High-retardant polyamide

A polyamide, high flame retardant technology, applied in the field of flame retardant polyamide, can solve the problems of no test data of flame retardant effect, complicated preparation process of flame retardant, and unfavorable expansion of production, etc., so as to solve the problem of wick effect, Excellent flame retardant effect, excellent flame retardancy and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

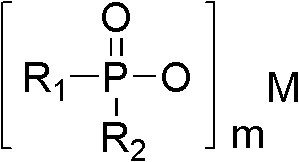

Method used

Image

Examples

Embodiment 1

[0028] First, 85 parts of polyamide 6, 14 parts of monoisobutylaluminum phosphinate, and 1 part of boehmite were dried at 100°C for 8 hours under vacuum, then pre-mixed and melted at 230°C in a twin-screw extruder Blending, extruding, granulating, and drying to obtain highly flame-retardant polyamide.

[0029] The oxygen index of the highly flame-retardant polyamide is 27.3%, the UL-94 vertical burning rating of the 1.6 mm thick sample is V-0, and the 0.8 mm thick sample UL-94 vertical burning rating is NR.

Embodiment 2

[0031] First, 84 parts of polyamide 6, 10 parts of aluminum monoisobutylphosphinate, 5 parts of melamine pyrophosphate, and 1 part of boehmite were dried at 100°C for 8 hours under vacuum, and then pre-mixed evenly and extruded by twin-screw. Melt and blend at 230°C in the discharge machine, extrude, granulate, and dry to obtain high flame-retardant polyamide.

[0032]The oxygen index of the highly flame-retardant polyamide is 28.1%, the UL-94 vertical burning rating of the 1.6 mm thick sample is V-0, and the 0.8 mm thick sample UL-94 vertical burning rating is V-2.

Embodiment 3

[0034] Dry 74.5 parts of polyamide 6, 12 parts of aluminum diisobutylphosphinate, 3 parts of melamine polyphosphate, 0.5 parts of boehmite, and 10 parts of alkali-free glass fiber at 100°C for 8 hours under vacuum, and then pre- After mixing evenly, melt and blend in a twin-screw extruder at 245°C, extrude, granulate, and dry to obtain a highly flame-retardant polyamide.

[0035] The oxygen index of the highly flame-retardant polyamide is 30.4%, the UL-94 vertical burning rating of the 1.6 mm thick sample is V-0, and the 0.8 mm thick sample UL-94 vertical burning rating is V-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com