3D printing PVC floor and production method and production line thereof

A 3D printing and 3D printer technology, applied in the field of 3D printing PVC floor and its production method and production line, can solve the problems of unable to meet the requirements of diversified floor effects, unable to obtain three-dimensional floor effect, and single effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

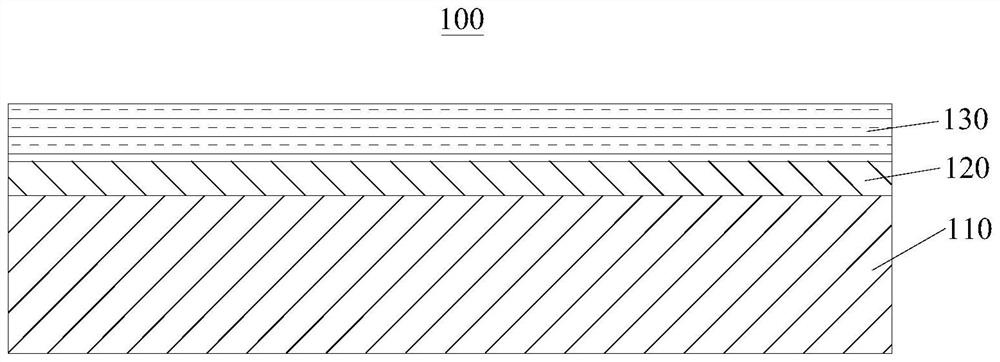

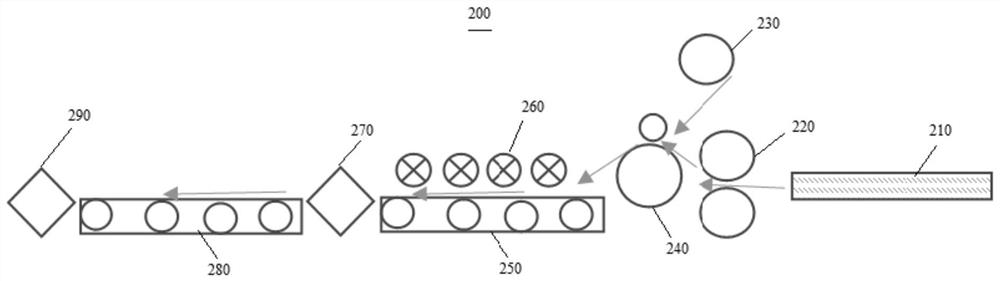

[0075] Such as figure 1 and figure 2 As shown, this embodiment provides a 3D printed PVC floor 100, which adopts the above-mentioned production line 200, and is manufactured according to the following process:

[0076] After the extruder 210 extrudes the continuous PVC base material layer 110, the PVC base material layer 110 with a specified size and thickness of 4mm is obtained by calendering 1 roll and calendering 2 roll of the calender roll 220, and then enters the laminated pressure roll 240 (between calendering 3 rolls and lamination rolls); simultaneously tension machine 230 makes the PVC white film of 0.7mm thickness enter between lamination pressure rolls 240 (calendering 3 rolls and lamination 120 rolls) as lamination film 120, thereby Cover the PVC white film on the PVC base material layer 110 to form a PVC film layer; then advance on the first conveying platform 250, and simultaneously, 5 groups of cooling fans around the first conveying platform 250 simultaneousl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com