Halogen-free expansion-type flame retardant for polyethylene and preparation method thereof

An intumescent flame retardant and flame retardant technology, which is applied in the field of polymer compounding, can solve the problems of limited application, large amount of flame retardant added, and decreased mechanical properties of materials, so as to achieve the goal of expanding the scope of use and good flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

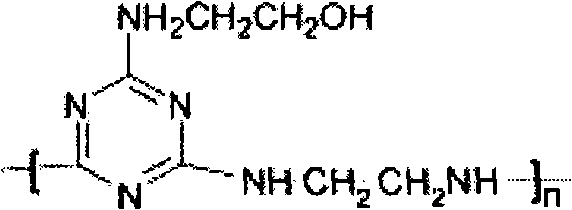

[0022] This example describes a method for preparing a macromolecular triazine derivative hydroxyalkylaminodiamine triazine oligomer. The molecular structural formula of the prepared hydroxyalkylaminodiaminetriazine oligomer is as follows:

[0023]

[0024] In the formula, n is 20-200.

[0025] Preparation : Add 46.1g of cyanuric chloride and 20mL of acetone in a 500mL reaction flask equipped with a reflux condenser, a constant pressure dropping funnel, a stirrer and a thermometer, and stir fully to make the cyanuric chloride disperse evenly. At 5°C, add 22.25g propanolamine and NaOH solution (10g NaOH dissolved in 25mL distilled water) dropwise evenly while stirring, and react at -5-5°C for 1-3 hours after the addition is complete. Then raise the temperature to room temperature, then evenly add 29g hexamethylenediamine and NaOH solution (10g NaOH dissolved in 25mL distilled water) dropwise to the reaction flask, raise the reaction temperature to 40-65°C after the dropwise...

Embodiment 2~13 and comparative example 1

[0027] See Table 1. According to the addition amount listed in Table 1, the coated ammonium polyphosphate, macromolecular triazine derivatives, melamine and its derivatives, polymer / inorganic nanocomposites, flame retardant synergists, coupling agent and antioxidant, fully mixed in a high-speed mixer with a rotation speed of 5000 rpm for 20 to 40 minutes to prepare a halogen-free intumescent flame retardant for polyethylene.

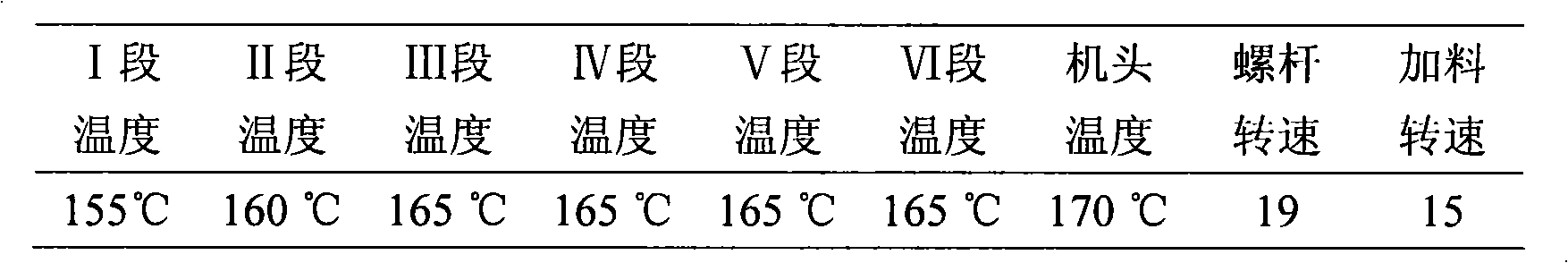

[0028] Polyethylene and the flame retardant obtained above are mixed in a ratio of 7:3 (weight ratio), extruded with an extruder, and the process of the extruder is:

[0029]

[0030] Then sample preparation by injection molding, the injection molding process is:

[0031]

[0032] Finally, a flame-retardant polyethylene material sample was obtained, and the combustion performance of the sample was tested, and the obtained results are also shown in Table 1.

[0033] Compared with Comparative Example 1, it can be seen that the flame retardant of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com