Method for improving dyeing performance of aramid fiber cloth

A technology for the dyeing performance of aramid fiber cloth, applied in the direction of dyeing method, fiber type, fiber treatment, etc., can solve the problems such as difficult dyeing of aramid fiber cloth, achieve enhanced binding fastness, simple process, and increase dye uptake rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1, the dyeing property improvement of aramid fiber cloth

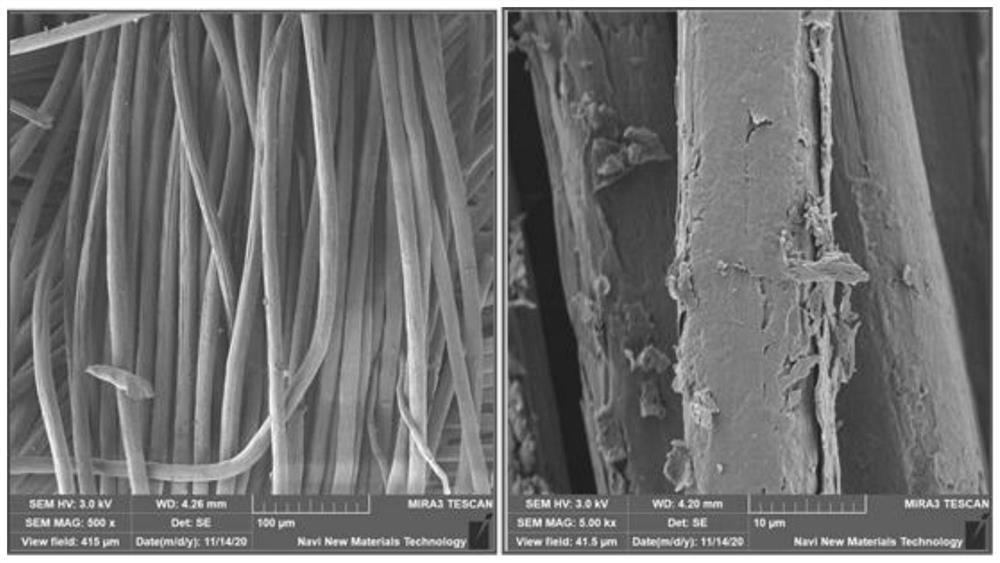

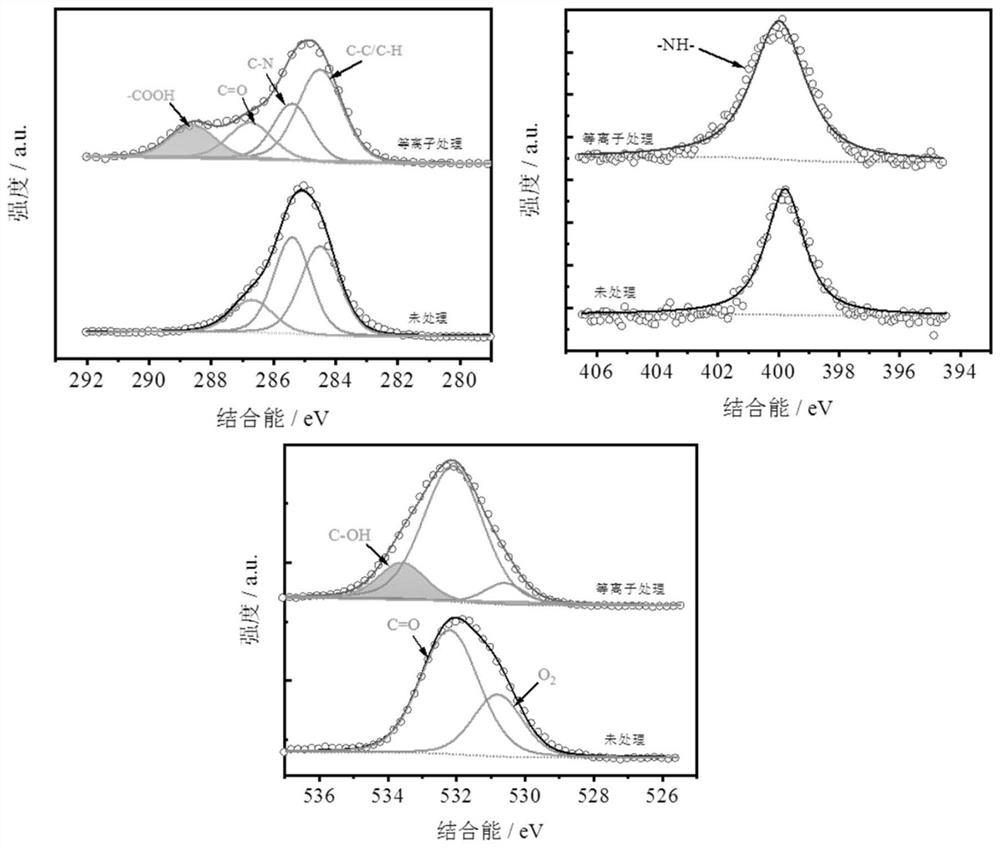

[0061] S1: Arrange the aramid fiber 1313 fiber in the oxygen plasma treatment apparatus, adjust the plasma treatment power to 300W, and the treatment time is 20 minutes to obtain the aramid fiber cloth after oxygen plasma treatment, and its scanning electron microscope photo is as follows figure 1 shown.

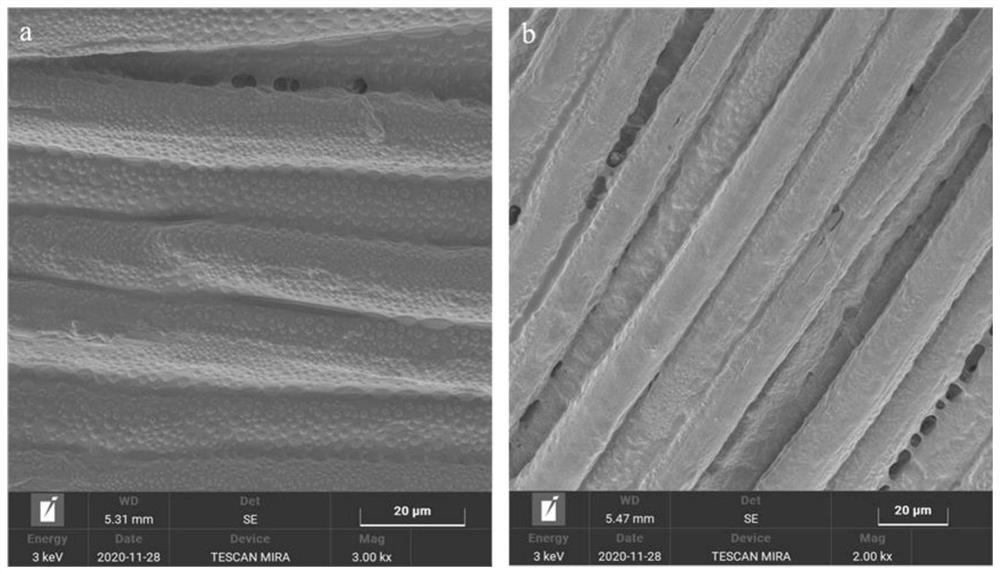

[0062] S2: Weigh the resin (polyurethane) and additives according to the mass ratio of 20:4, and then disperse them in the solvent DMF (N,N-dimethylformamide) (the amount is 8ml / g polyurethane), at 1000r / min Disperse at a high speed for 10 minutes to obtain a resin slurry, and scrape the resin slurry on the plasma-modified aramid cloth with a scraping method, and the dosage is 6g / m 2 , to obtain the final modified aramid fabric, and its scanning electron microscope photos are as follows figure 2 shown.

[0063] Among them, the additives include flame retardant, dispersant, defoamer, leveling age...

Embodiment 2

[0067] Embodiment 2, the dyeing performance improvement of aramid fiber cloth

[0068] The steps are the same as in Example 1, except that the polyurethane used in the resin modification treatment is replaced with epoxy resin (LANXESS S10 series resin).

Embodiment 3

[0069] Embodiment 3, dyeing of aramid fiber cloth

[0070] Aramid 1313 fiber cloth without any treatment, aramid 1313 fiber cloth treated with oxygen plasma in Example 1 (step S1), aramid 1313 fiber cloth modified in Example 1 and modified in Example 2 The final aramid 1313 fiber cloth is dyed, and the dyeing steps are as follows:

[0071] S1: Weigh 30 parts of deionized water, and add high-temperature disperse leveling agent (HT424 leveling agent from Huashen Company) at a concentration of 1g / L, stir evenly, add a small amount of acetic acid to adjust the pH value to about 5, and then Weigh 1.5 parts of quality disperse dyes (as shown in Table 1) and add therein, and stir evenly to obtain a dye solution for exhaust dyeing.

[0072] S2: Weigh 2 parts of the modified and unmodified aramid fabrics with a balance, immerse all the aramid fabrics in the dye solution prepared in S1 at room temperature, raise the temperature until the dye solution boils, and keep it for 90 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com