A kind of application of surface modifier composition

A surface modifier and surface modification technology, applied in the field of plastic additives, can solve the problems of large amount of addition, ineffective effect, and reduction of plastic mechanical strength, etc., to achieve small amount of addition, increase adhesion, and increase polarity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

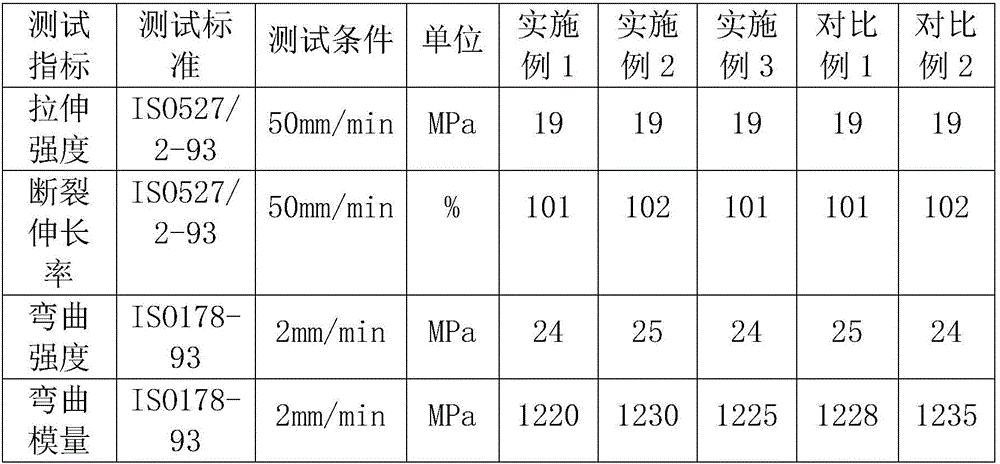

Examples

Embodiment 1

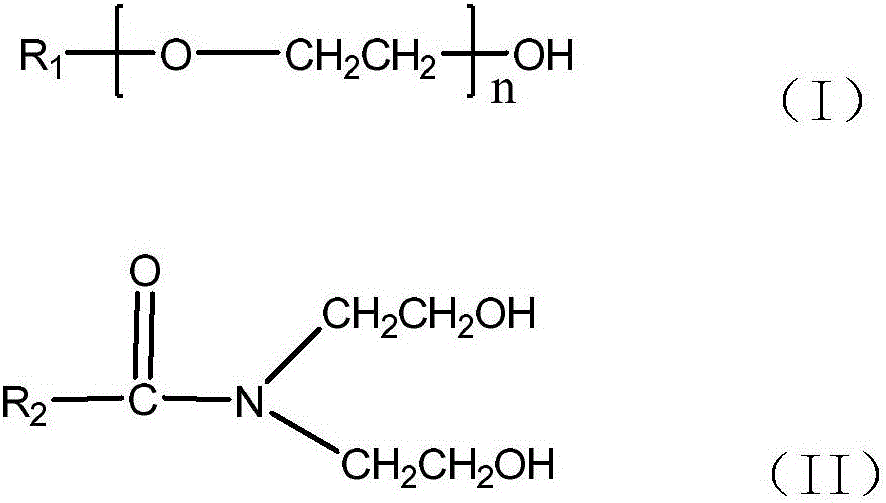

[0023] (1) Synthesis of component A:

[0024] In a three-necked flask, add 253g of cetearic and stearyl alcohol, 1g of potassium hydroxide, control the vacuum degree below 1KPa, heat to 150°C-160°C for complete dehydration, then fill it with nitrogen, control the temperature at 130°C-160°C, and stir Add 150g of ethylene oxide, the addition time is about 1.5~2h, and react for half an hour after adding, then cool and discharge to obtain component A;

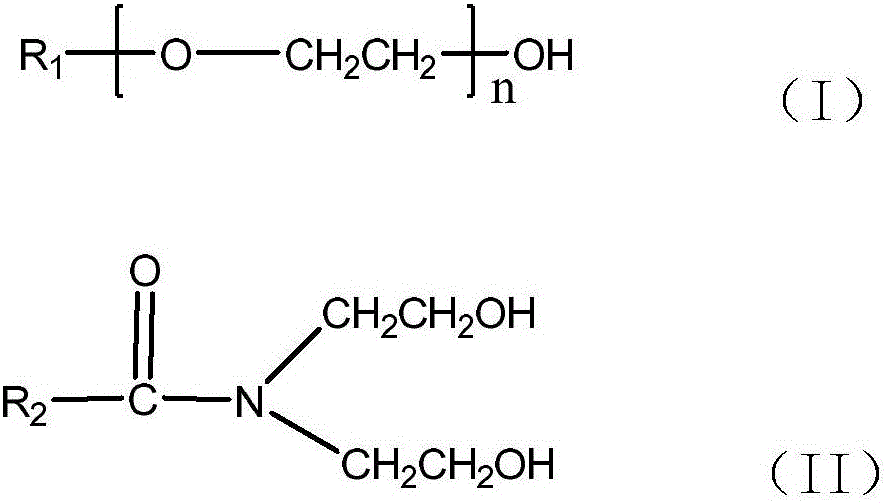

[0025] (2) Synthesis of component B:

[0026] In a three-necked flask, add 267g of stearic acid, 105g of diethanolamine, and 1g of potassium hydroxide, raise the temperature to 120°C~160°C, maintain the vacuum at -0.096~-0.098Mpa, react for 3 hours, and detect that the acid value is less than 1mgKOH / g So far, component B is obtained;

[0027] (3) Preparation of surface modifier composition for engineering plastics:

[0028] Stir and mix the synthesized component A and the synthesized component B, wherein the weight ratio of comp...

Embodiment 2

[0030] (1) Synthesis of component A:

[0031] In a three-necked flask, add 303g of tetracosanol and 1g of potassium hydroxide, control the vacuum degree below 1KPa, heat to 150°C-160°C for complete dehydration, then fill with nitrogen, and control the temperature at 130°C-160°C , stirring and adding 200g of ethylene oxide, the addition time is about 1.5~2h, the reaction is half an hour after the addition is completed, then cooled, and the material is discharged to obtain component A;

[0032] (2) Synthesis of component B:

[0033] In a three-necked flask, add 300g of behenic acid, 105g of diethanolamine, and 1g of potassium hydroxide, raise the temperature to 120°C~160°C, keep the vacuum at -0.096~-0.098MPa, react for 3 hours, and detect that the acid value is less than 1mgKOH / g So far, component B is obtained;

[0034] (3) Preparation of surface modifier composition for engineering plastics:

[0035] Stir and mix the synthesized component A and the synthesized component B,...

Embodiment 3

[0037] (1) Synthesis of component A:

[0038] In a three-necked flask, add 303g of tetracosanol and 1g of potassium hydroxide, control the vacuum degree below 1KPa, heat to 150°C-160°C for complete dehydration, then fill with nitrogen, and control the temperature at 130°C-160°C , stirring and adding 200g of ethylene oxide, the addition time is about 1.5~2h, the reaction is half an hour after the addition is completed, then cooled, and the material is discharged to obtain the composition A;

[0039] (2) Synthesis of component B:

[0040] In a three-necked flask, add 267g stearic acid, 105g diethanolamine, and 1g potassium hydroxide, raise the temperature to 120°C~160°C, maintain the vacuum at -0.096~-0.098MPa, and react for 3 hours. The acid value is less than 1mgKOH / g So far, get the composition B

[0041] (3) Preparation of surface modifier composition for engineering plastics:

[0042] Stir and mix the synthesized component A and the synthesized component B, wherein the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com