A kind of thermoplastic polyetherimide insulating and heat-conducting composite material and preparation method thereof

A polyetherimide and polyetherimide resin technology, which is applied in the field of polymer functional composite materials, can solve the problems of losing insulation properties, not considering the shape and particle size of fillers, etc., and achieves improved thermal conductivity and comprehensive performance. Excellent and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

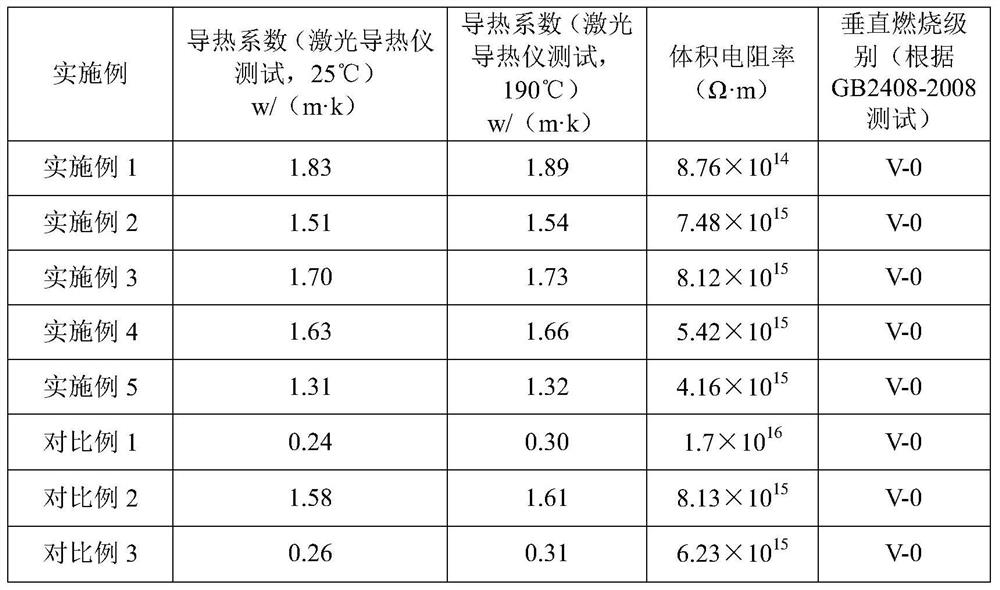

Embodiment 1

[0036]40 parts of polyetherimide and 50 parts of boron nitride (surface-treated with silane coupling agent γ-(2,3-epoxypropoxy)propyltrimethoxysilane accounting for 2.5 wt% of boron nitride mass) , 5 parts of zinc oxide whiskers (surface-treated with γ-(methacryloyloxy)propyltrimethoxysilane accounting for 1 wt% of the quality of zinc oxide whiskers) and 5 parts of polyethylene wax after mixing uniformly in a high-speed mixer , added to a twin-screw extruder for uniform plasticization, extrusion, and granulation. The twin-screw extrusion temperature is 345° C., and the screw speed is 200 rpm. The obtained pellets were made into insulating and heat-conducting composite materials by injection molding. The injection molding temperature was 360° C. and the injection molding pressure was 40 MPa. The properties are shown in Table 1.

Embodiment 2

[0038] 48 parts of polyetherimide, 40 parts of aluminum nitride (surface treated with silane coupling agent 3-aminopropyltriethoxysilane accounting for 1 wt% of aluminum nitride quality), 10 parts of potassium titanate whiskers ( After being treated with silane coupling agent γ-(2,3-epoxypropoxy)propyltrimethoxysilane (2,3-epoxypropoxy)propyltrimethoxysilane surface treatment) and 2 parts of liquid paraffin in a high-speed mixer, Carry out extrusion and injection molding, processing condition is the same as embodiment 1, and its performance is as shown in table 1.

Embodiment 3

[0040] 46 parts of polyetherimide, 30 parts of silicon carbide (surface treated with γ-(methacryloyloxy)propyl trimethoxysilane accounting for 3wt% of the mass of silicon carbide), 20 parts of boron nitride (treated with nitrogen γ-(2,3-epoxypropoxy)propyltrimethoxysilane surface treatment with 3wt% of the mass of boron oxide), 1 part of potassium titanate whiskers (through n-propanol which accounts for 3wt% of the mass of potassium titanate whiskers Zirconium (IV) surface treatment) and 3 parts of polyethylene wax were mixed uniformly in a high-speed mixer, then added to an internal mixer for plasticization and mixing, the mixing temperature was set at 340 ° C, and the rotor speed was 50 rpm; The insulating and heat-conducting composite material was made by hot-pressing on the press. The hot-pressing temperature was 360°C and the hot-pressing pressure was 30 MPa. The properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com