Halogen antimony-free resin composition, as well as prepreg, laminate and printed circuit board using same

A technology of resin composition and prepreg, which is applied in the field of halogen-free antimony-free resin composition, laminated board and printed circuit board, and prepreg, which can solve the problem of poor acid and alkali resistance of calcium carbonate, which needs to be further improved, and affects the board Processability and other problems to achieve the effect of making up for brittleness, low reactivity and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8 and comparative example 1~14

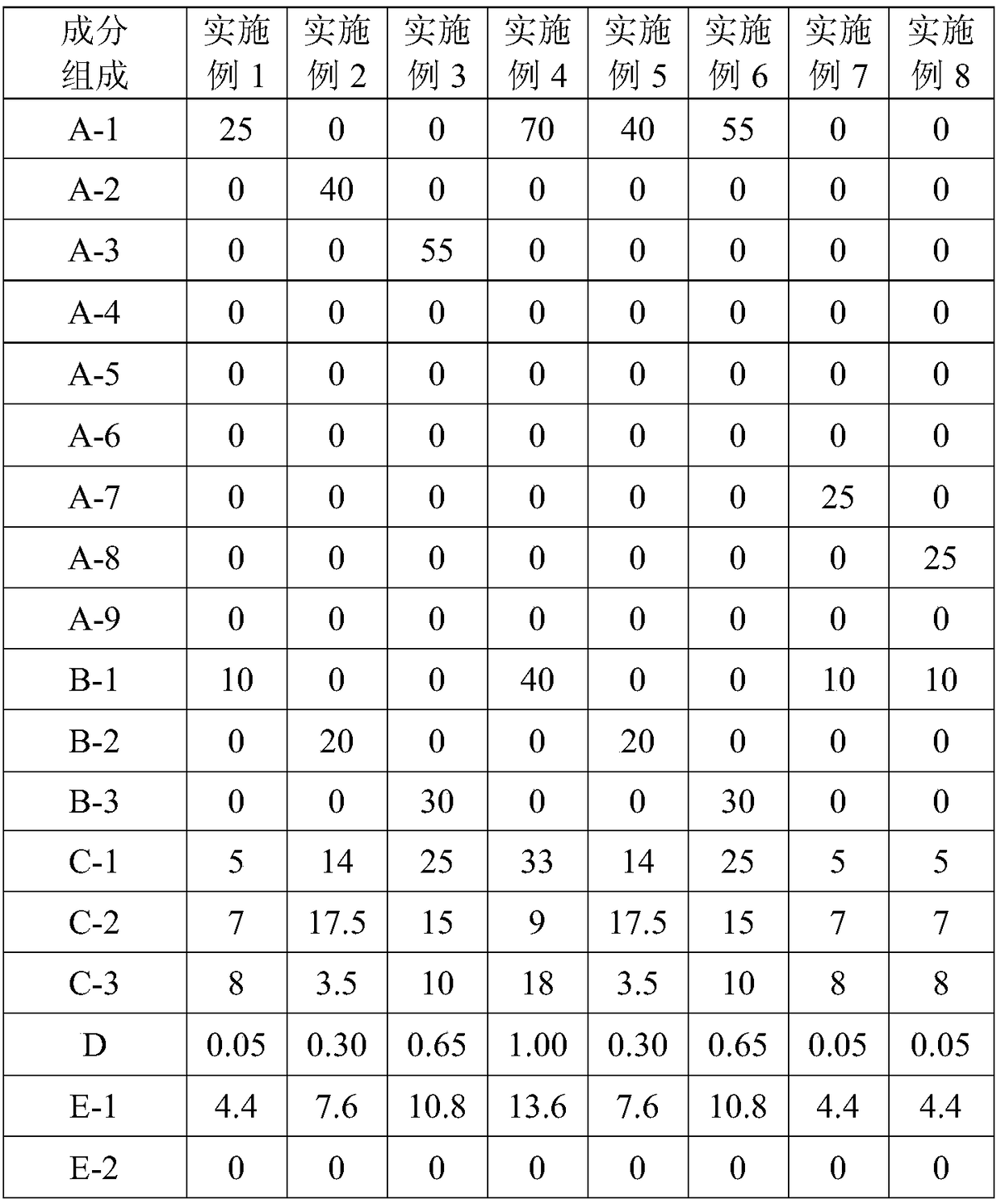

[0068] The specific components and component contents (in parts by weight) of the resin compositions of Examples 1 to 8 and Comparative Examples 1 to 14 are shown in Table 1 and Table 2.

[0069] Specific components and component contents of the resin compositions of Table 1 Examples 1-8

[0070]

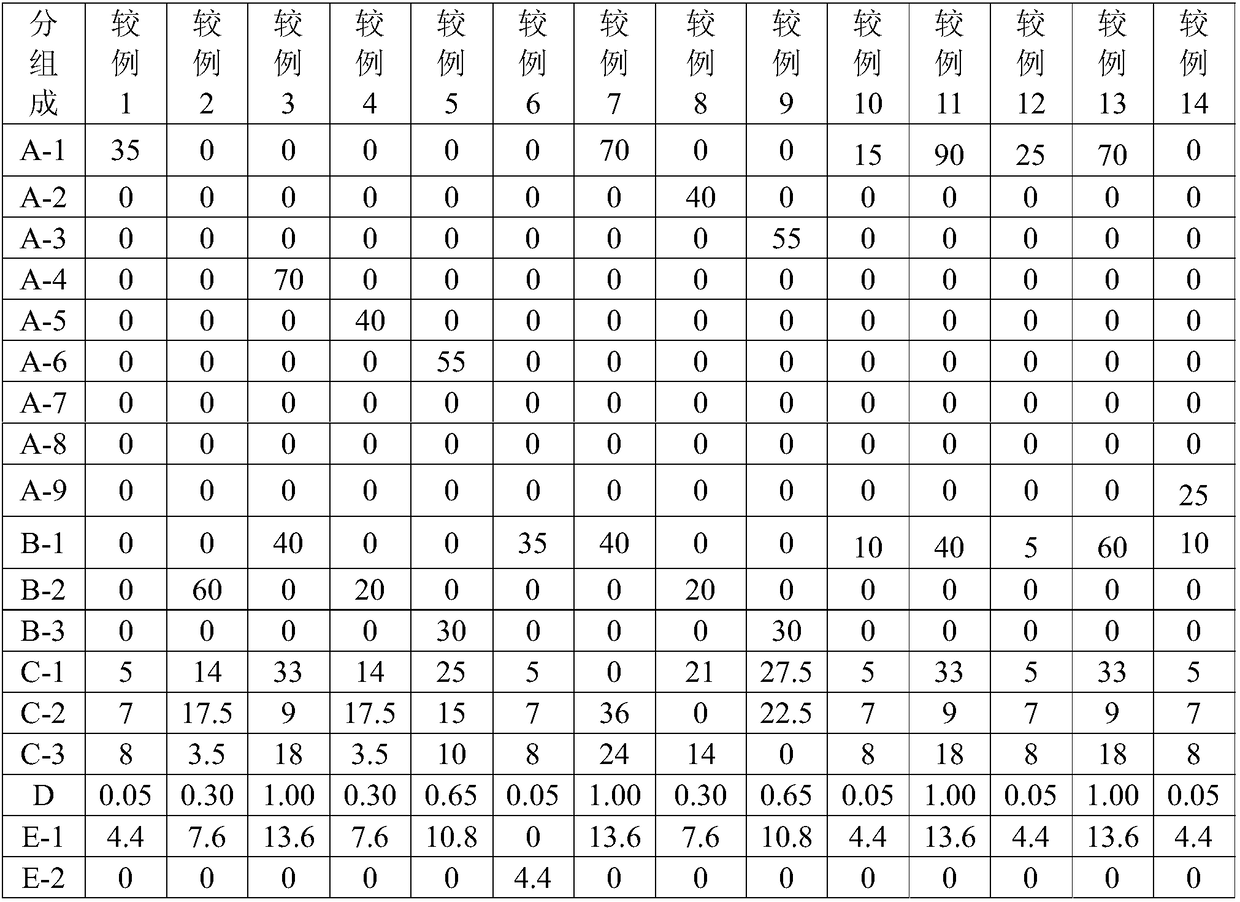

[0071] Table 2 Specific components and component contents of the resin compositions of Comparative Examples 1 to 14

[0072]

[0073]

[0074] The component codes and their corresponding component names in Tables 1 and 2 are as follows:

[0075] A flame retardant epoxy resin: wherein, the weight ratio of phosphorus-containing epoxy resin, brominated epoxy resin and nitrogen-containing epoxy resin in A-1 to A-3 is (1.3:1.5:1); A-7 The weight ratio in A-8 is (1.5:1.75:1.2); the weight ratio in A-8 is (1.4:1.6:1.1); the weight ratio in A-9 is (0.8:2.5:0.5);

[0076] A-1 Combination of DOPO-based epoxy resin with 3% phosphorus content, BPA epoxy resin with bromine content of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com