Anti-wrinkle silver reflecting film and processing technology thereof

A processing technology and anti-wrinkle technology, applied in the field of functional films, can solve the problems of low reflective reflection efficiency, easy wrinkling of silver reflective films, and poor film adhesion, so as to avoid film separation, strong adhesion, and avoid direct effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

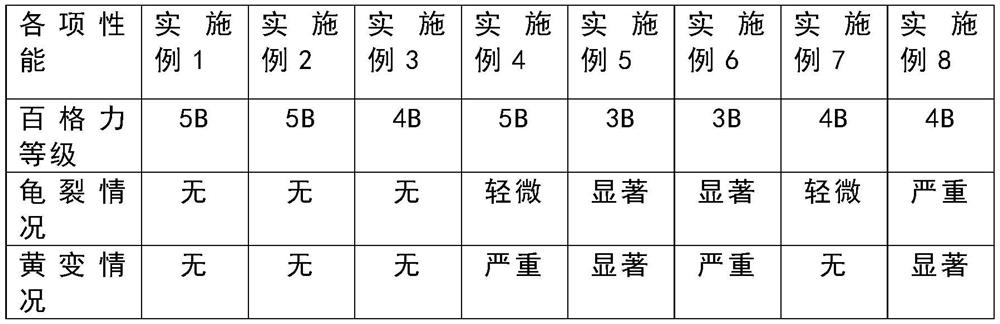

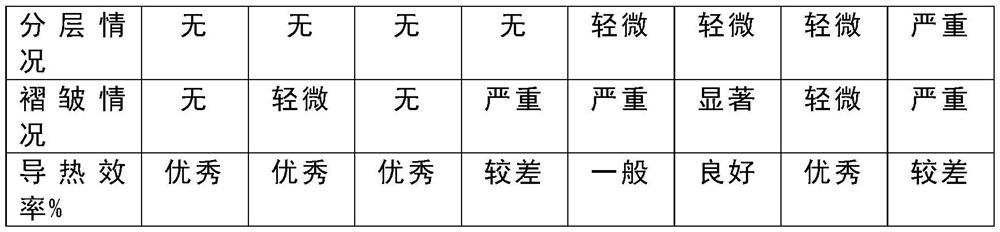

Examples

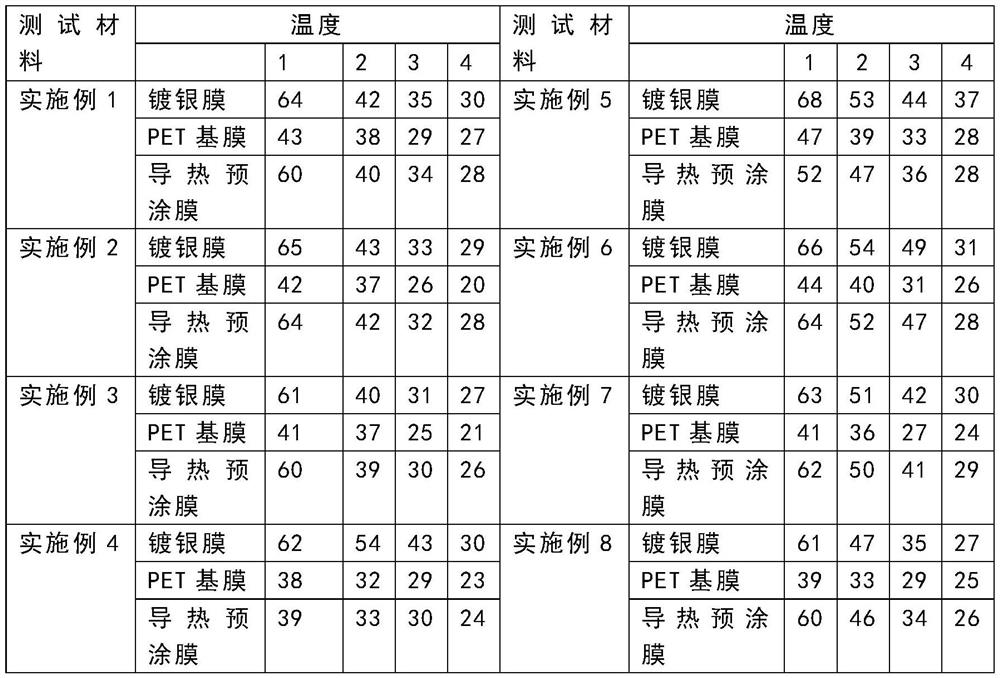

Embodiment 1

[0041] S1 preparation of thermally conductive coating:

[0042] a) Heat conduction powder pretreatment: Mix heat conduction powder A and heat conduction powder B evenly to obtain heat conduction powder mixture, pour the solvent into the heat conduction powder mixture and soak for 2 hours, disperse at 1500r / min for 900min, and put it into a three-roll mill for grinding Three steps to prepare a thermally conductive paste with a fineness of 10um;

[0043] b) Synthetic heat-conducting coating: mix anti-oxidant aging additive, polyurethane resin and solvent, stir at 500r / min for 90min, add heat-conducting slurry, stir at 300r / min for 40min, then stir at 1500r / min for 90min, Filtration to obtain a thermally conductive coating;

[0044] S2 Preparation of thermally conductive pre-coating film: at 90°C, evenly coat the thermally conductive coating on the surface of the PET film at a coating speed of 50m / min, and the coating amount of the thermally conductive coating on the upper surfa...

Embodiment 2

[0048] S1 preparation of thermally conductive coating:

[0049] a) Heat conduction powder pretreatment: mix heat conduction powder A and heat conduction powder B evenly to obtain heat conduction powder mixture, pour the solvent into the heat conduction powder mixture and soak for 2 hours, disperse at 2500r / min for 100min, and put it into a three-roll mill for grinding Three steps to prepare a thermally conductive paste with a fineness of 15um;

[0050] b) Synthetic heat-conducting coating: add anti-oxidant aging additive, polyurethane resin and solvent into the mixture respectively, stir at 500r / min for 100min, add heat-conducting slurry, stir at 400r / min for 50min, and then stir at 1500r / min Stir at a rotating speed for 110 minutes, filter to obtain a thermally conductive coating;

[0051] S2 Preparation of thermally conductive pre-coating film: at 110°C, evenly coat the thermally conductive coating on the surface of the PET film at a coating speed of 50m / min, and the coatin...

Embodiment 3

[0055] S1 preparation of thermally conductive coating:

[0056] a) Heat conduction powder pretreatment: mix heat conduction powder A and heat conduction powder B evenly to obtain heat conduction powder mixture, pour the solvent into the heat conduction powder mixture and soak for 2 hours, disperse at 3000r / min for 120min, and put it into a three-roller grinder for grinding Three steps to prepare a thermally conductive paste with a fineness of 20um;

[0057] b) Synthetic heat-conducting coating: mix anti-oxidant aging additive, polyurethane resin and solvent, stir at 500r / min for 120min, add heat-conducting slurry, stir at 500r / min for 60min, then stir at 1500r / min for 120min, Filtration to obtain a thermally conductive coating;

[0058] S2 Preparation of thermally conductive pre-coating film: at 140°C, evenly coat the thermally conductive coating on the surface of the PET film at a coating speed of 50m / min, and the coating amount of the thermally conductive coating on the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com