Patents

Literature

45results about How to "Guaranteed flame retardant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

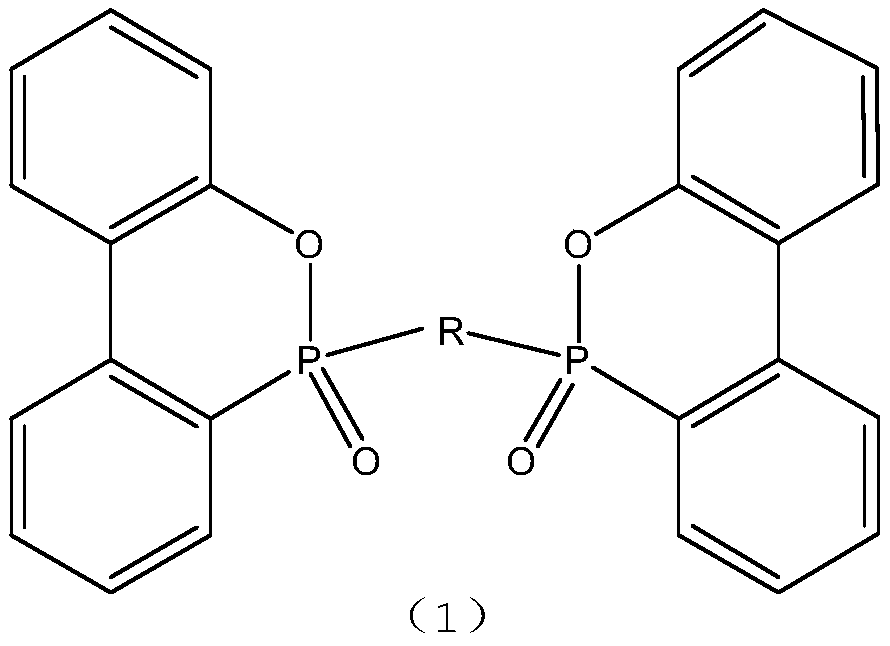

Phosphorus-containing flame retardant composition, and phosphorus-containing polyphenyl ether resin composition, prepreg and laminated board using the same

ActiveCN104774476AExcellent dielectric propertiesImprove heat resistanceSynthetic resin layered productsCircuit susbtrate materialsDielectricHalogen

The invention provides a phosphorus-containing flame retardant composition, including: a hypophosphite compound, a DOPO derivative and a polyphosphazene compound. The composition as a flame retardant can play a synergistic effect of several phosphorus-containing compounds, realizes halogen-free flame retardance under small addition amount and reaches level V-0. The invention also provides a contains a polyphenyl ether resin composition containing the above phosphorus-containing flame retardant compositions and a prepreg and a copper clad laminated board prepared from the same. After curing, the polyphenyl ether resin composition achieves flame retardance of V-0 grade under the condition to which the halogen flame retardant does not apply and keeps good dielectric property and heat resistance of polyphenyl ether resin; the prepreg and copper clad laminated board made from the composition have good dielectric property and heat resistance, and realize halogen-free flame retardance to UL 94-V0 grade while ensuring excellent heat resistance and dielectric property; and the composition is applicable to the field of high speed and high frequency printed circuit board, and is in line with the future requirements of green and environmental protection.

Owner:GUANGDONG SHENGYI SCI TECH

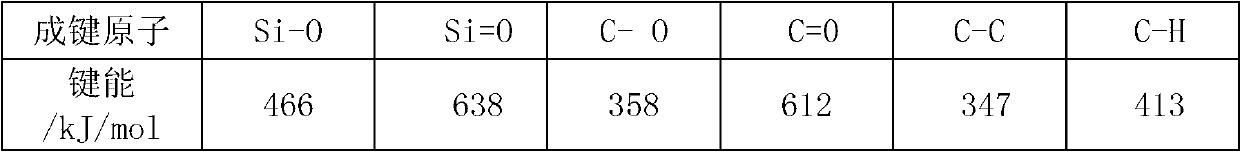

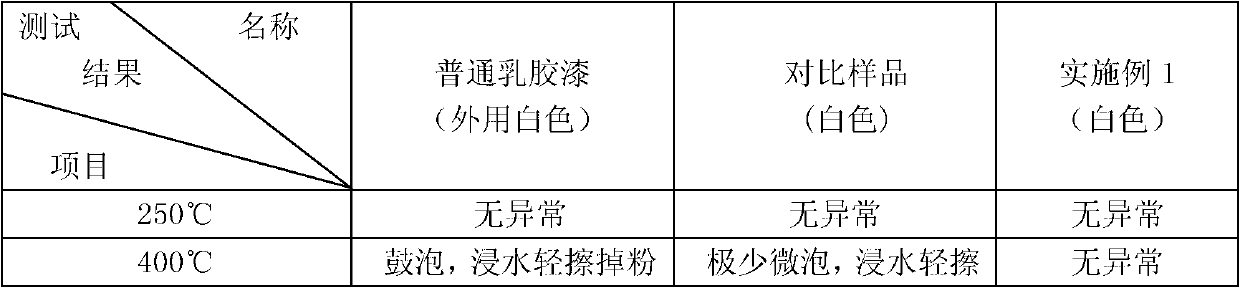

Novel mineral reflective thermal insulation coating for architecture and preparation method thereof

ActiveCN102816465AKeep low carbonGuaranteed flame retardantReflecting/signal paintsThermal insulationEmulsion

The invention relates to a novel mineral reflective thermal insulation coating for architecture and a preparation method thereof. The coating comprises, by weight, 0.1-0.6% of a thickener, 0.2-1.2% of an antifoaming agent, 0.1-0.5% of a dispersing agent, 0.5-1.0% of a stabilizer, 6.0-20.0% of functional pigments, 5.0-27.0% of fillers, 4.0-10.0% of a modified emulsion with a concentration of 46-50wt%, 15.0-23.0% of potassium silicate with a concentration of 28-32wt%, 1.0-5.0% of a water repellent agent, 6.0-10.0% of ceramic microbeads, 0-1.5% of a rheological agent and the balance water. According to the coating and the preparation method thereof, defects of latex type reflective thermal insulation coatings are overcome, national standards are accorded with, and the advantages of being energy-saving, economical, environment-friendly, low-carbon, flame retardant, high temperature resistant, good anti-aging and anti-contamination performances and the like of inorganic coatings are maintained.

Owner:PANJIN AOMA PAINT

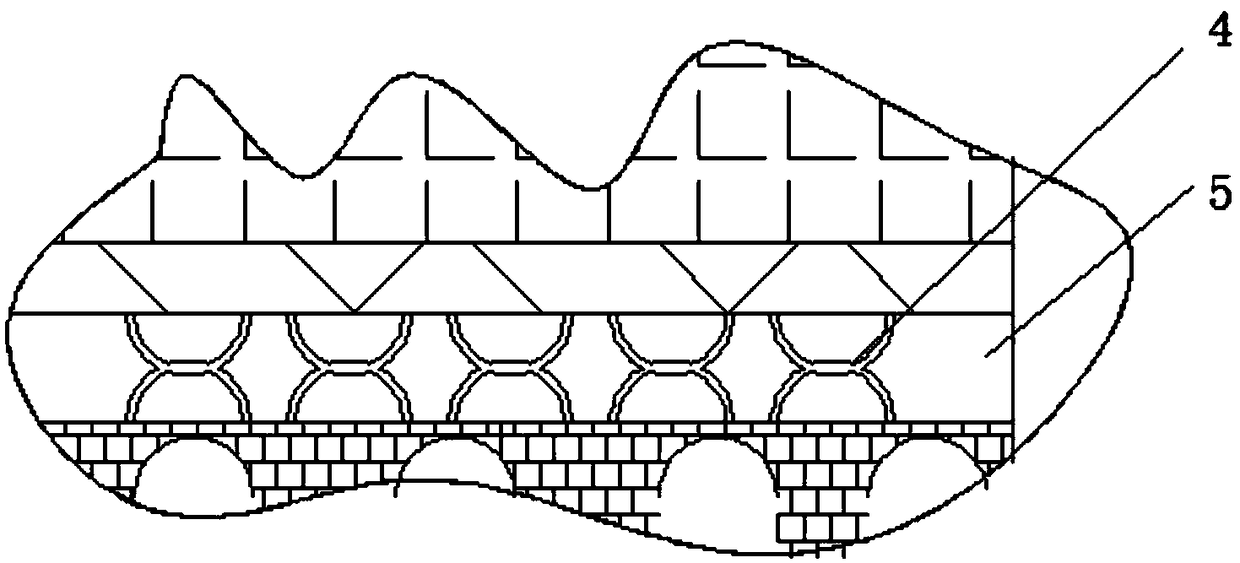

Method for preparing honeycomb enhanced phenolic foam composite materials

The invention relates to a method for preparing honeycomb enhanced phenolic foam composite materials. The method is characterized by including the steps of: (1) pouring phenolic resin foam composite into a die; (2) vertically placing a honeycomb in the phenolic resin foam composite in the die; (3) placing the die with the phenolic resin foam composite and the honeycomb in the step (2) into a baking oven at the temperature of 50-100 DEG C for foaming for 5-10h, and obtaining the honeycomb enhanced phenolic foam composite material. Via one-time soaking and heating consolidation, the method is capable of preparing the honeycomb enhanced foam composite materials with phenolic foam ingredients in the honeycomb materials and phenolic foam filled in honeycomb lattice holes, the operation procedure is extremely simple, only the die and the baking oven are utilized as equipment, so that the method has the advantages of efficiency and low cost, meanwhile, the composite material products can be guaranteed to have the advantages of good combination properties like light weight, sound insulation, heat insulation, specific strength, specific modulus, water resistance and flame retardance.

Owner:ARAMICORE COMPOSITE

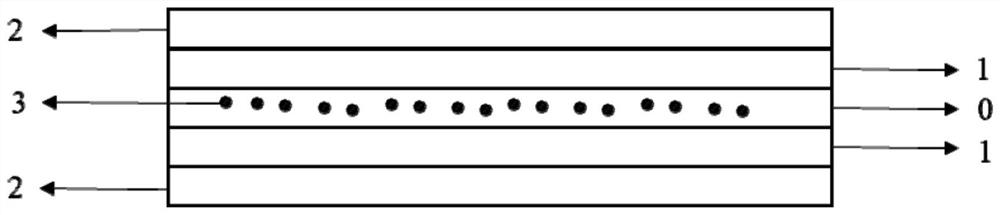

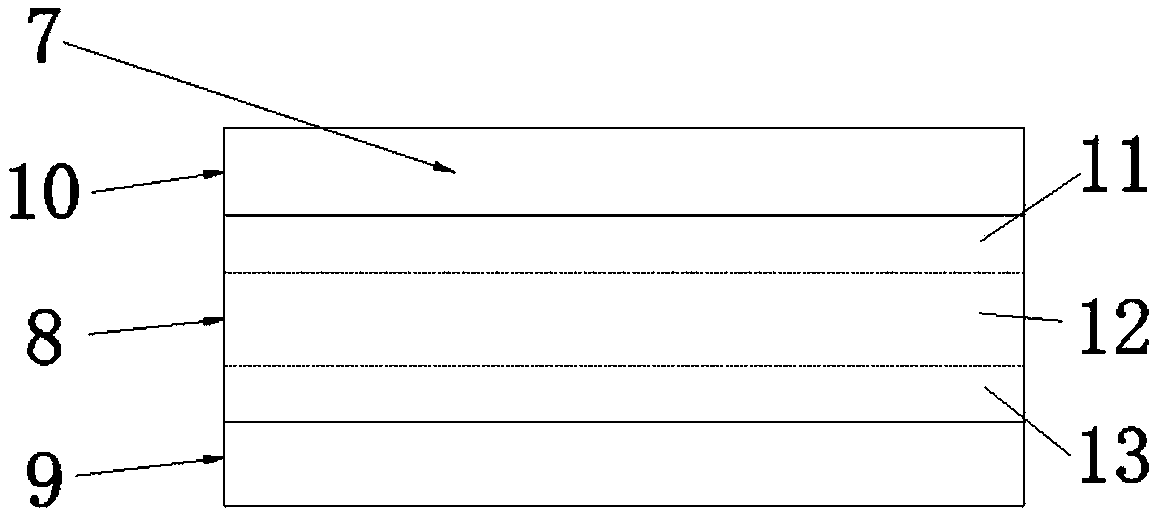

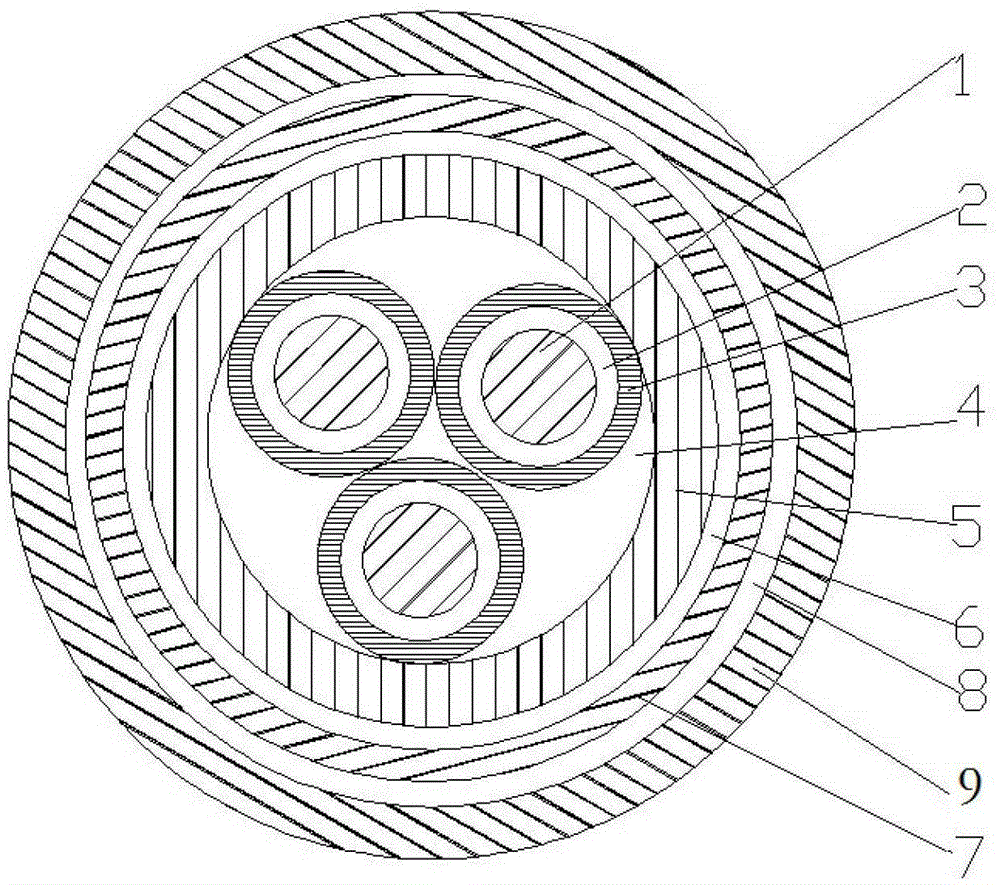

High-performance cable for construction

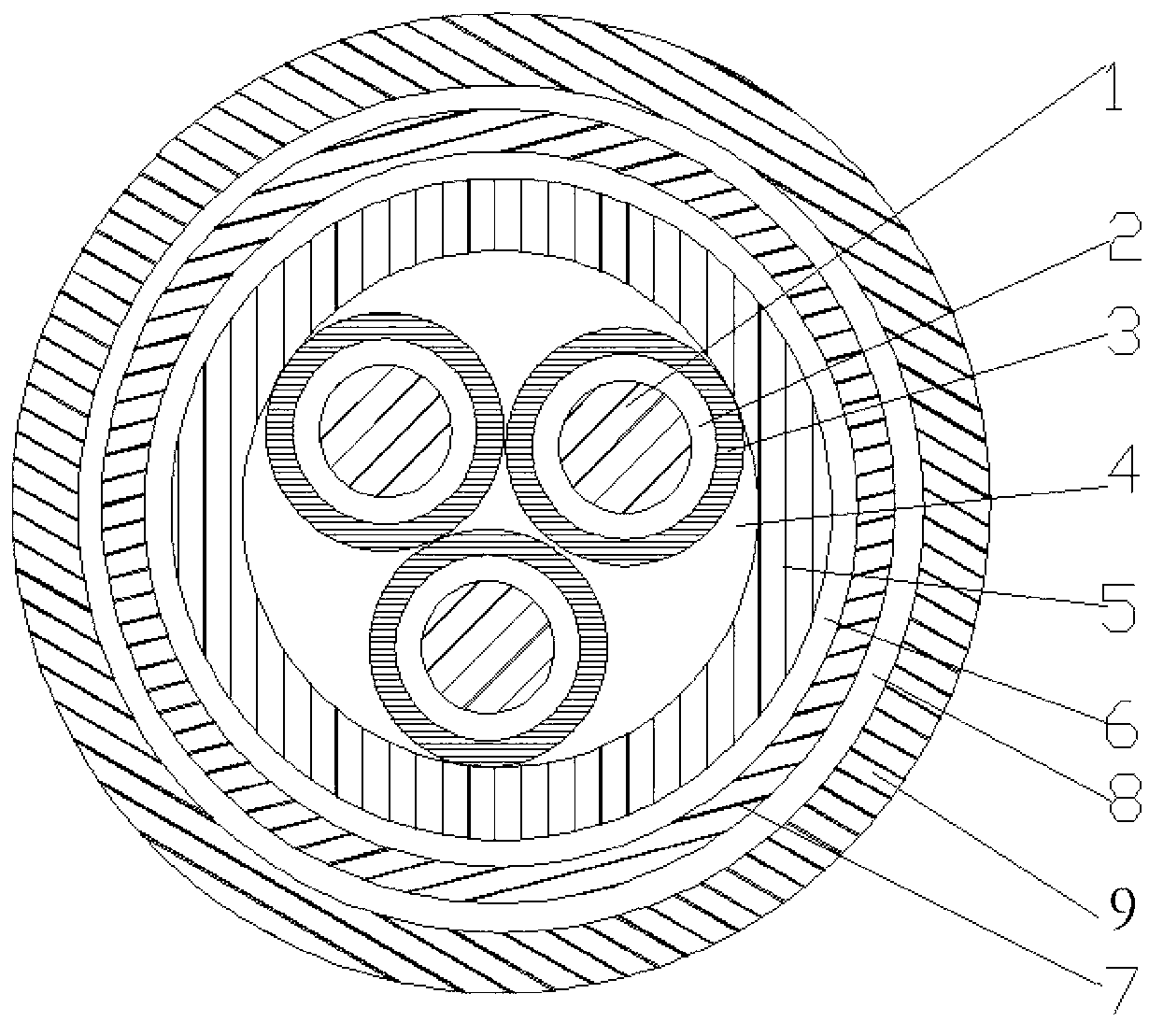

ActiveCN103310893AImprove crack resistanceImprove environmental aging resistanceInsulated cablesInsulated conductorsElectricityElectrical conductor

The invention discloses a high-performance cable for construction. The high-performance cable for construction solves the problem that the existing cable for construction is low in fire resistance, poor in weather resistance, short in service life and the like. The high-performance cable for construction has the advantages of being environmentally friendly, inflaming retarding, waterproof, moistureproof, strong in antijamming capability, excellent in electric performance, long in service life and the like. The high-performance cable for construction structurally comprises a cable core which is composed of a plurality of insulating wire cores arranged in a filling body, each insulating wire core comprises a conductor and a double-layer co-extrusion heterogeneous insulating layer arranged outside the conductor in a pressing and wrapping mode, and the cable core is sequentially wrapped by a wrapping layer, a cable shielding layer, an oxygen separating layer, an armor layer and a cable outer sheath sequentially from inside to outside.

Owner:SHANGDONG HUALING CABLE

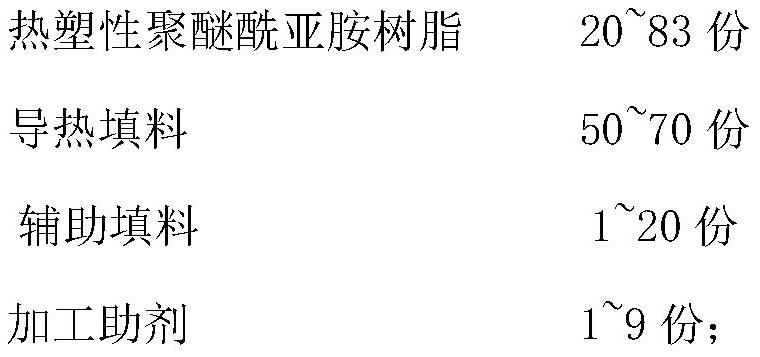

Thermoplastic polyether imide insulating heat conduction composite material and preparation method thereof

ActiveCN108250747AGuaranteed insulation performanceImprove insulation performanceImidePolyetherimide

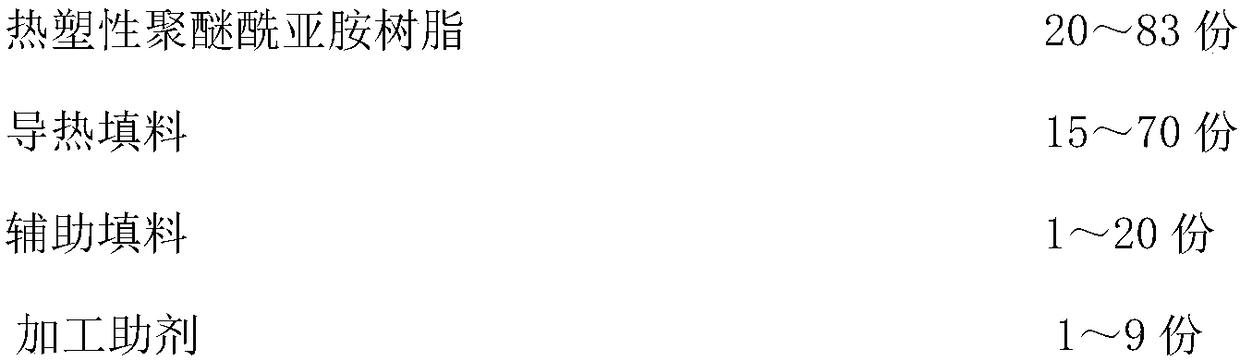

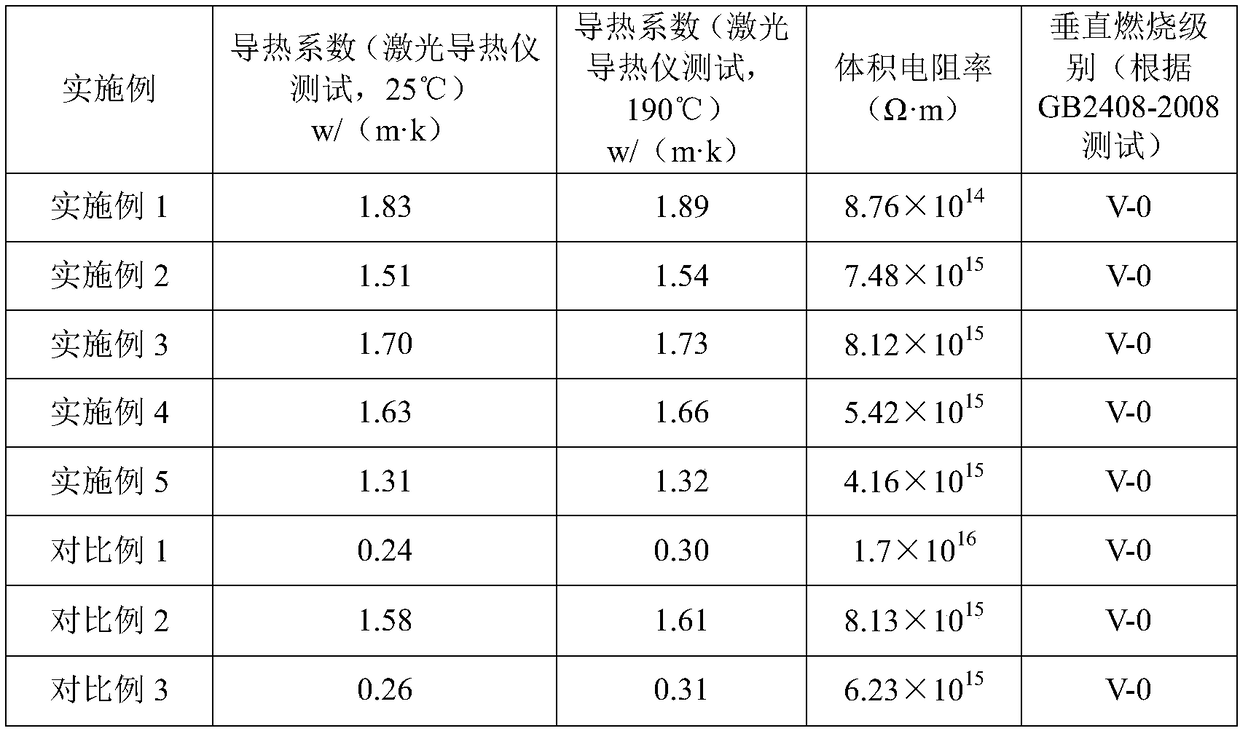

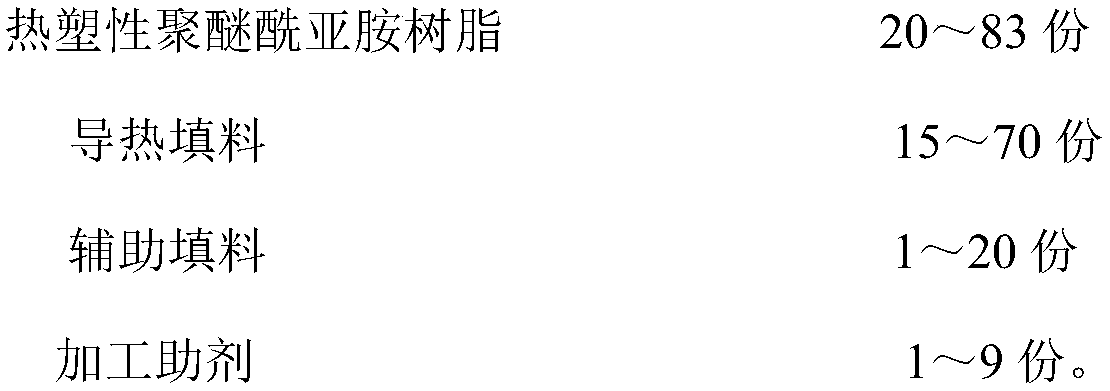

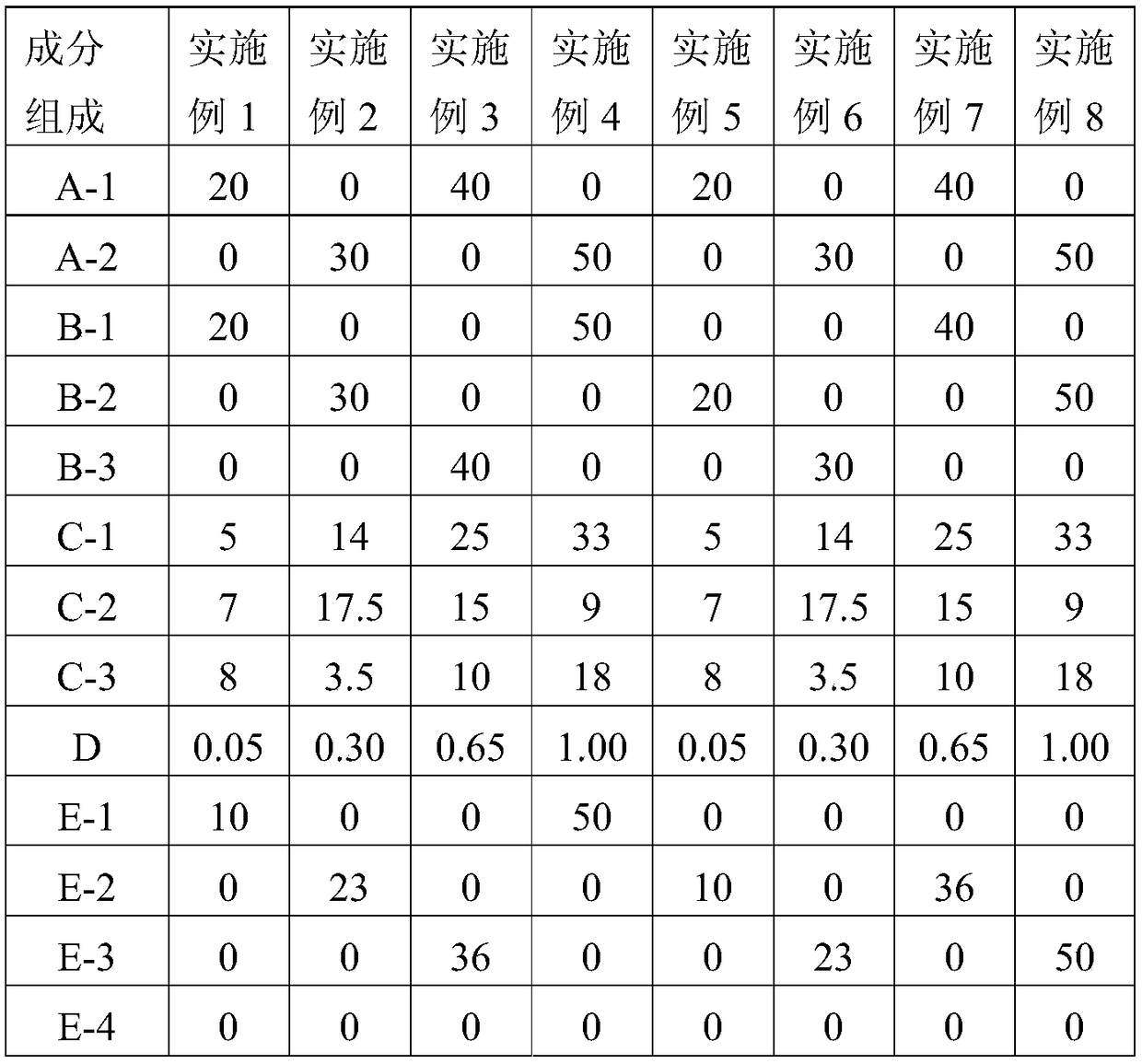

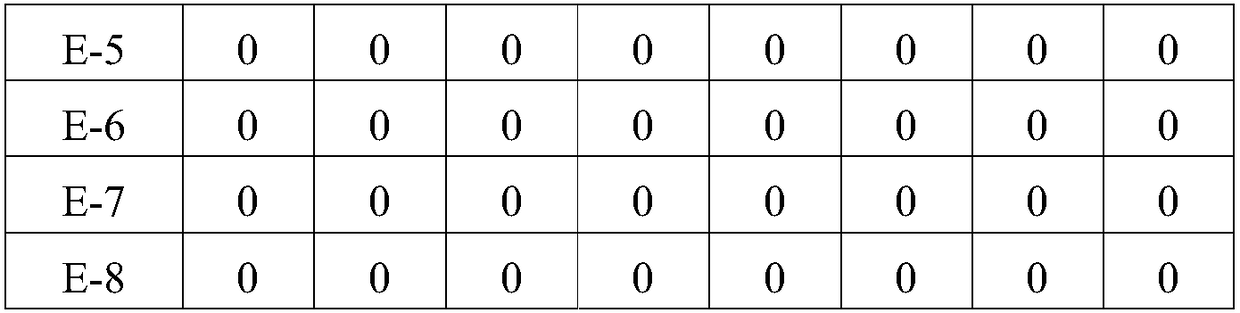

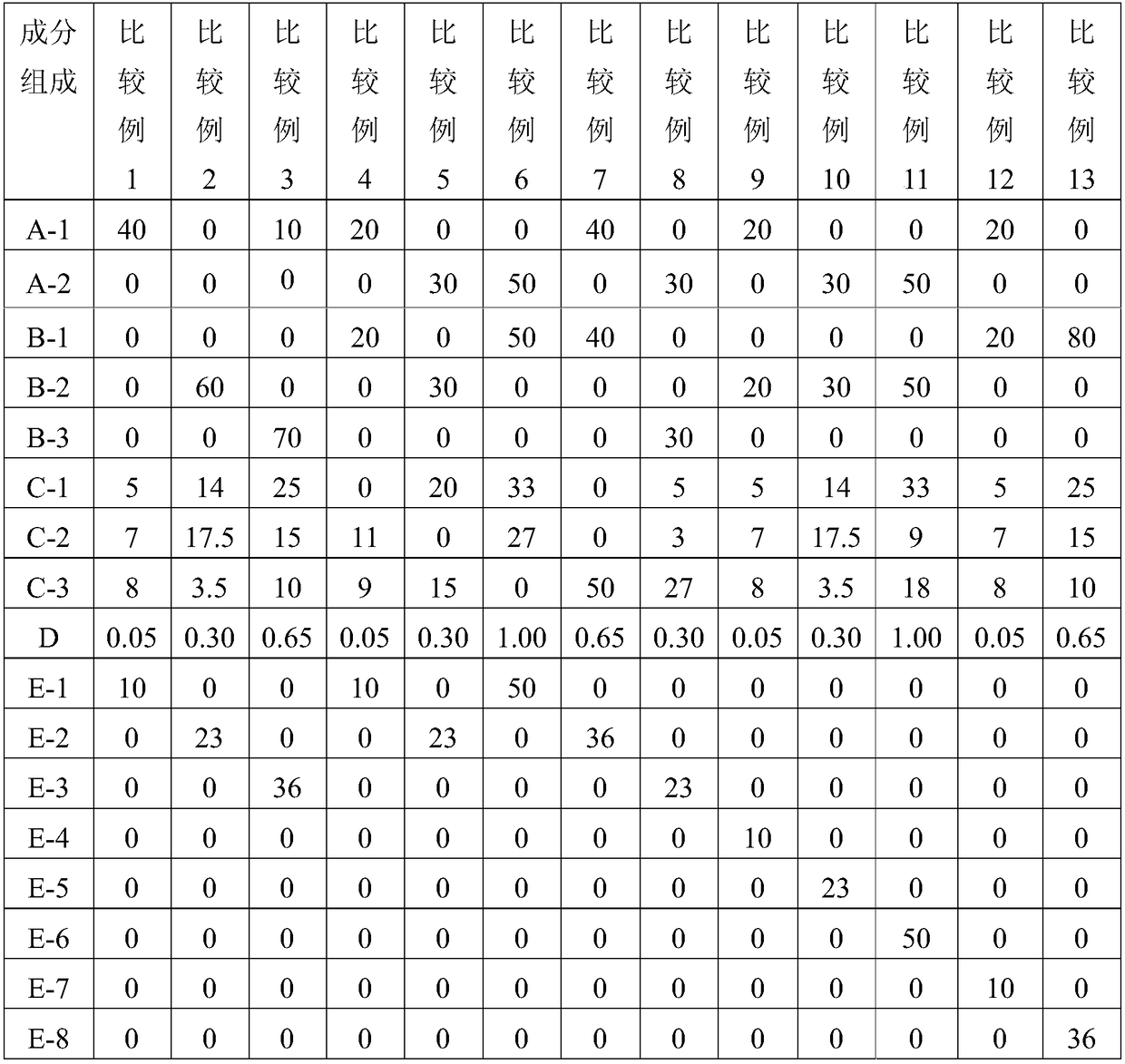

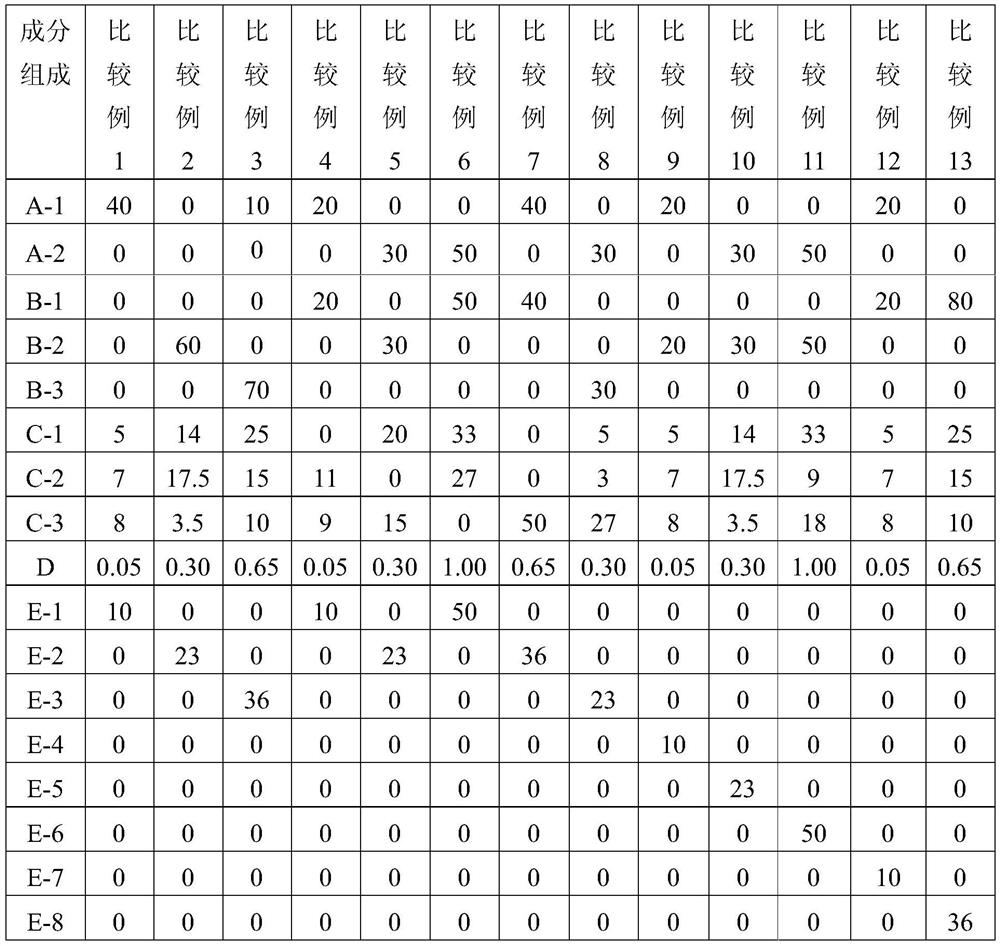

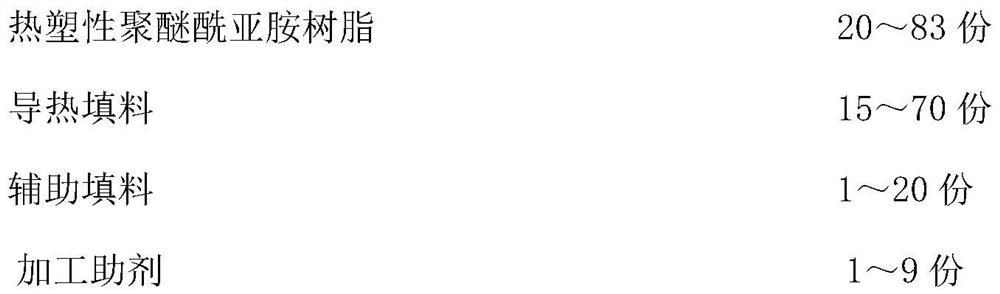

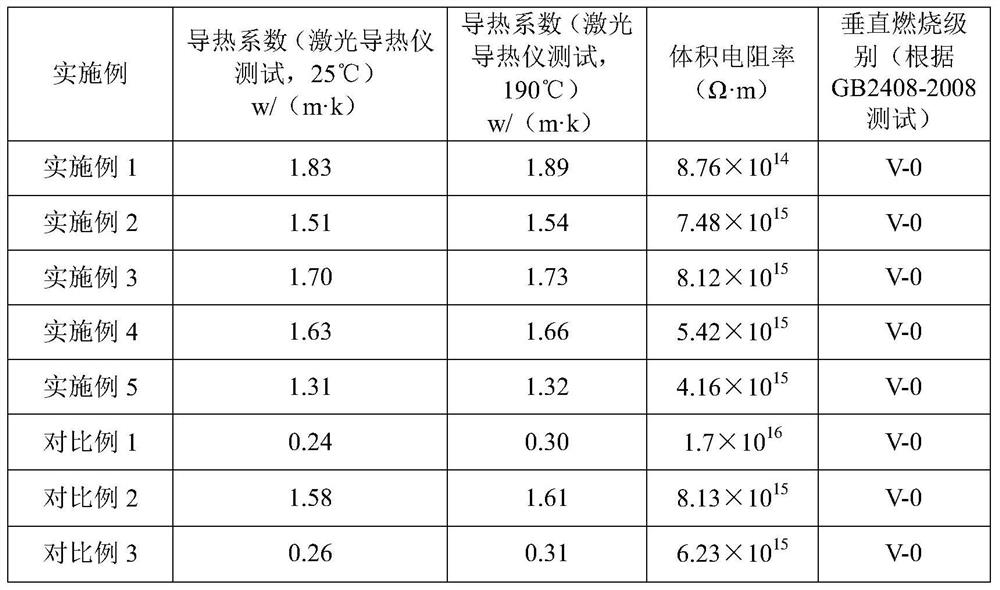

The invention discloses a thermoplastic polyether imide insulating heat conduction composite material and a preparation method thereof. The thermoplastic polyether imide insulating heat conduction composite material comprises the following components in parts by mass: 20-84 parts of a thermoplastic polyether imide resin, 15-70 parts of a heat conduction filler, 1-20 parts of an auxiliary filler and 0-9 parts of processing aids. The thermoplastic polyether imide insulating heat conduction composite material disclosed by the invention is good in heat conductivity, insulation property, high temperature resistance and good in flame retardancy, and has wide application prospects in the fields of high-end electronic devices with requirements of electric insulation, heat conduction, high temperature resistance and flame retardancy, and good use properties can be maintained within a wide range of minus 150 DEG C to 200 DEG C.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Halogen-containing and antimony-free resin composition, prepreg applying same, laminated board and printed circuit board

ActiveCN109354827AImprove heat resistanceGood solder dip resistanceSynthetic resin layered productsLaminationEpoxyDip soldering

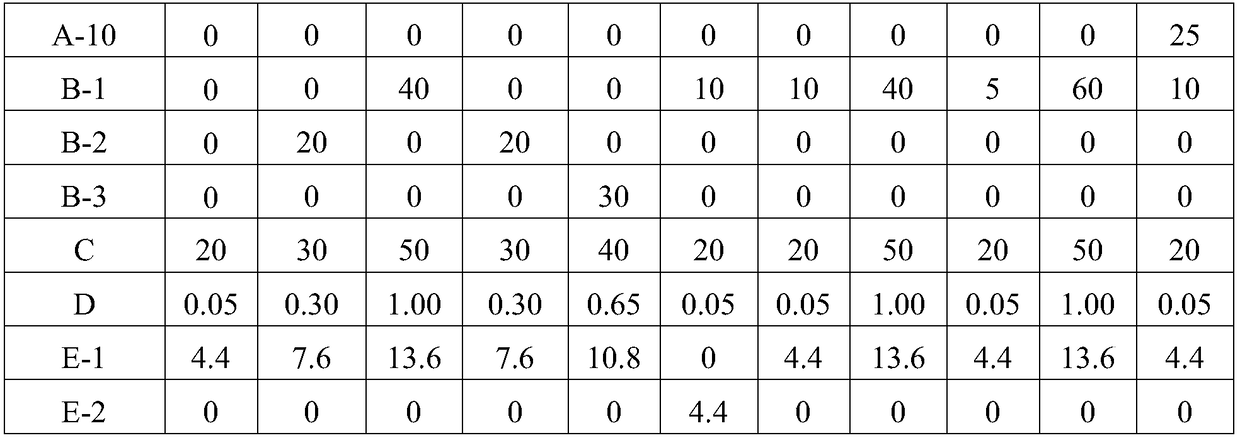

The invention provides a halogen-containing and antimony-free resin composition, a prepreg applying the same, a laminated board and a printed circuit board. The halogen-containing and antimony-free resin composition is composed of, by weight part, 20-50 parts of phosphorous-containing epoxy resin, 20-50 parts of non-frame-retardant epoxy resin, 20-60 parts of compound curing agent, 0.05-1.0 partsof curing promoter and 10-50 parts of compound filler, wherein the compound filler is the combination of phosphorous flame-retardant materials and nitrogen flame-retardant materials, and the compoundcuring agent is halogen-containing compound curing agent. The halogen-containing and antimony-free resin composition achieve phosphorous-bromine-nitrogen synergistic fire-retardant effects through thecompound filler and the compound curing agent, meet the requirements of restriction of International Environment Law on antimony compounds, and meanwhile can endow cured materials with the advantagesof good thermal resistance and dip soldering resistance, low water absorbency and the like.

Owner:SHAANXI SHENGYI TECH

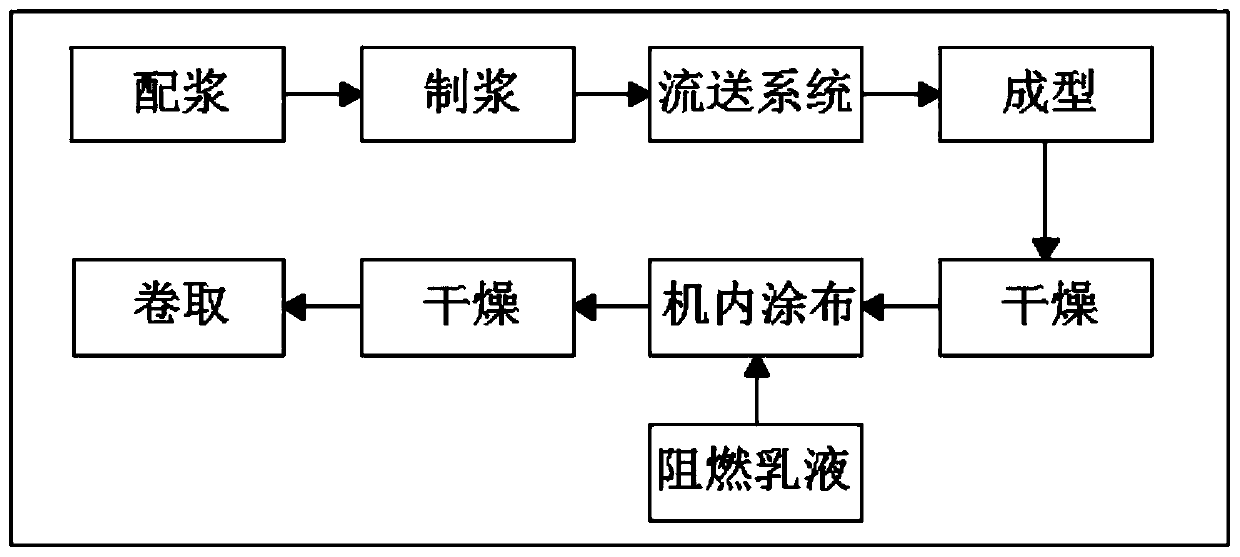

Flame-retardant and efficient air filter paper

InactiveCN111254747AImprove flame retardant performanceImprove filtering effectNatural cellulose pulp/paperWater-repelling agents additionAir filtrationPolymer science

The invention discloses flame-retardant and efficient air filter paper, which comprises a raw paper sheet, a flame retardant emulsion; wherein the flame-retardant emulsion comprises phenolic resin glue, a hydrosol film and a flame retardant; wherein the flame-retardant emulsion is coated on the surface of a raw paper sheet; the invention can provide a production mode of the flame-retardant filterpaper, has the advantages of favorable flame retardancy, excellent filter performance and environment friendliness, can continuously and effectively keep flame retardancy, is not easy to absorb moisture, and retains higher dust holding performance.

Owner:SHANDONG RENFENG SPECIAL MATERIALS

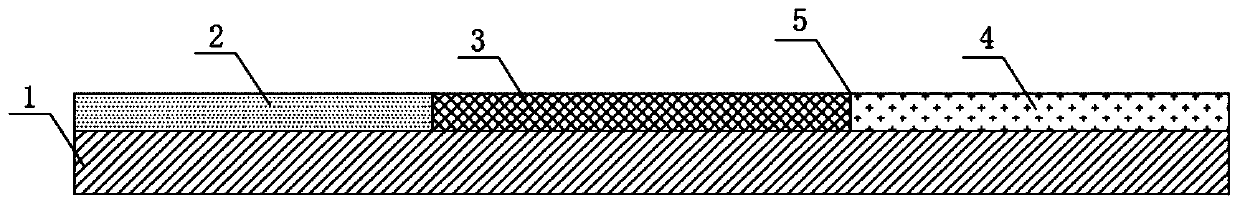

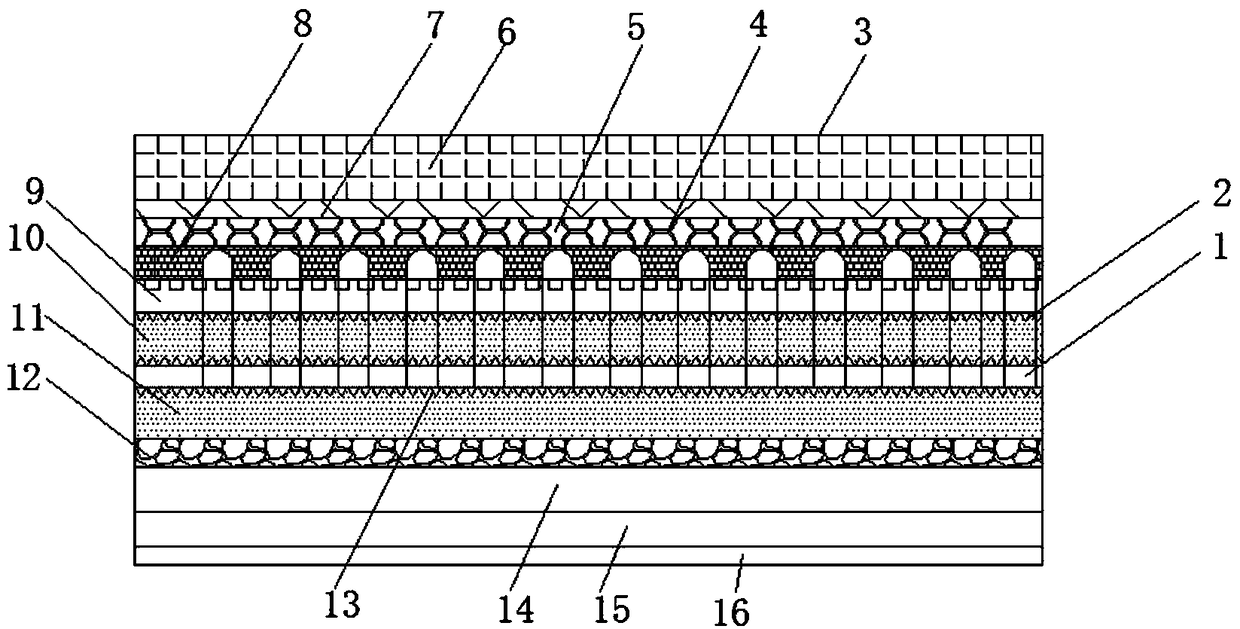

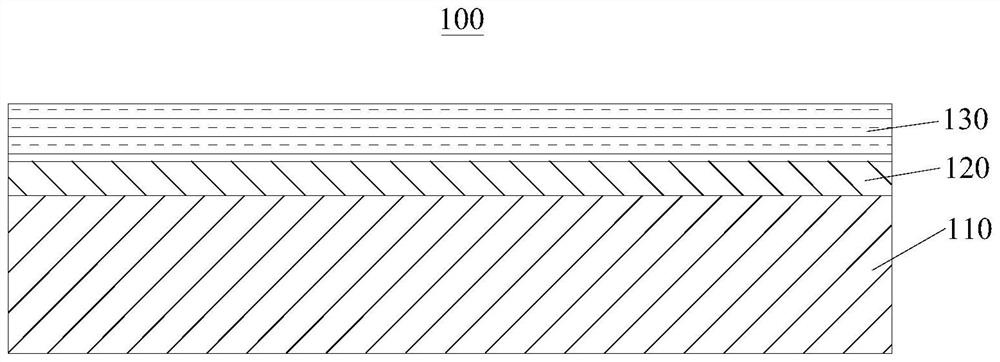

Lithium ion battery, novel current collector and preparation method of novel current collector

InactiveCN112786895AEffective thinningIncrease energy densityElectrode manufacturing processesElectrode carriers/collectorsPhysical chemistryCopper foil

The invention belongs to the related technical field of lithium ion batteries, and discloses a lithium ion battery, a novel current collector and a preparation method of the novel current collector. The novel current collector comprises a base material layer, bonding layers and a metal layer, the bonding layers are arranged on the two opposite surfaces of the base material layer respectively, the metal layer is arranged on the surfaces, far away from the base material layer, of the bonding layers, and a flame retardant is arranged in the base material layer. Therefore, the commercial copper foil or aluminum foil can be effectively thinned by the polymer base material layer, so that the energy density of the battery is improved, flame retardance can be ensured after the battery is burnt by using the flame retardant, and hidden dangers are reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

High-strength industrial filter cloth and preparation method thereof

The invention discloses a high-strength industrial filter cloth and a preparation method thereof. The high-strength industrial filter cloth comprises, by weight, 30 to 40 parts of polyphenylene sulfide yarn, 5 to 10 parts of HDPE, 10 to 20 parts of nylon resin, 4 to 6 parts of polydimethylsiloxane, 0.3 to 0.6 part of carbon black and 6 to 10 parts of BuGong tea saponin. The invention has the following beneficial effects: the polyphenylene sulfide yarn and the nylon resin are used as base materials for preparation of the filter cloth, so the filter cloth has the advantages of high mechanical strength, high temperature resistance, resistance to chemicals, flame retardancy, good thermal stability, excellent electrical performance, etc.; meanwhile, the BuGong tea saponin is used as an additive, so the industrial filter cloth has greatly improved water-absorbing quality, luster and hand feeling.

Owner:铜陵华洋特种线材有限责任公司

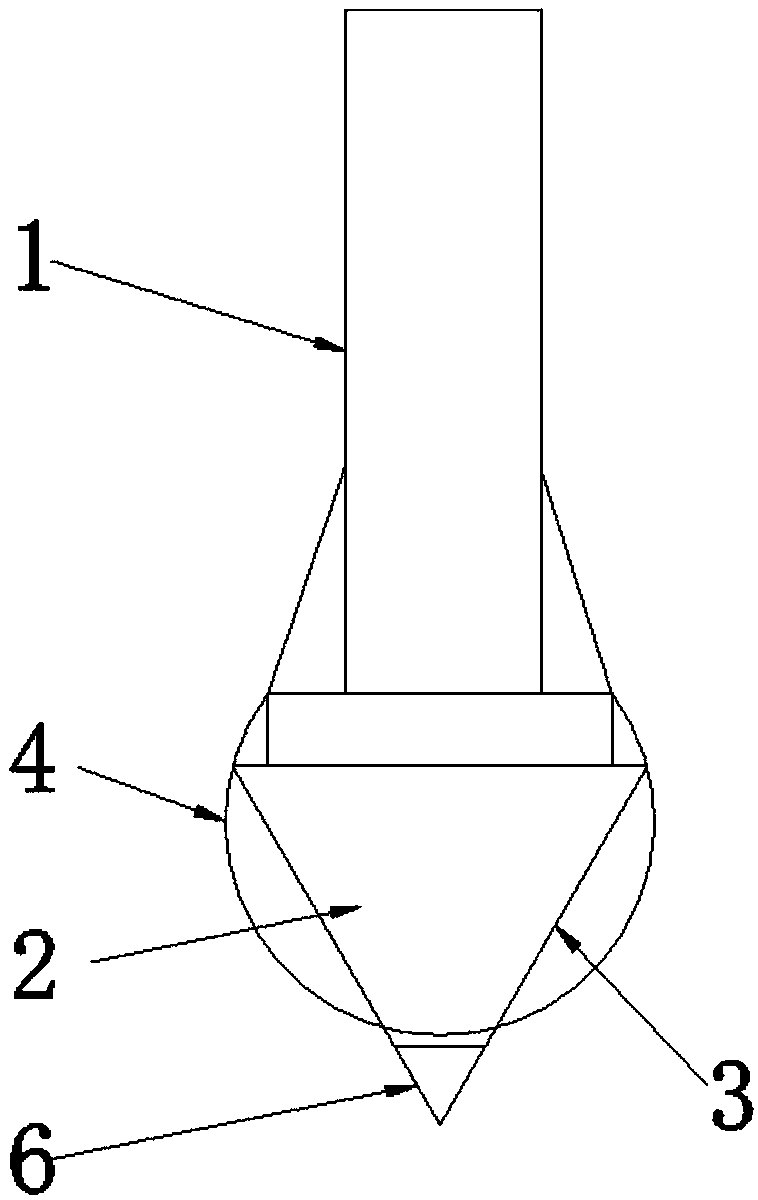

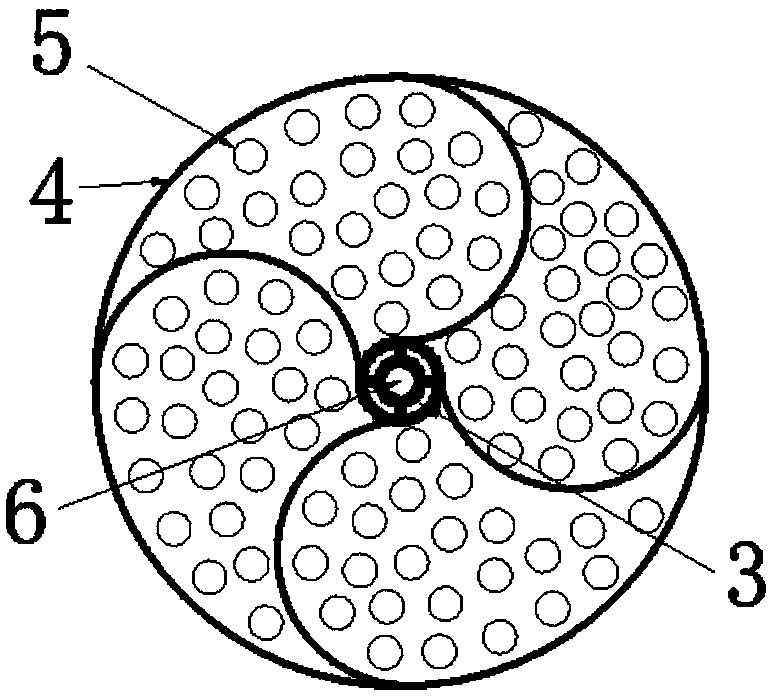

Marine oil field drill head

ActiveCN108035681AEnsure Adaptive LifeNot easy to wearFireproof paintsEarth drilling toolsWell drillingOil field

The invention discloses a marine oil filed drill head. The marine oil filed drill head mainly comprises a connecting rod and a drill body, the top of the drill body is fixedly connected with a base plate of the connecting rod, the drill body comprises a drill head body and multiple auxiliary drills, the auxiliary rods are arranged on the substrate end face of the drill head body, the drill head body is conical, grinding particles are uniformly fixed to the auxiliary rods, a water opening is formed between two adjacent auxiliary rods and is in a streamline shape, the auxiliary rods are enclosedin an arc shape with the drill head body being the center axis, the bottom of the auxiliary drill is slightly lower than the bottom of the drill head body, and a hard alloy layer is fixed to the bottom of the drill head body. The marine oil filed drill head is simple in structure, practical, safe and convenient to use, the diving efficiency of well drilling can be effectively ensured, the adapting service life of the drill body is also ensured, the drill head body is utilized to lead drilling with the point, then the auxiliary drills are utilized to conduct drilling with the surface, it is ensured that a rock stratum can be firstly cracked under the leading effect of the drill head, through whole surface drilling of the auxiliary drills, the practical effect can be ensured, and the practicability is ensured.

Owner:河北锐石钻头制造有限公司

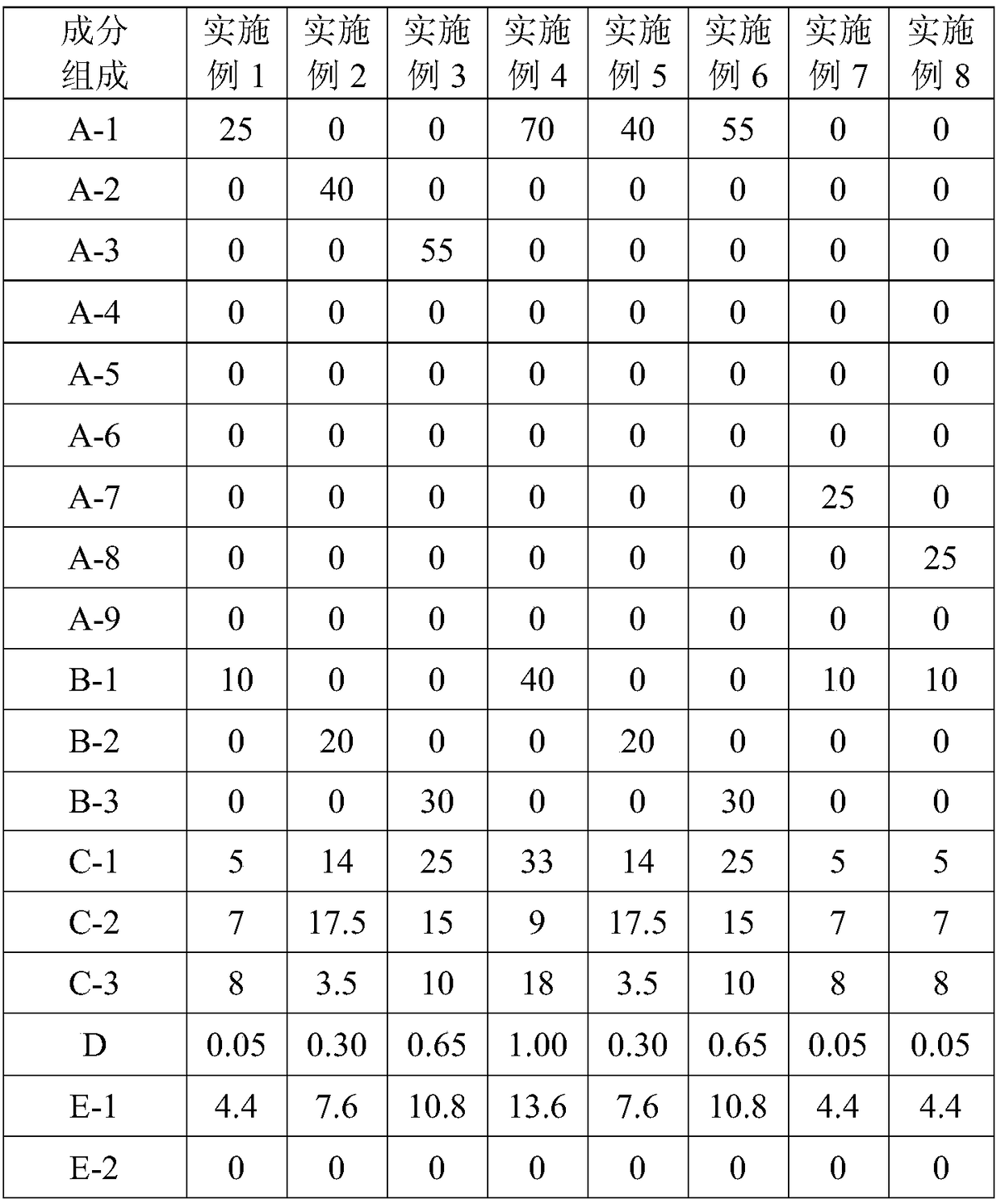

Halogen antimony-free resin composition, as well as prepreg, laminate and printed circuit board using same

ActiveCN109233209AAchieve synergistic flame retardant effectImprove flame retardant performanceEpoxyHalogen

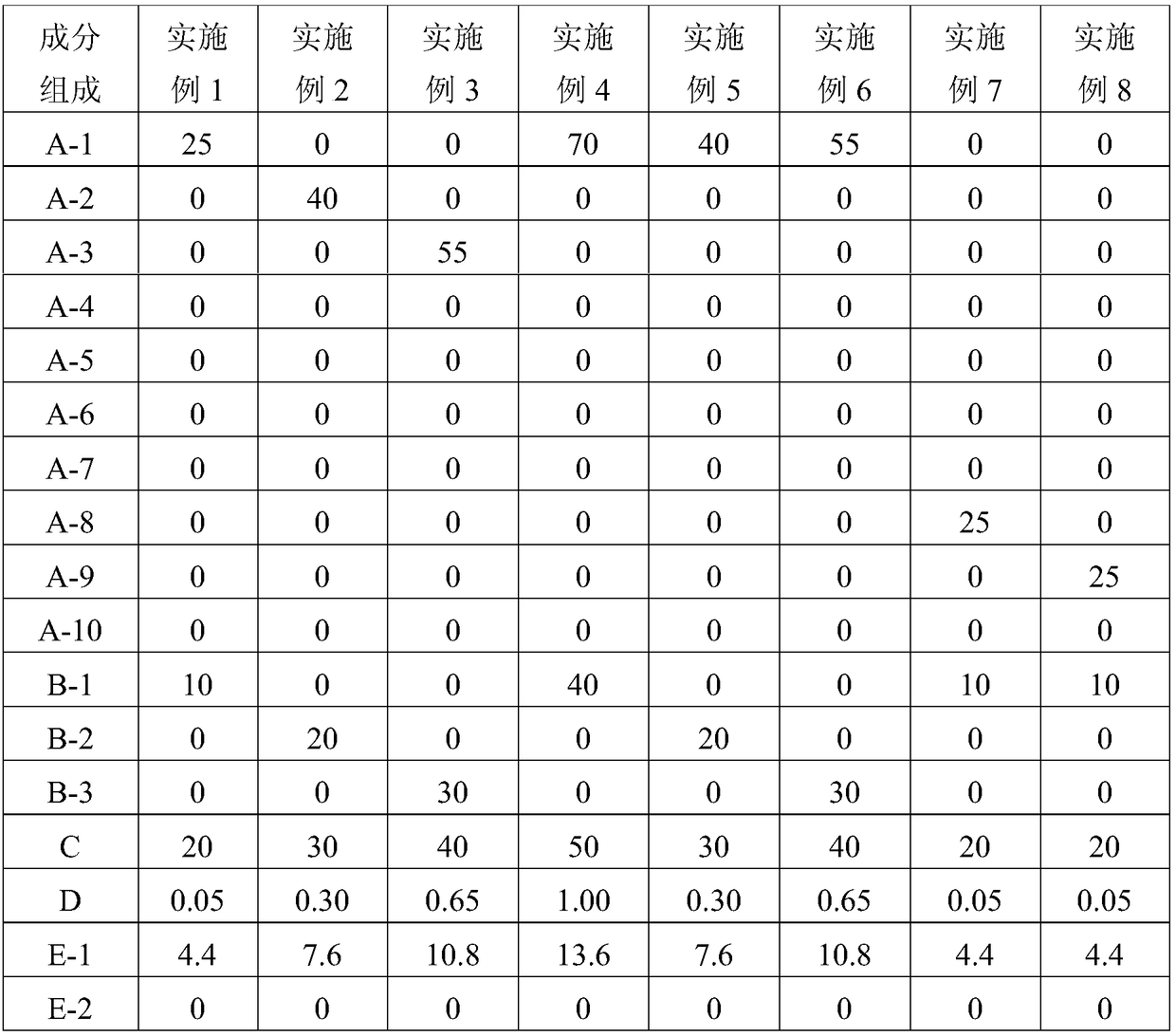

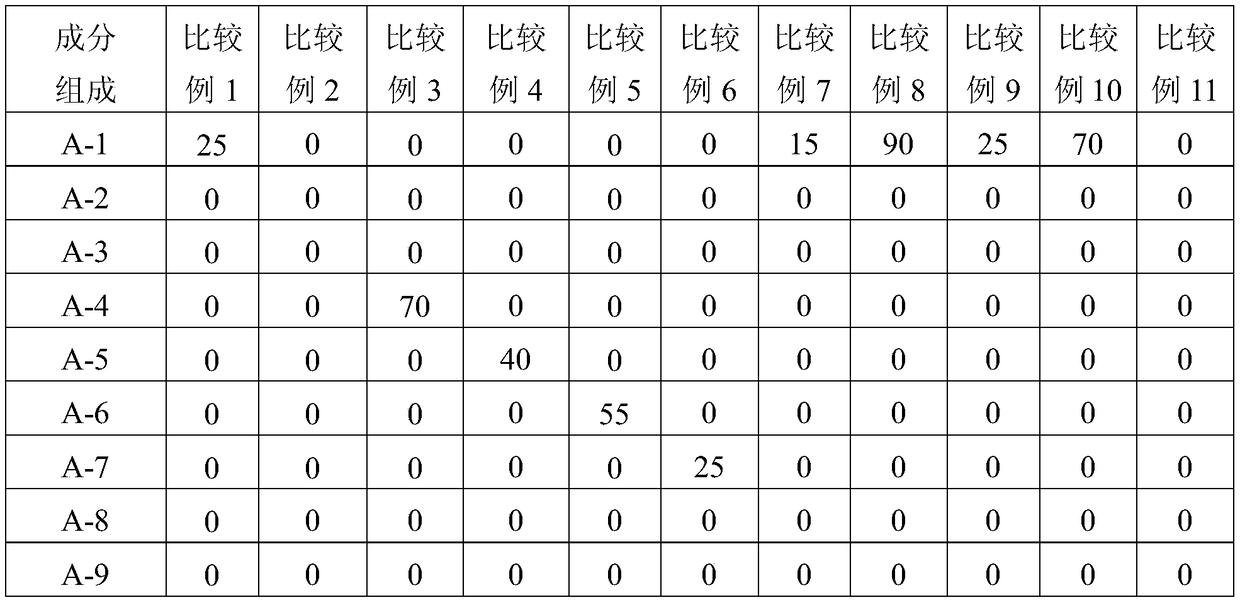

The invention provides a halogen antimony-free resin composition, as well as prepreg, laminate and printed circuit board using the same. The halogen antimony-free resin composition is prepared from the following components in parts by weight: 25-70 parts of flame-retardant epoxy resin, 10-40 parts of non-flame-retardant epoxy resin, 20-60 parts of a compound curing agent and 0.05-1.0 part of a curing accelerant, wherein the flame-retardant epoxy resin is a composition comprising phosphorus containing epoxy resin, brominated epoxy resin and nitrogen containing epoxy resin. The compound curing agent is further compounded by combining the flame-retardant epoxy resin and non-flame-retardant epoxy resin, so that the phosphorus-bromine-nitrogen synergistic flame-retardant effect can be achieved;and excellent flame retardance is given to a CEM-1 copper cladded laminate, and the technical bottleneck that the halogen antimony synergistic flame-retardant system in a traditional halogen CEM-1 copper cladded laminate cannot be substituted is broken through. The halogen antimony-free resin composition has comprehensive performance advantages of high heat resistance, high damp-heat resistance,low water absorption rate and the like.

Owner:SHAANXI SHENGYI TECH

Stable anticorrosion floor and preparing method thereof

InactiveCN105482313AImprove heat stabilityPlay a barrier roleFlooringPolyvinyl chlorideAzodicarbonamide

The invention discloses a stable anticorrosion floor. The stable anticorrosion floor is prepared from, by weight, 10-12 parts of di-iso-decylphthalate, 17-20 parts of zirconium oxychloride octahydrate, 10-15 parts of hydrochloric acid of 40%-47%, 90-100 parts of phosphoric acid of 80%-85%, 3-4 parts of tetrakis(hydroxymethyl)phosphonium sulfate, 4-7 parts of a methylamine water solution of 25%-30%, 5-7 parts of trifluoroethyl methacrylate, 0.2-0.4 part of 2-octyl-2H-isothiazol-3-one, 0.06-0.1 part of ammonium persulfate, 0.01-0.02 part of divinyl benzene, 1-2 parts of azodicarbonamide, 130-200 parts of polyvinyl chloride, 1-2 parts of pyrithione zinc, 2-3 parts of hydroxy stearic acid, 0.8-1 part of triton(r)x-100,hydrogenated, 3-5 parts of calcium aluminate and 4-6 parts of palm wax. According to the stable anticorrosion floor, due to the added pyrithione zinc and the like, the heat resistant stability of a finished product can be effectively improved, and the stable anticorrosion floor is suitable for high-temperature regions, long in service life and good in stability.

Owner:CHUZHOU YONGTONG TRAFFIC EQUIP

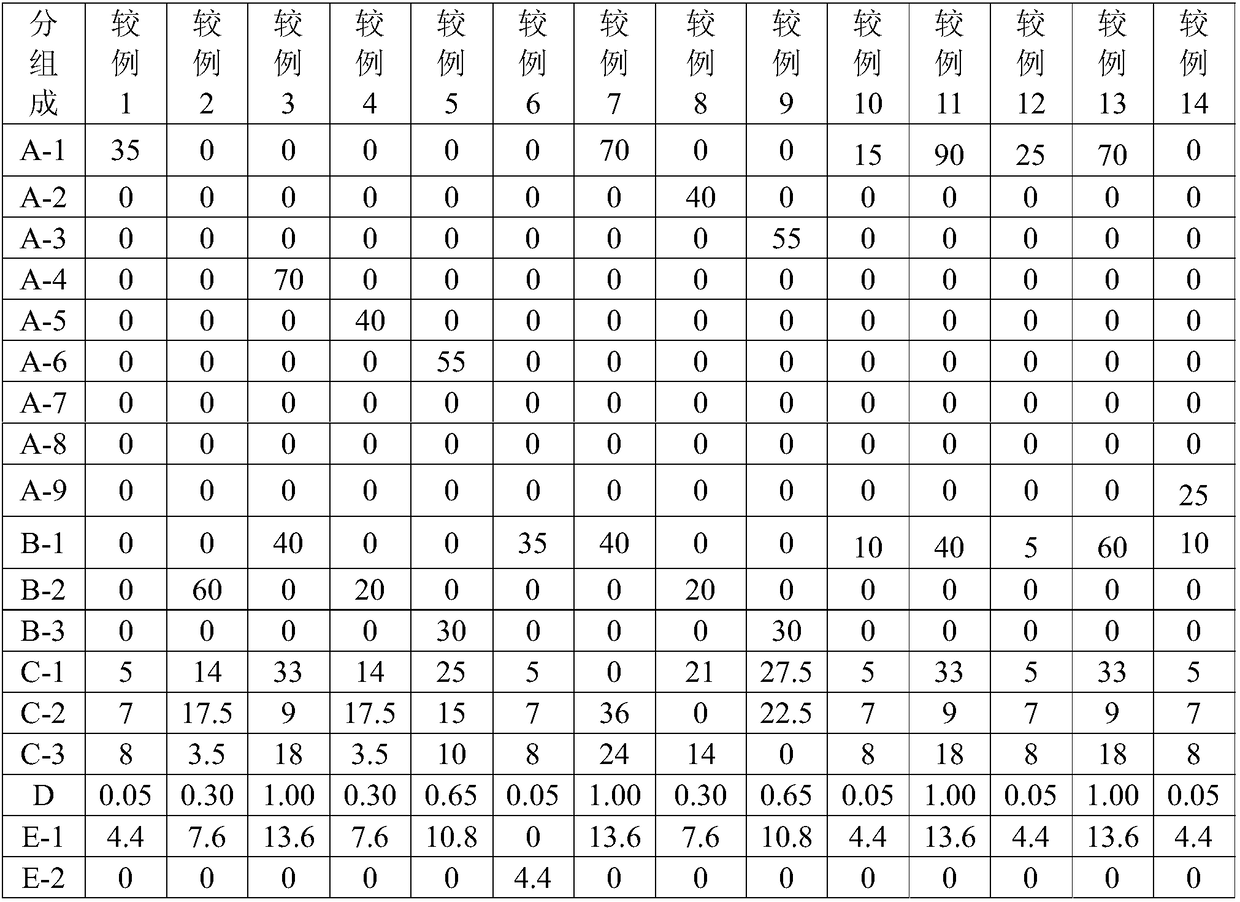

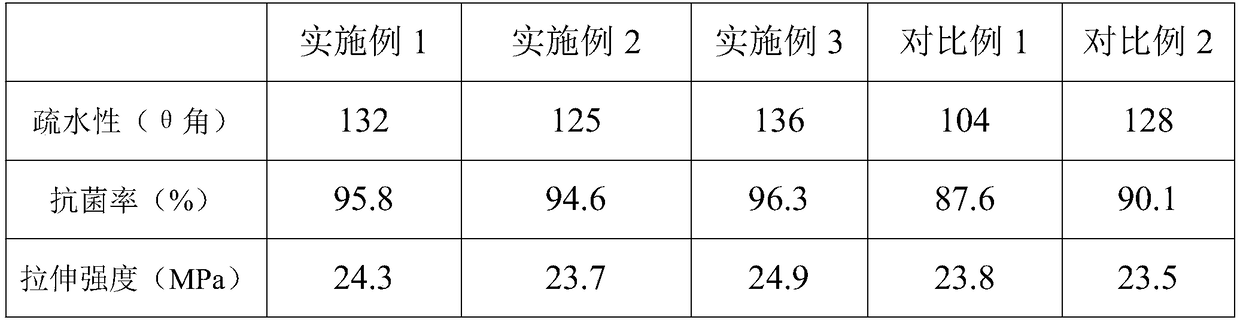

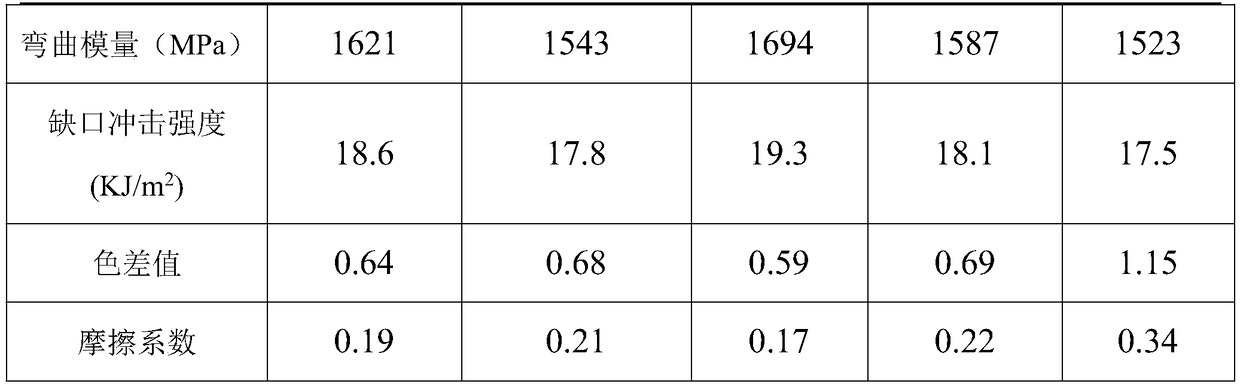

Flame-retardant PP (polypropylene) composite material and preparation method thereof

InactiveCN109337207AGood antibacterial and antifungal effectImprove self-cleaning abilityPhosphomolybdic acidPolypropylene

The invention provides a flame-retardant PP (polypropylene) composite material and a preparation method thereof. The flame-retardant PP composite material comprises components as follows: 55-65 partsof PP resin, 15-25 parts of wollastonite, 5-10 parts of magnesium-aluminum hydrotalcite, 1-3 parts of phosphomolybdic acid, 3-6 parts of modified nano-zinc oxide, 5-10 parts of silicon rubber, 1-3 parts of a titanate coupling agent, 5-10 parts of a flexibilizer, 0.2-0.8 parts of an antioxidant and 0.5-1.5 parts of polyethylene wax. The preparation method comprises steps as follows: 1), firstly, wollastonite, the silicon rubber, the titanate coupling agent, the PP resin accounting for 30%-40% of total mass and the flexibilizer accounting for 10%-20% of total mass are mixed uniformly, and masterbatches are prepared by an internal mixer; 2), the masterbatches obtained in step 1) are mixed with magnesium-aluminum hydrotalcite, phosphomolybdic acid, modified nano-zinc oxide, the antioxidant, polyethylene wax, the remaining flexibilizer and the remaining PP resin, and a mixture is subjected to melt mixing and dispersing at 210-240 DEG C in a twin-screw extruder and subjected to extruded granulation. The composite material has good hydrophobic property, friction resistance and flame retardant performance.

Owner:安庆市泽烨新材料技术推广服务有限公司

Ultrathin EMI electromagnetic shielding adhesive tape

InactiveCN109135604AIncrease brightnessImprove cooling effectPressure sensitive film/foil adhesivesHeat conductingSurface roughness

The invention discloses ultrathin EMI electromagnetic shielding adhesive tape. The adhesive tape includes a tape body, an optical PET layer, a buffer layer and a copper coil layer. The optical PET layer is arranged on one side of the interior of the tape body, a heat conducting layer is installed at the portion, on one side of the optical PET layer, of the interior of the tape body, and the bufferlayer is installed on the side, where the heat conducting layer is away from the optical PET layer, of the interior of the tape body; buffer strips are uniformly installed in the buffer layer, a resin thin film layer is installed on the side, where the buffer layer is away from the heat conducting layer, of the interior of the tape body, and an anti-corrosion layer is installed on the side, wherethe resin thin film layer is away from the buffer layer, of the interior of the tape body. By installing the copper coil layer at the portion, on one side of a first bonding layer, of the tape body,forming second saw teeth on both sides of the copper coil layer and installing the resin thin film layer in the tape body, the surface roughness and the contact surface can be effectively increased, the bonding force among the copper coil layer, an aluminum coil layer and a glue layer is enhanced, the structural stability of the adhesive tape is ensured, and meanwhile, the electromagnetic shielding capability of the adhesive tape is improved.

Owner:河源昆腾电子科技有限公司

High-strength industrial filter cloth and preparation method thereof

The invention discloses a high-strength industrial filter cloth and a preparation method thereof. The high-strength industrial filter cloth comprises, by weight, 30 to 40 parts of polyphenylene sulfide yarn, 5 to 10 parts of HDPE, 10 to 20 parts of nylon resin, 4 to 6 parts of polydimethylsiloxane, 0.3 to 0.6 part of carbon black and 6 to 10 parts of BuGong tea saponin. The invention has the following beneficial effects: the polyphenylene sulfide yarn and the nylon resin are used as base materials for preparation of the filter cloth, so the filter cloth has the advantages of high mechanical strength, high temperature resistance, resistance to chemicals, flame retardancy, good thermal stability, excellent electrical performance, etc.; meanwhile, the BuGong tea saponin is used as an additive, so the industrial filter cloth has greatly improved water-absorbing quality, luster and hand feeling.

Owner:铜陵华洋特种线材有限责任公司

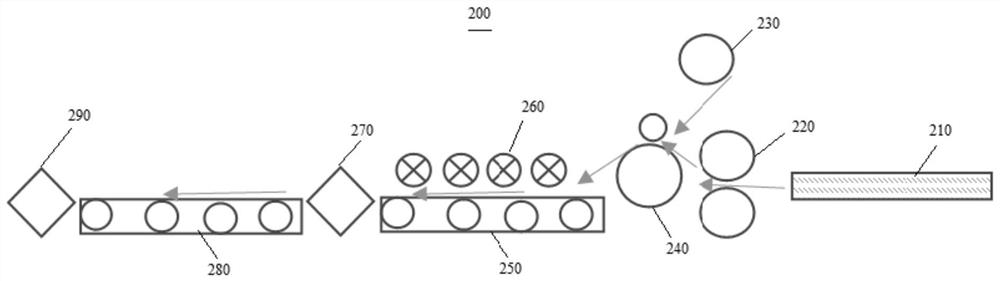

3D printing PVC floor and production method and production line thereof

PendingCN111907163AVarious printing effectsLow priceAdditive manufacturing apparatusSynthetic resin layered products3d printProduction line

The invention discloses a 3D printing PVC floor, a production method and a production line thereof, and belongs to the field of PVC floors. The 3D printing PVC floor comprises a PVC base material layer, a covering film and a 3D printing layer which are sequentially stacked from bottom to top, wherein the covering film is a polymer film. The 3D printing PVC floor production line comprises: an extruder for continuously extruding a PVC base material layer; a pair of laminating compression rollers for laminating and bonding the continuous PVC base material layer and a continuous laminating film together; a conveying platform for automatically conveying the PVC laminating film layer; a cooling mechanism for cooling the PVC laminating film layer; a 3D printer for carrying out 3D printing on thesurface of the PVC laminating film layer to form a 3D printing layer; and a cutting machine. According to the 3D printing PVC floor, the production method and production line thereof, continuous and automatic production of the 3D printing PVC floor is achieved, the decoration effect of the product is diversified, and deformation is avoided.

Owner:CHANGZHOU BEMATE HOME TECH CO LTD

Anti-wrinkle silver reflecting film and processing technology thereof

InactiveCN111730944AAvoid direct contactImprove wrinklesMirrorsSynthetic resin layered productsPolyesterPolymer science

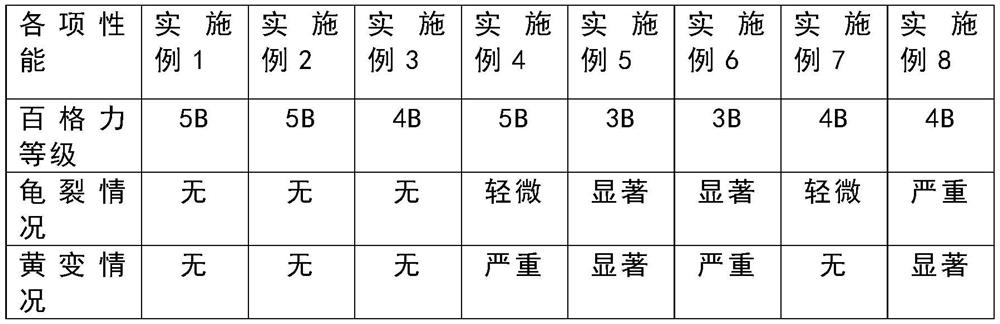

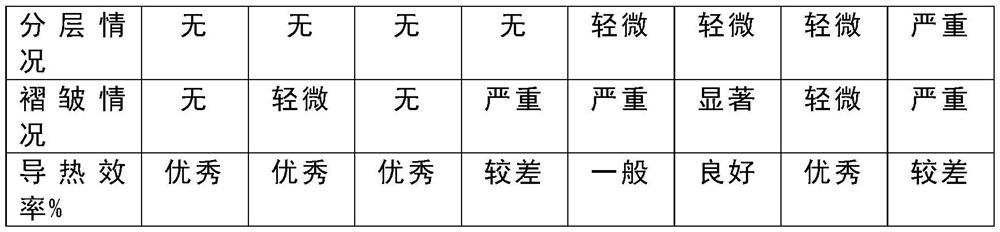

The invention discloses an anti-wrinkle silver reflecting film and a processing technology thereof. The processing technology comprises the steps that heat conduction powder A and heat conduction powder B are mixed, a solvent is poured into the mixture to prepare heat conduction powder slurry, then an anti-aging oxidation auxiliary, polyurethane resin and the solvent are stirred and mixed, the heat conduction powder slurry is added, and a heat conduction coating is prepared; the upper surface and the lower surface of a PET film are coated with the heat conduction coating at the coating speed of 1.3-1.5 g / m<2> and the coating speed of 0.6-0.9 g / m<2> correspondingly, and a heat conduction pre-coating film is prepared; and the heat conduction pre-coating film and the silver plating film are attached together through polyester-polyurethane glue, and an anti-wrinkle silver reflecting film is obtained. According to the anti-wrinkle silver reflecting film and the processing technology thereof, the prepared silver reflecting film has good anti-wrinkle performance, aging and layering phenomena do not occur even if the silver reflecting film works in a high-temperature environment for a longtime, the adhesion between film layers is good, and the practicability is high.

Owner:JIANGSU SUNDERRAY LASER PACKAGING MATERIALS CO LTD

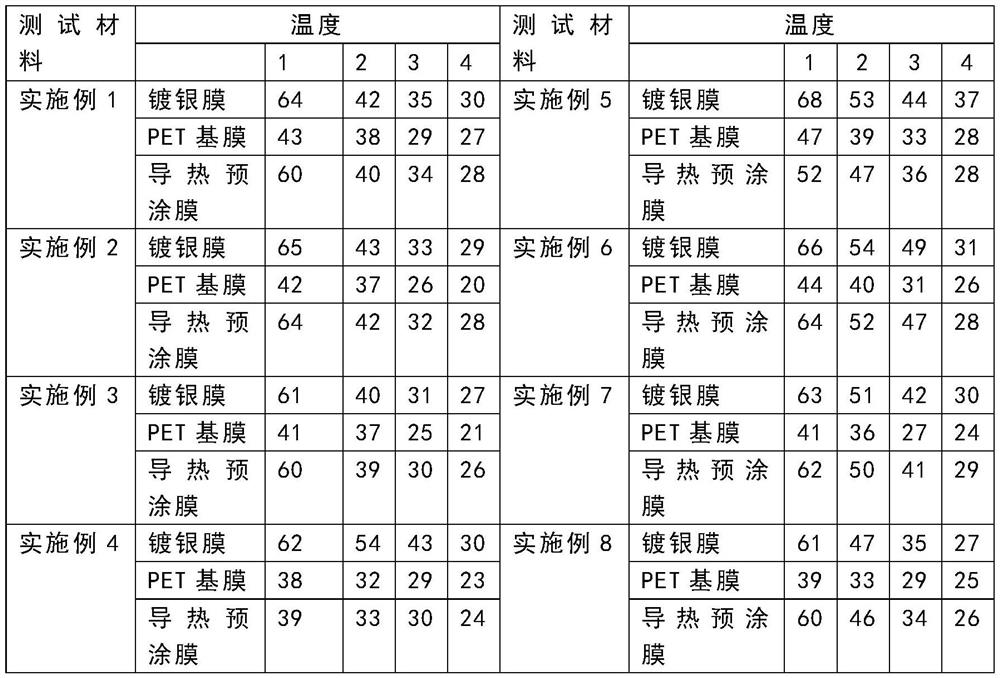

Improved anti-pollution flashover coating and preparation method thereof

The invention discloses an improved anti-pollution flashover coating, which is prepared from the following ingredients in parts by weight: 100 parts of hydroxyl-terminated polydimethylsiloxane, 10 to 20 parts of white carbon black, 15 to 50 parts of aluminum hydroxide, 20 to 50 parts of aluminum oxide microspheres, 15 to 30 parts of decabromodiphenyl ether, 5 to 10 parts of pigments, 200 to 300 parts of mixed solvents, 1 to 5 parts of silane coupling agents, 1 to 10 parts of cross-linking agents, 0.5 to 5 parts of catalysts and 5 to 20 parts of lubricating agents. The invention also discloses a preparation method of the improved anti-pollution flashover coating. According to the improved anti-pollution flashover coating disclosed by the invention, aluminum hydroxide and aluminum oxide microspheres with different particle sizes are compounded, and the lubricant is matched, so that the improved anti-pollution flashover coating can greatly reduce the adhesive force of covering ice on the surface of equipment; when the surface of equipment operating outdoors is iced, compared with a traditional anti-pollution flashover coating, the anti-pollution flashover coating can enable ice to fall off more quickly, so that the influence of frost on the operating equipment is reduced.

Owner:河北诚和龙盛电力工程有限公司 +2

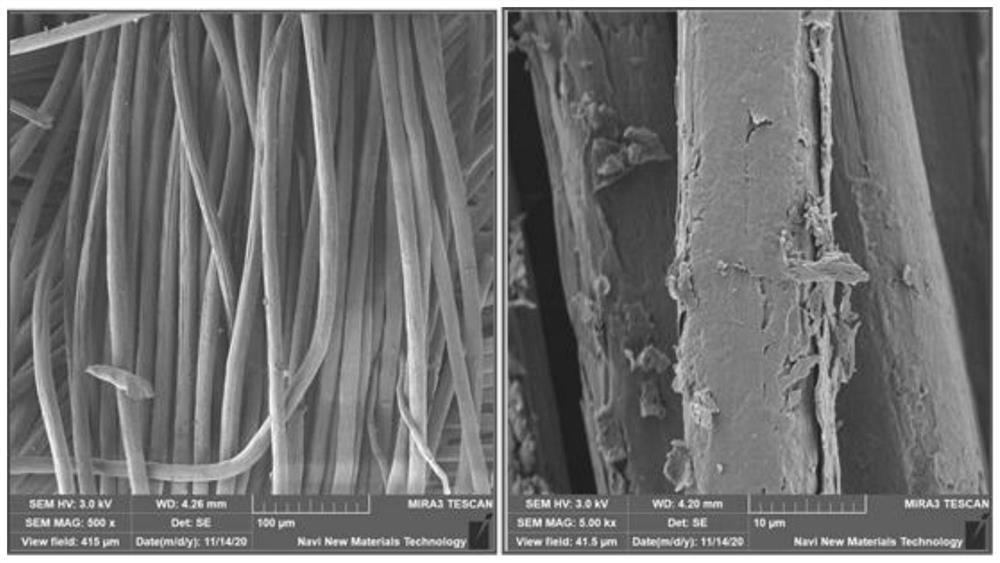

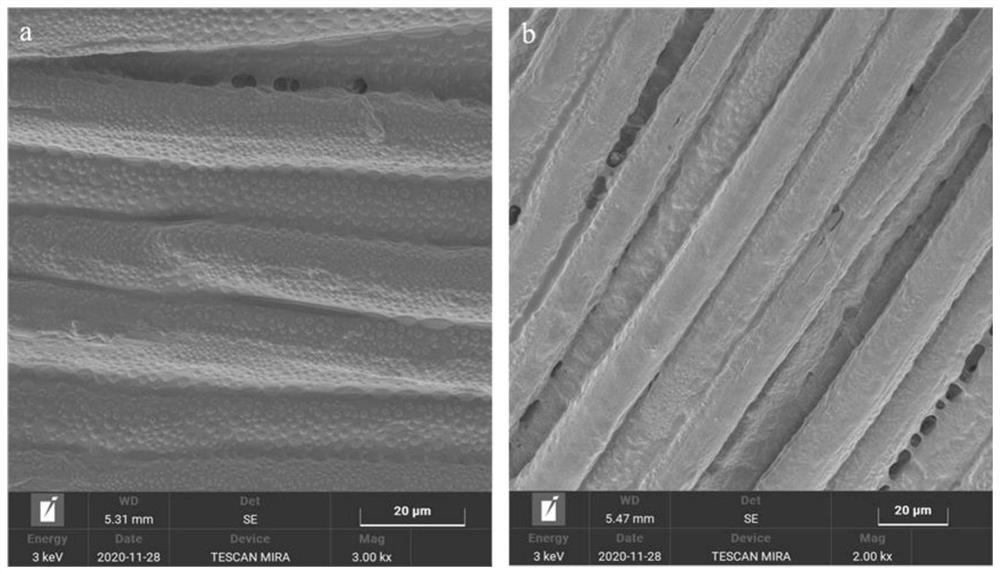

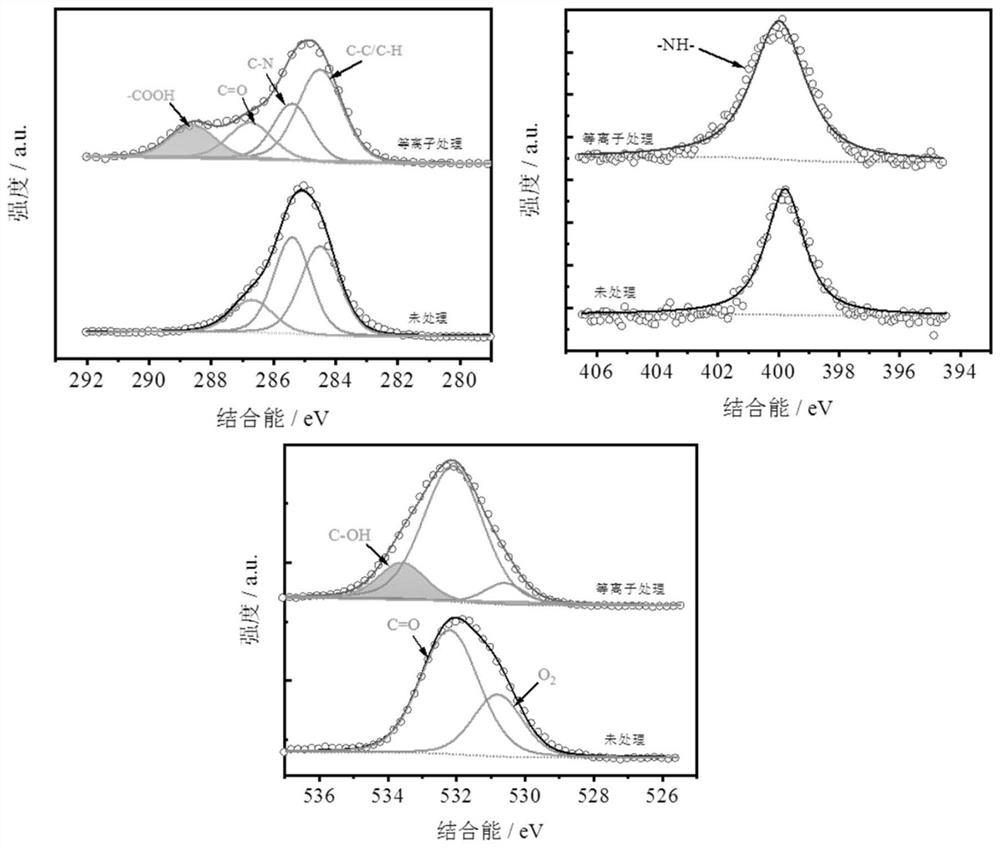

Method for improving dyeing performance of aramid fiber cloth

PendingCN112962326AMechanical strength has no effectImprove adhesionPhysical treatmentFibre typesPolymer scienceNitrogen plasma

The invention discloses a method for improving the dyeing performance of aramid fiber cloth. The method for improving the dyeing performance of the aramid fiber cloth comprises the following steps of S1, carrying out plasma treatment on the aramid fiber cloth; and S2, blade-coating the aramid fiber cloth modified in the step S1 with resin slurry to improve the dyeing performance of the aramid fiber cloth, wherein the plasma treatment is oxygen plasma treatment or nitrogen plasma treatment. The method is suitable for dyeing modification of domestic para-aramid and meta-aramid fiber cloth (aramid fiber 1313 and aramid fiber 1414) and foreign imported aramid fiber cloth, and the dyed aramid fiber cloth can be applied to manufacturing of military camouflage protection, weapon covering cloth, special fabrics and clothes. According to the method for improving the dyeing performance of the aramid fiber cloth, the flame-retardant and high-strength performance of the aramid fiber cloth can be kept, the dye-uptake rate of the aramid fiber cloth is greatly increased, and the binding strength between dye and the aramid fiber cloth and the soaping resistance of the dyed cloth are enhanced.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

Composite resin based corrosion-resistant floor and preparation method thereof

InactiveCN105295239AGood heat stabilityStop heat from spreadingFlooringAmmonium sulfateZirconium oxychloride octahydrate

The invention discloses a composite resin based corrosion-resistant floor. The composite resin based corrosion-resistant floor comprises the following raw materials in parts by weight: 1-2 parts of potassium hydrogen sulfate, 6-10 parts of diatomite, 17-20 parts of zirconium oxychloride octahydrate, 10-15 parts of 40%-47% hydrochloric acid, 90-100 parts of 80%-85% phosphoric acid, 3-4 parts of tetrahydroxymethyl phosphonium sulfate, 4-7 parts of 25%-30% methylamine water solution, 5-7 parts of trifluoroethyl methacrylate, 0.2-0.4 part of 2-octyl-4-isothiazolin-3-one, 0.06-0.1 part of ammonium persulfate, 0.01-0.02 part of divinyl benzene, 1-2 parts of azodicarbonamide, 130-170 parts of polyvinyl chloride, 6-8 parts of polyoxyethylene oleate, 20-30 parts of polypropylene, 1-2 parts of hydroxyacetic acid, 3-5 parts of allyl polyethylene glycol and 3-4 parts of magnesium stearate. By blending polypropylene and polyvinyl chloride into a plastic main body, the strength and the acid-alkali resistances of a finished product can be effectively improved, and the comprehensive quality of the product is improved.

Owner:CHUZHOU YONGTONG TRAFFIC EQUIP

Thermosetting resin composition, prepreg using thermosetting resin composition, laminated board and printed circuit board

ActiveCN110845706AImprove flame retardant performanceImprove solder dip resistanceSynthetic resin layered productsMetal layered productsPolymer scienceDip soldering

Owner:SHAANXI SHENGYI TECH

Ceramic diaphragm and preparation method and application thereof, and battery comprising ceramic diaphragm

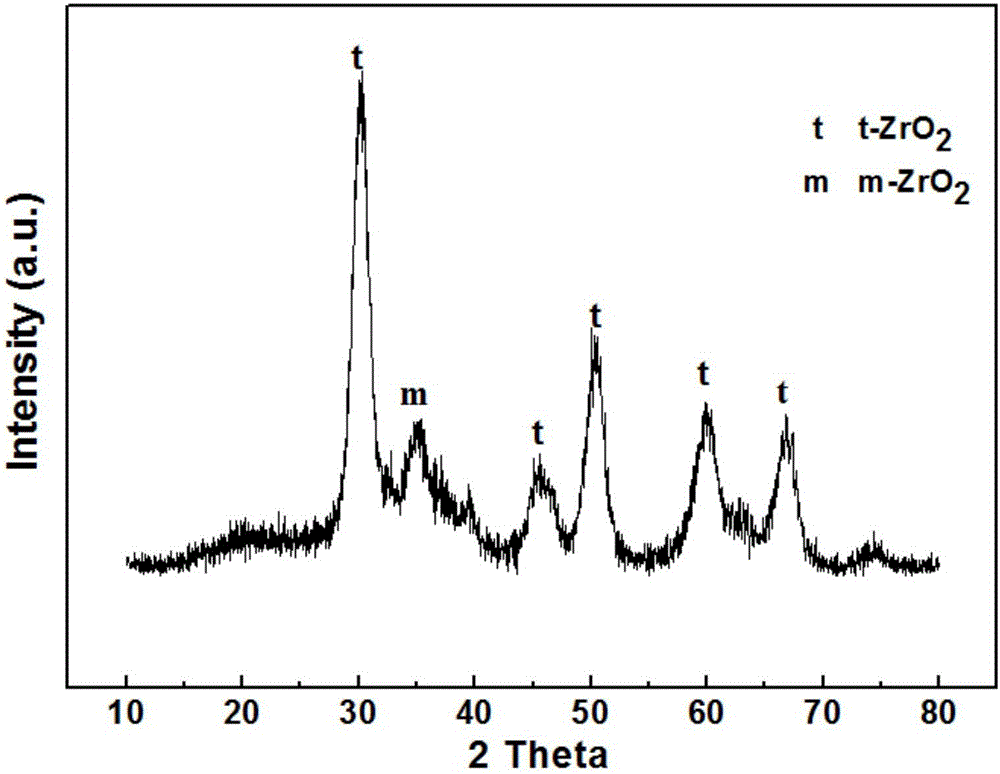

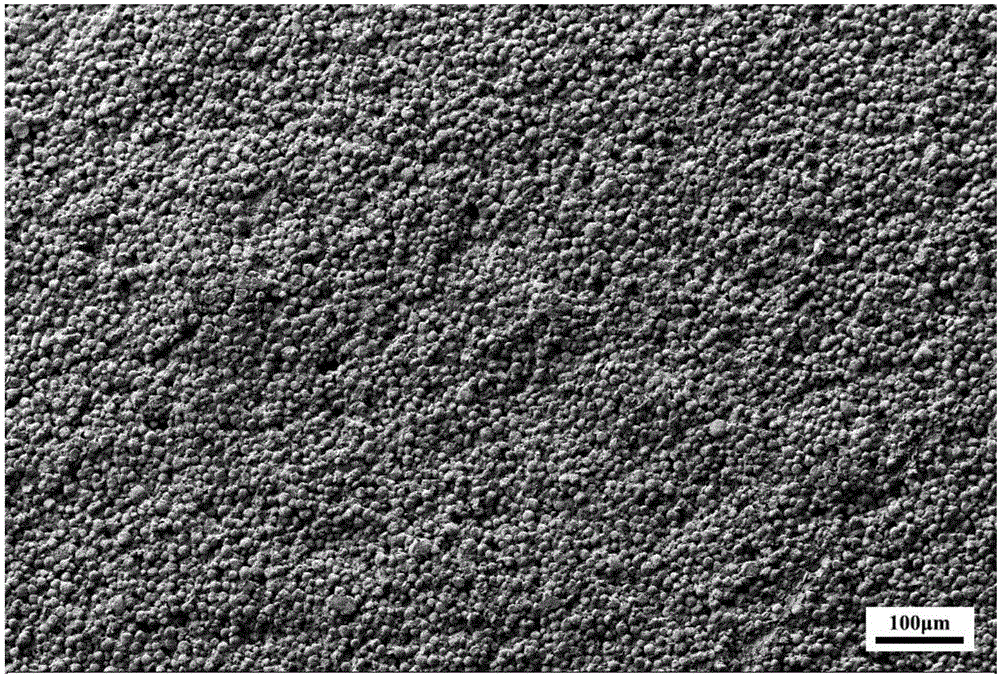

InactiveCN106711379AFlame retardant temperature stabilityKeep the temperature stableSecondary cellsCell component detailsYttriumPolyolefin

The invention discloses a ceramic diaphragm and a preparation method and application thereof, and a battery comprising the ceramic diaphragm. The ceramic diaphragm comprises a base material and a ceramic coating compounded on at least one surface of the base material, wherein the ceramic coating is prepared from two or more ceramic powder and a binder; the ceramic powder comprises a main component tetragonal zirconia and a toughened component; the toughened component is one or two or more of cerium oxide, hafnium oxide and magnesium oxide; and the toughened component can be yttrium oxide. Due to the doped toughened component, zirconium oxide can exist in a metastable tetragonal phase at a room temperature, the prepared ceramic powder coats the membrane of taking a polyolefin microporous membrane as the base material, and the zirconium oxide in the tetragonal phase is mutated into zirconium oxide in a monoclinic phase during a sudden rise of the temperature or an impact of external force to absorb one part of energy, so that an effective flame-retardant effect can be achieved, and the stable temperature can be effectively ensured; and the preparation method of the ceramic membrane is simple in process and good in repeatability and has very high promotion and application values.

Owner:JIANGSU CHUHAN ENERGY TECH CO LTD

Silicone-acrylic emulsion anticorrosive floor and preparation method thereof

InactiveCN105295233AImprove heat stabilityPlay a barrier roleFlooringPolyvinyl alcoholPolyvinyl chloride

The invention discloses a silicone-acrylic emulsion anticorrosive floor consisting of the following raw materials in parts by weight: 10-14 parts of silicone-acrylic emulsion, 1-2 parts of copper 8-hydroxyquinoline, 17-20 parts of zirconium oxychloride octahydrate, 10-15 parts of 40-47% hydrochloric acid, 90-100 parts of 80-85% phosphoric acid, 3-4 parts of tetrakis(hydroxymethyl) phosphonium sulfate, 4-7 parts of 25-30% methylamine water solution, 5-7 parts of trifluoroethyl methacrylate, 0.2-0.4 part of 2-octyl-2H-isothiazol-3-one, 0.06-0.1 part of ammonium persulfate, 0.01-0.02 part of divinylbenzene, 1-2 parts of azodicarbonamide, 130-200 parts of polyvinyl chloride, 6-7 parts of polyurethane, 1-2 parts of sodium hydrogen sulfite, 0.7-1 part of beta-hydroxyl alkyl amide, 7-10 parts of borax and 4-5 parts of polyvinyl alcohol. The silicone-acrylic emulsion is added into the silicone-acrylic emulsion anticorrosive floor disclosed by the invention, so that the surface strength and impact resistance of a finished plate are improved, the compatibility among all the materials is improved, and the stability and strength of a finished product are improved.

Owner:CHUZHOU YONGTONG TRAFFIC EQUIP

Impact-resistance and corrosion-prevention floor and preparing method thereof

The invention discloses an impact-resistance and corrosion-prevention floor. The impact-resistance and corrosion-prevention floor is prepared from, by weight, 6-7 parts of dioctyl azelate, 17-20 parts of zirconium oxychloride octahydrate, 10-15 parts of hydrochloric acid with the concentration of 40-47%, 90-100 parts of phosphoric acid with the concentration of 80-85%, 3-4 parts of tetrakis hydroxymethyl phosphonium sulfate, 4-7 parts of a methylamine water solution with the concentration of 25-30%, 5-7 parts of trifluoroethyl methacrylate, 0.2-0.4 part of 2-octyl-2H-isothiazol-3-one, 0.06-0.1 part of ammonium persulphate, 0.01-0.02 part of divinyl benzene, 1-2 parts of azodicarbonamide, 170-200 parts of polyvinyl chloride, 10-14 parts of scolecite, 2-4 parts of polyethylene imine, 0.3-1 part of ammonium ethoxylated alkyl sulfate, 1-3 parts of sodium benzoate and 2-4 parts of calcium ricinoleate. The floor has good impact resistance and is good in bearing performance and high in safety.

Owner:CHUZHOU YONGTONG TRAFFIC EQUIP

Combed cotton/graphene polyamide interweaved fabric and production process thereof

InactiveCN111005121AReduce usageGuaranteed additional featuresOrnamental textile articlesDyeing processPolymer sciencePolyamide

The invention discloses a combed cotton / graphene polyamide interweaved fabric and a production process thereof. The combed cotton / graphene polyamide interweaved fabric comprises the following components of 60-80 parts of combed cotton and 20-40 parts of graphene polyamide, wherein the combed cotton is the surface, and the graphene polyamide is the bottom. The production process of the combed cotton / graphene polyamide interweaved fabric comprises the following steps of weaving; pre-treatment; primary dyeing; peracid neutralization; first post-treatment; secondary dyeing; second post-treatment;squeezing; and setting. The combed cotton / graphene polyamide interweaved fabric has the characteristics of good wear resistance, better strength, soft hand feeling, difficult wrinkling after water washing and the like; without adding any functional auxiliary agent, the fabric can be endowed with the antistatic, antibacterial, anti-ultraviolet, far-infrared, anti-mite and deodorization functions and other functions; and a high-washability product provided with the functional auxiliary agent realizes the multi-functionality and durability of the fabric.

HDPE/PVC blended modified material

The invention discloses an HDPE (high-density polyethylene) / PVC (polyvinyl chloride) blended modified material, and belongs to the technical field of resin materials. The blended modified material comprises the following components in parts by weight: HDPE, PVC, a compatibilizer, a coupling agent, a heat stabilizer, a filler, a lubricant, a plasticizer and an impact modifier; the compatibilizer is maleic anhydride grafted polyethylene and maleic anhydride grafted polypropylene; and the filler is basic magnesium sulfate whiskers activated by PMMA and talcum powder. According to the HDPE / PVC blended modified material provided by the invention, the basic magnesium sulfate whisker and the talcum powder are modified by utilizing the hard PMMA, so that the adhesive force of an obtained finished product to a paint film can be improved, and meanwhile, the dispersity and compatibility of a filler in an HDPE / PVC blended polymer are favorably improved.

Owner:福建亚通新材料科技股份有限公司

Halogen antimony-free resin composition, prepreg using same, laminated board and printed circuit board

ActiveCN109306149AImprove flame retardant performanceBreak the technical bottleneck that cannot be replacedPaper/cardboard layered productsElectrical equipmentEpoxyHalogen

The invention provides a halogen antimony-free resin composition, a prepreg using the same, a laminated board and a printed circuit board. The halogen antimony-free resin composition comprises the following components in parts by weight: 25 to 70 parts of flame-retardant epoxy resin, 10 to 40 parts of non-flame-retardant epoxy resin, 20 to 60 parts of a curing agent, and 0.05 to 1.0 part of a curing accelerant; and the flame-retardant epoxy resin comprises a composition of phosphorus-comprising epoxy resin, bromination epoxy resin and nitrogen-comprising epoxy resin. By virtue of the cooperation of the flame-retardant epoxy resin and non-flame-retardant epoxy resin, especially the cooperation of three flame-retardant epoxy resin, a phosphorus-bromine-nitrogen synergistic flame-retardant effect can be achieved, a CEM-1 copper-coated laminated board is good in flame retardant property, the technical bottle neck that the halogen antimony synergistic flame-retardant system in the traditional halogen CEM-1 copper-coated laminated board cannot be replaced is broken through, and the halogen antimony-free resin composition has the advantages of significant comprehensive performance such ashigh heat resistance, high damp heat resistance and the like.

Owner:SHAANXI SHENGYI TECH

Halogen-free and antimony-free resin composition, prepreg, laminate and printed circuit board using same

ActiveCN109354827BImprove heat resistanceLow water absorptionSynthetic resin layered productsLaminationPolymer scienceAntimony compounds

Owner:SHAANXI SHENGYI TECH

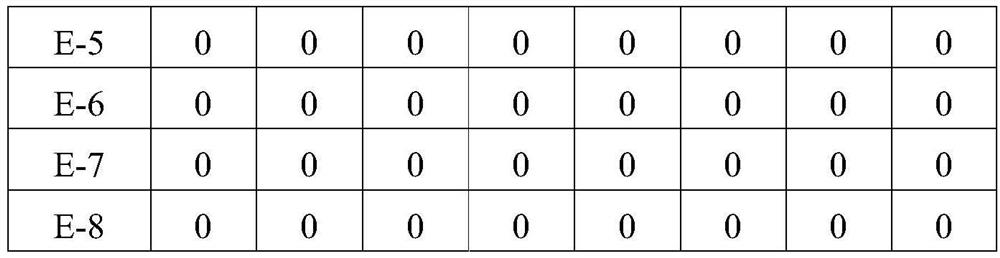

A kind of thermoplastic polyetherimide insulating and heat-conducting composite material and preparation method thereof

ActiveCN108250747BGuaranteed insulation performanceImprove insulation performanceImidePolymer science

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

High Performance Construction Cables

ActiveCN103310893BImprove crack resistanceImprove environmental aging resistanceInsulated cablesInsulated conductorsInterference resistanceElectrical conductor

The invention discloses a high-performance cable for construction. The high-performance cable for construction solves the problem that the existing cable for construction is low in fire resistance, poor in weather resistance, short in service life and the like. The high-performance cable for construction has the advantages of being environmentally friendly, inflaming retarding, waterproof, moistureproof, strong in antijamming capability, excellent in electric performance, long in service life and the like. The high-performance cable for construction structurally comprises a cable core which is composed of a plurality of insulating wire cores arranged in a filling body, each insulating wire core comprises a conductor and a double-layer co-extrusion heterogeneous insulating layer arranged outside the conductor in a pressing and wrapping mode, and the cable core is sequentially wrapped by a wrapping layer, a cable shielding layer, an oxygen separating layer, an armor layer and a cable outer sheath sequentially from inside to outside.

Owner:SHANGDONG HUALING CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com