Halogen-free flame-retardant polypropylene material and preparation method thereof

A flame retardant polypropylene and polypropylene technology, applied in the field of polypropylene materials, can solve the problems of maintaining rigidity and toughness, greatly affecting product performance, and adding a large proportion of halogen-free flame retardants, reducing the amount of flame retardants, The effect of improving flame retardant effect and broad market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 15 parts of intumescent flame retardant; 3 parts of zirconium phosphate; 2 parts of expanded graphite; 1 part of hindered phenolic heat stabilizer; 0.5 part of white oil 36#; After mixing evenly, add it to a twin-screw extruder with a length-to-diameter ratio of 38:1 to obtain the product through melting, extrusion, and granulation.

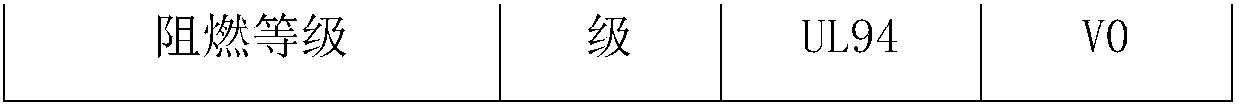

[0028] The performance of the above products are as follows:

[0029] performance

Embodiment 2

[0031] 12 parts of intumescent flame retardant; 4 parts of zirconium phosphate; 1.5 parts of expanded graphite; 1.5 parts of hindered phenolic heat stabilizer; 0.6 part of white oil 36#; After uniformity, it is added to a twin-screw extruder with a length-to-diameter ratio of 36:1 to obtain the product through melting, extrusion, and granulation.

[0032] The performance of the above products is as follows:

[0033] performance

Embodiment 3

[0035] 18 parts of intumescent flame retardant; 4 parts of zirconium phosphate; 2.5 parts of expanded graphite; 0.8 part of hindered phenolic heat stabilizer; 0.2 part of white oil 72#; 74.5 parts of polypropylene PP EA5074 (Basel) were weighed in proportion After mixing evenly, add it to a twin-screw extruder with a length-to-diameter ratio of 40:1 to obtain the product through melting, extrusion, and granulation.

[0036] The performance of the above products is as follows:

[0037]

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com