Flame-retardant PP (polypropylene) composite material and preparation method thereof

A flame retardant composite material, polypropylene technology, applied in the field of plastics, can solve the problem of high cost of flame retardant polypropylene, and achieve the effects of improving the flame retardant effect, broadening the application field and high self-cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

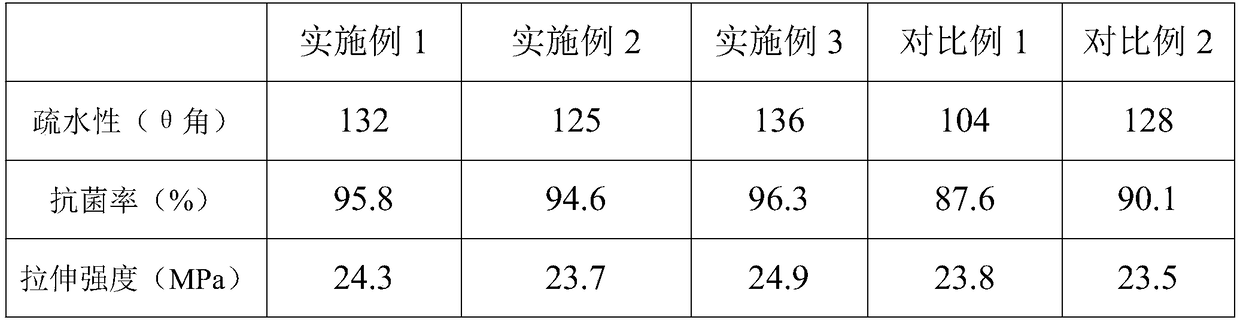

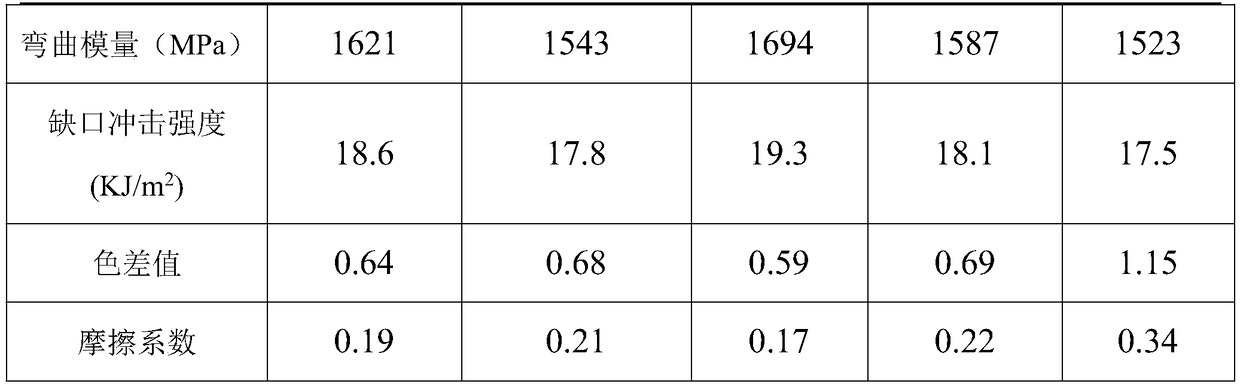

Examples

Embodiment 1

[0021] A polypropylene flame-retardant composite material, calculated in parts by weight, includes the following components:

[0022] 60 parts of polypropylene copolymer, 19 parts of wollastonite, 7 parts of magnesium aluminum hydrotalcite, 2 parts of phosphomolybdic acid, 5 parts of nano-zinc oxide modified by silane coupling agent, 7 parts of silicone rubber, isopropyl tri(dioctyl 2 parts of phosphoric acyloxy) titanate, 8 parts of ethylene-octene copolymer, 0.5 part of tris(2,4-di-tert-butylphenyl) phosphite and 1 part of polyethylene wax.

[0023] Preparation:

[0024] 1) First mix wollastonite, silicone rubber, isopropyl tris(dioctyl phosphate acyloxy) titanate, copolymerized polypropylene accounting for 35% of the total mass and toughening agent accounting for 15% of the total mass, Prepare the masterbatch with an internal mixer;

[0025] 2) Combine the masterbatch obtained in step 1) with magnesium aluminum hydrotalcite, phosphomolybdic acid, silane coupling agent mod...

Embodiment 2

[0027] A polypropylene flame-retardant composite material, calculated in parts by weight, includes the following components:

[0028] 55 parts of homopolypropylene, 15 parts of wollastonite, 10 parts of magnesium aluminum hydrotalcite, 1 part of phosphomolybdic acid, 3 parts of nano zinc oxide modified by silane coupling agent, 10 parts of silicone rubber, triisostearate titanic acid 1 part of isopropyl ester, 5 parts of ethylene-α-olefin polymer, 0.2 part of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 0.5 part of polyethylene wax.

[0029] Preparation:

[0030] 1) First mix wollastonite, silicone rubber, isopropyl titanate triisostearate, homopolypropylene accounting for 30% of the total mass and ethylene-α-olefin polymer accounting for 20% of the total mass, and use The internal mixer is discharged to prepare the masterbatch;

[0031] 2) Combine the masterbatch obtained in step 1) with magnesium aluminum hydrotalcite, phosphomolybdi...

Embodiment 3

[0033] A polypropylene flame-retardant composite material, calculated in parts by weight, includes the following components:

[0034] 35 parts of copolymerized polypropylene, 30 parts of homopolypropylene, 25 parts of wollastonite, 5 parts of magnesium aluminum hydrotalcite, 3 parts of phosphomolybdic acid, 6 parts of nano-zinc oxide modified by silane coupling agent, 5 parts of silicone rubber, iso 3 parts of propyl tris(dioctyl phosphate acyloxy) titanate, 10 parts of ethylene-octene copolymer, 0.8 parts of dioctadecyl thiodipropionate and 1.5 parts of polyethylene wax.

[0035] Preparation:

[0036] 1) Wollastonite, silicone rubber, isopropyl tri(dioctyl phosphate acyloxy) titanate, polypropylene resin accounting for 40% of the total mass and ethylene-octene copolymer accounting for 10% of the total mass Mix evenly, and prepare masterbatch with internal mixer;

[0037] 2) Combine the masterbatch obtained in step 1) with magnesium aluminum hydrotalcite, phosphomolybdic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com