Black halogen-free epoxy resin composition and covering film prepared from same

A halogenated epoxy resin and epoxy resin technology, which is applied in the field of black halogen-free epoxy resin composition and the cover film prepared by using the same, can solve the problems of immature price and high cost, and achieve excellent dimensional stability and good mechanical properties. Performance, effect of high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The composition described above can be used in the preparation of a cover film. The desired components are mixed using an organic solvent to form a black liquid dispersion of the composition of the present invention, and the dispersion is coated onto a polyimide insulating film using a coating device. The insulating film coated with the dispersion is passed through an online drying oven, heated at 80-160° C. for 2 to 8 minutes, thereby removing the organic solvent and drying the composition to form a layer containing the composition in a semi-cured state, followed by Laminate with release paper at 80-100°C, and roll to get a black cover film.

[0050] The dry thickness of the coating film of the composition in the above cover film is 5-45 μm, preferably 10-35 μm.

[0051] The thickness of the polyimide insulating film used above is 10-100 μm, the thickness of the release paper is 50-150 μm, and the thickness of the glue is 10-35 μm.

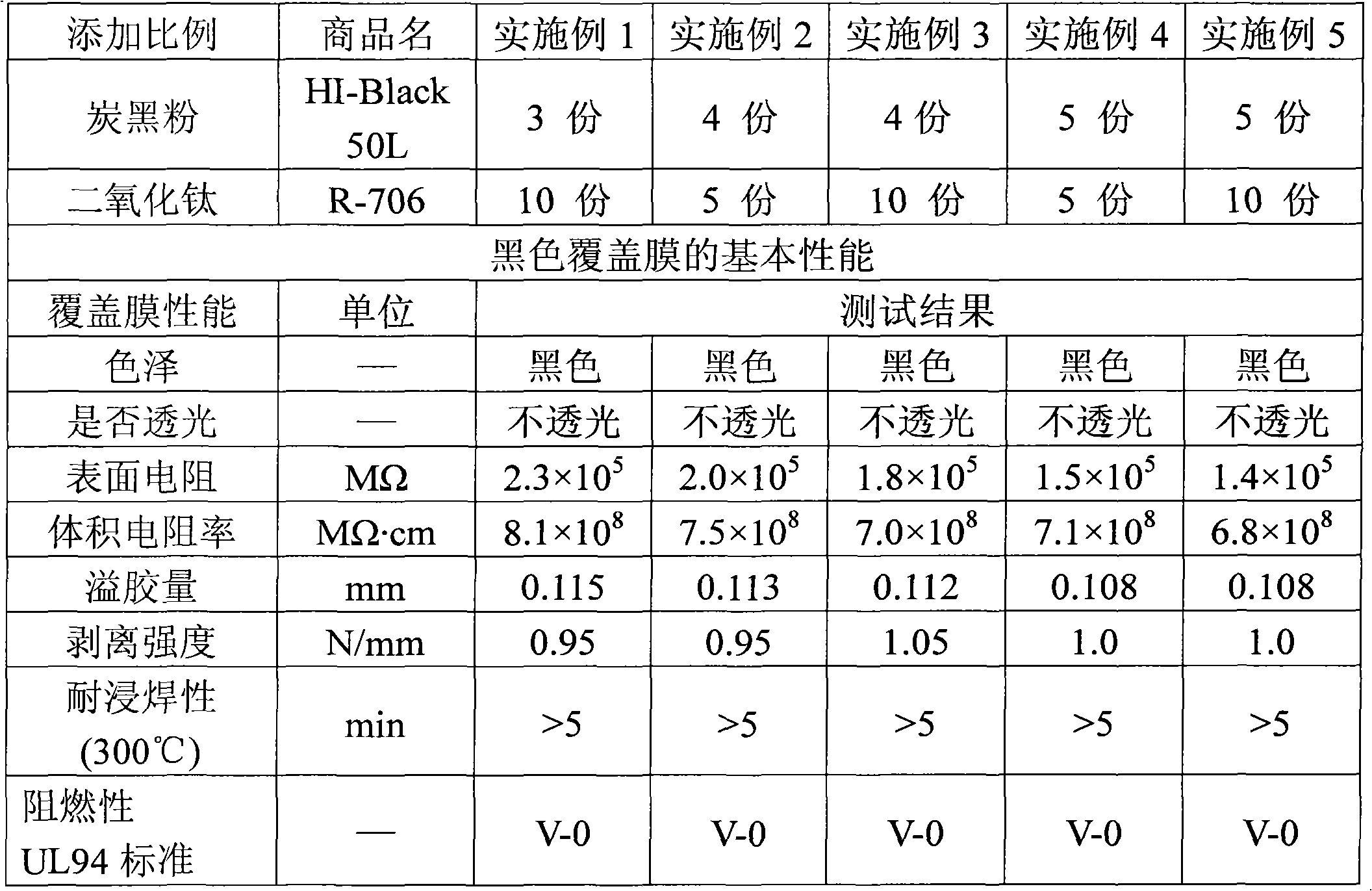

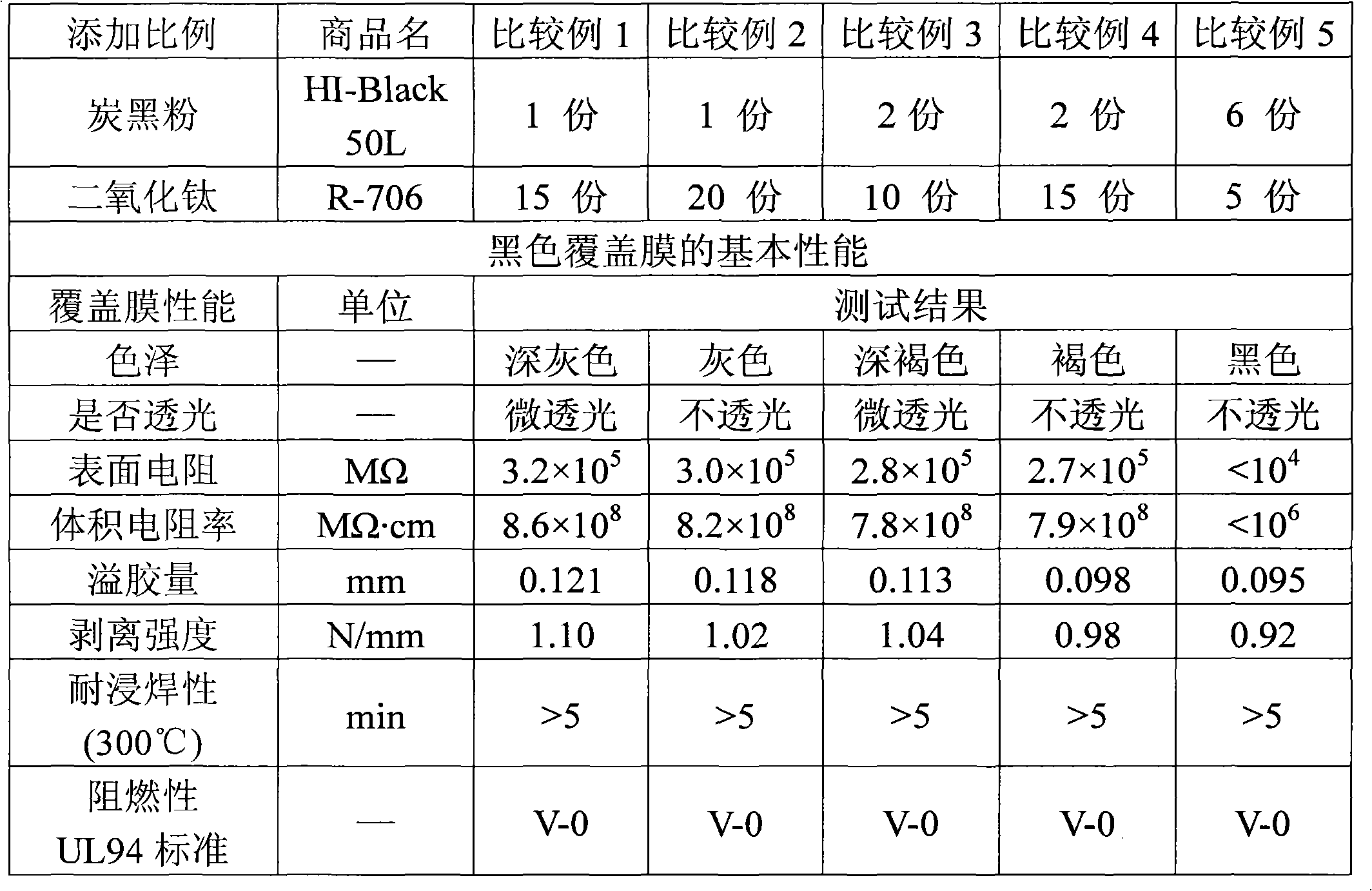

[0052] The color and light transm...

Embodiment 1

[0055] Epoxy resin (product model NC-3000-H, epoxy equivalent 290 g / eq, manufactured by Nippon Kayaku) 35 parts by weight; carboxyl-terminated nitrile rubber (product model Nipol 1072CG, acrylonitrile content 27% by mass, manufactured by Zeon Corporation) 21 parts by weight; 9.1 parts by weight of acrylate-modified epoxy resin (product model BPF307, elastomer content 20% by mass, manufactured by Nippon Shokubai Co., Ltd.); 6.63 parts by weight of diaminodiphenyl sulfone (DDS); 1-cyanoethyl -0.163 parts by weight of 2-ethyl-4-methylimidazole (2E4MZ-CN); 1.95 parts by weight of carbon black powder (commodity model HI-Black 50L, manufactured by Korea KCB); titanium dioxide (commercial model R-706, manufactured by DuPont) 6.5 parts by weight; phosphorus-containing flame retardant (product model OP-935, manufactured by Clariant, Germany) 13 parts by weight; antioxidant (product model 1010, manufactured by CIBA GEIGY Co.) 0.05 parts by weight. A butanone solvent was used to adjust t...

Embodiment 2

[0056] Example 2: The solids content of the benchmark formula is calculated as 100 parts by weight, except for carbon black powder and titanium dioxide, other components are added in the same proportion. Add 4.0 parts of carbon black powder and 5.0 parts of titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com