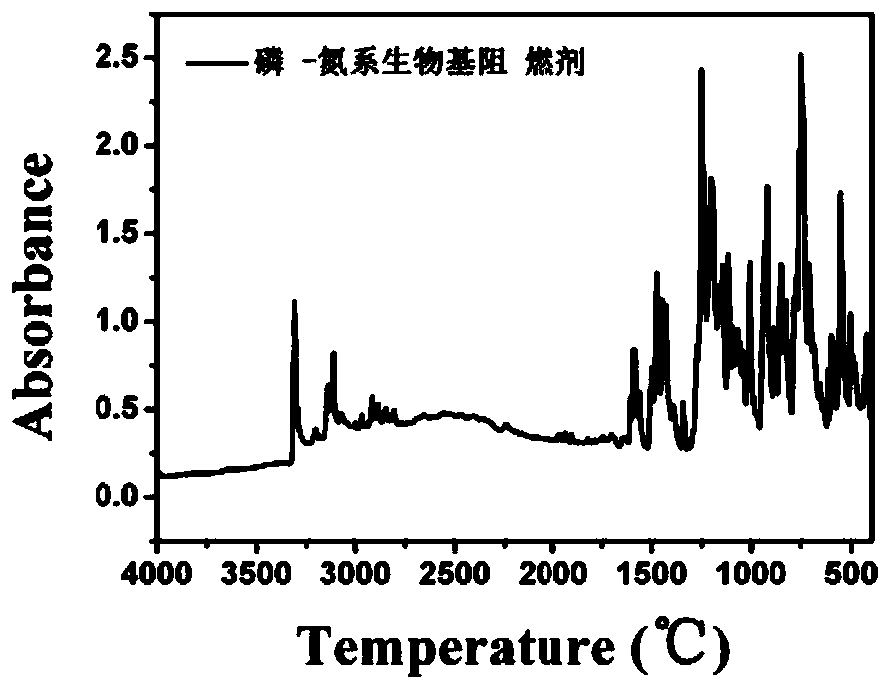

[0061] At room temperature, 1 mol of terephthalaldehyde was completely dissolved in 400 mL of ethanol, 2 mol of furfurylamine was added thereto, stirred evenly by magnetic force, and the temperature was raised to 80° C. for 4 h. Keeping the reaction temperature at 80°C, 2.4mol of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide was added into the reaction flask, and the reaction was continued for 8 hours after it was completely dissolved. After the reaction was finished, the solvent was removed by rotary evaporation, washed three times with 2% aqueous sodium hydroxide solution, then washed three times with deionized water, and dried to obtain product 1, whose structural formula is as follows:

[0062]

Embodiment 2

[0064] At room temperature, 1 mol of benzaldehyde was completely dissolved in 200 mL of methanol, 1 mol of furfurylamine was added thereto, stirred evenly by magnetic force, and the temperature was raised to 60° C. to react for 4 h. Add 1.2 mol of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into the reaction flask, and after completely dissolving, raise the temperature to 80°C and continue the reaction for 12 hours. After the reaction was finished, the solvent was removed by rotary evaporation, washed three times with 2% aqueous sodium hydroxide solution, then washed three times with deionized water, and dried to obtain product 2, whose structural formula is as follows:

[0065]

Embodiment 3

[0067] At room temperature, 1 mol of phenylacetaldehyde was completely dissolved in 200 mL of methanol, 1 mol of furfurylamine was added thereto, stirred evenly by magnetic force, and the temperature was raised to 80° C. to react for 4 h. Add 1 mol of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into the reaction flask, and after it is completely dissolved, continue to react at 80°C for 8h. After the reaction was finished, the solvent was removed by rotary evaporation, washed three times with 2% aqueous sodium hydroxide solution, then washed three times with deionized water, and dried to obtain product 3, whose structural formula is as follows:

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com