Halogen antimony-free resin composition, prepreg using same, laminated board and printed circuit board

A resin composition and prepreg technology, applied in laminates and printed circuit boards, halogen-free antimony resin compositions, and prepreg fields, can solve problems such as low correlation, and achieve breakthroughs in technical bottlenecks and good performance. The effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8 and comparative example 1~11

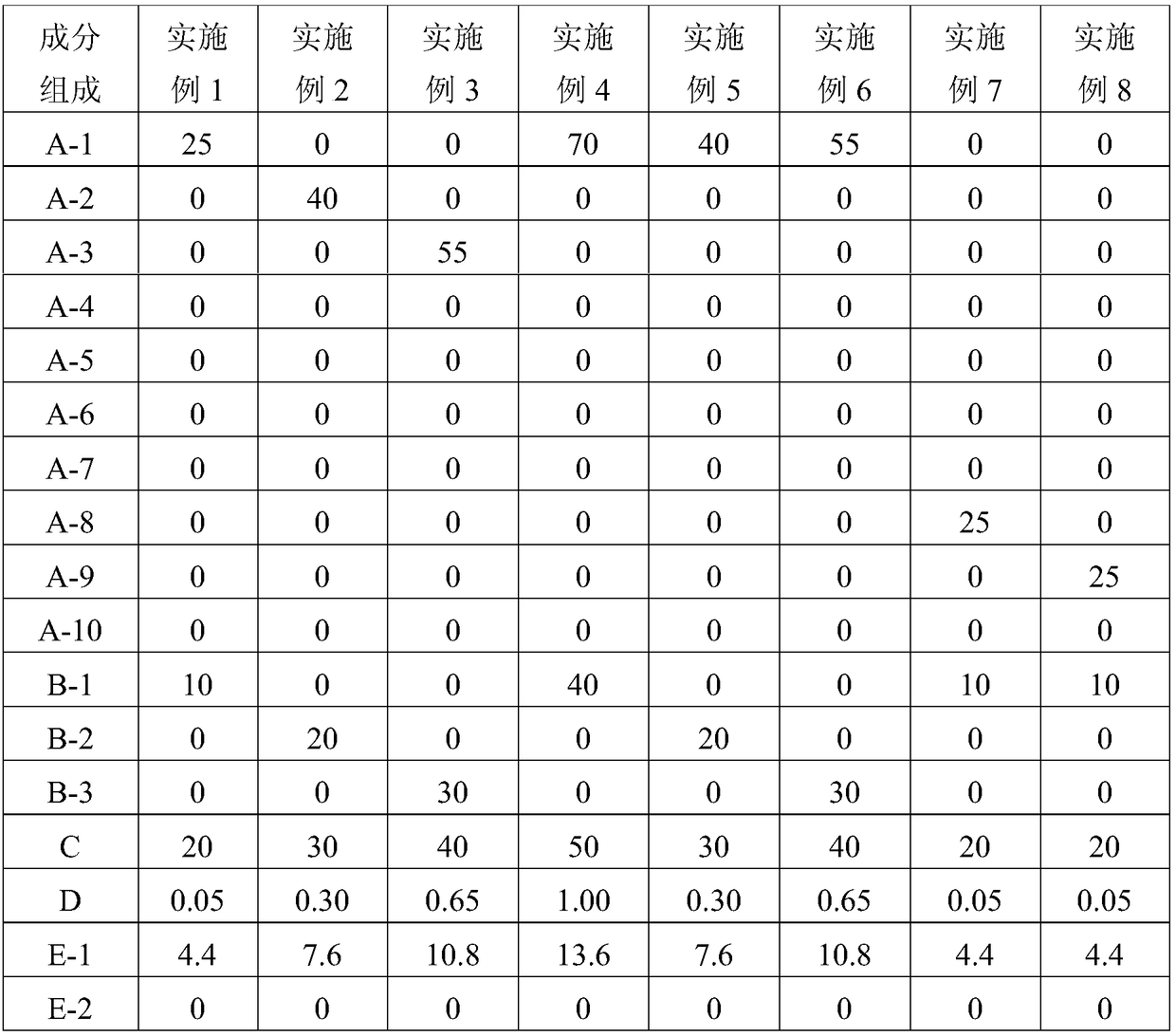

[0060] The specific components and component contents (in parts by weight) of the resin compositions of Examples 1-8 and Comparative Examples 1-11 are shown in Table 1 and Table 2.

[0061] Concrete components and component content of the resin composition of table 1 embodiment 1~8

[0062]

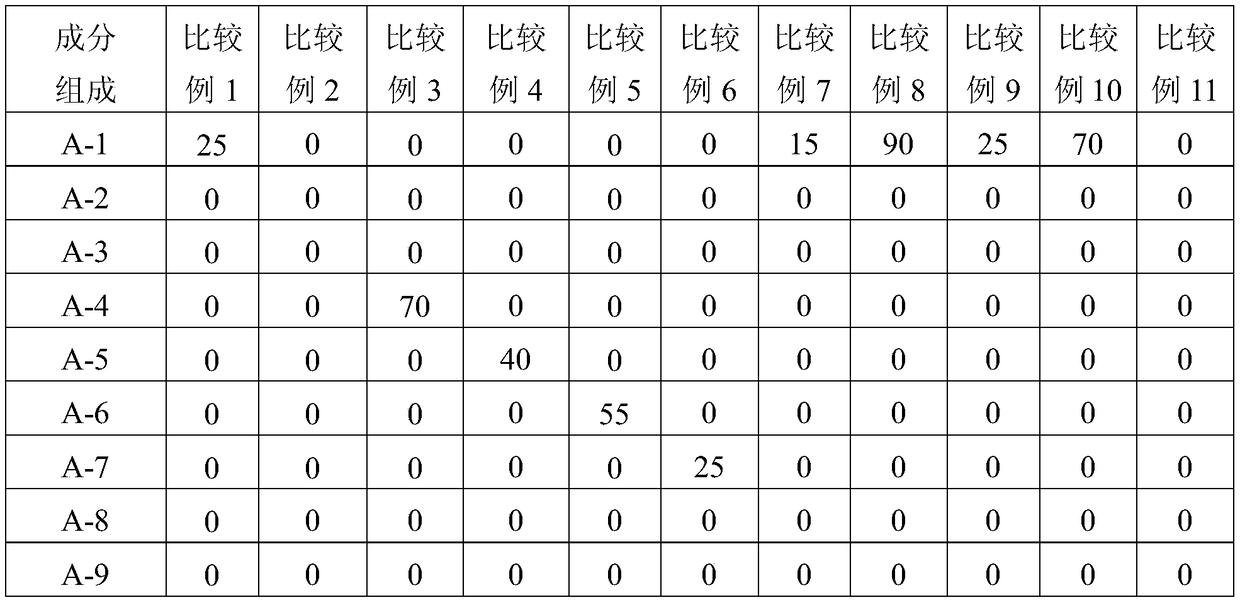

[0063] Concrete components and component contents of the resin compositions of Table 2 Comparative Examples 1 to 11

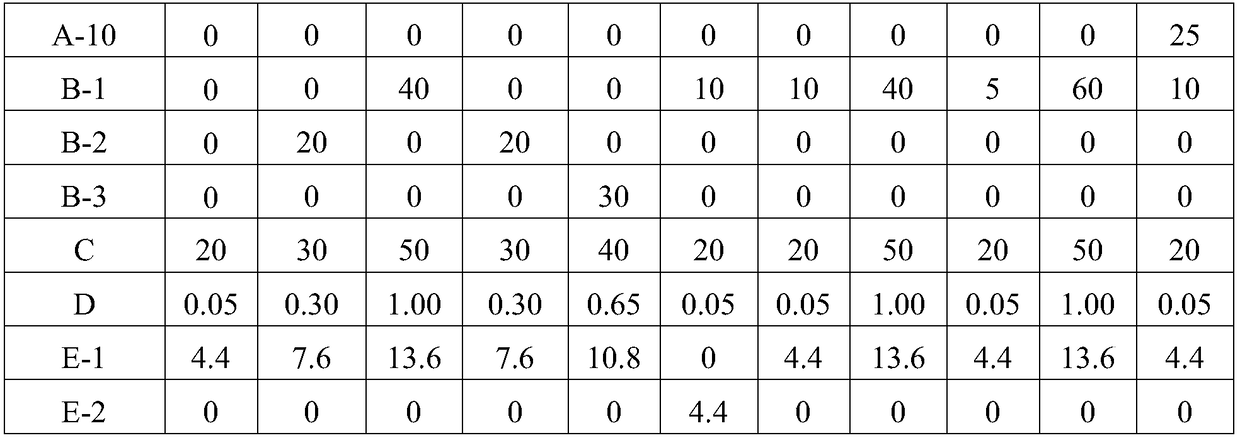

[0064]

[0065]

[0066] Each component code and its corresponding component name in Table 1 and Table 2 are as follows:

[0067] A Flame-retardant epoxy resin: Among them, the weight ratio of phosphorus-containing epoxy resin, brominated epoxy resin and nitrogen-containing epoxy resin in A-1~A-3 is (1.3:1.5:1); A-8 The weight ratio in A-9 is (1.5:1.75:1.2); the weight ratio in A-9 is (1.4:1.6:1.1); the weight ratio in A-10 is (0.8:2.5:0.5);

[0068] A-1: A combination of DOPO-based epoxy resin with a phosphorus content of 3%, BPA epoxy resin with a bromine cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com