Synergistic flame-retardant polyether polyol for sponge and preparation method thereof

A technology of polyether polyol and synergistic flame retardant, which is applied in the field of synergistic flame retardant sponge polyether polyol and its preparation, can solve the problem of unconsidered polyether polyol flame retardant effect, general flame retardant effect, flame retardant Precipitation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

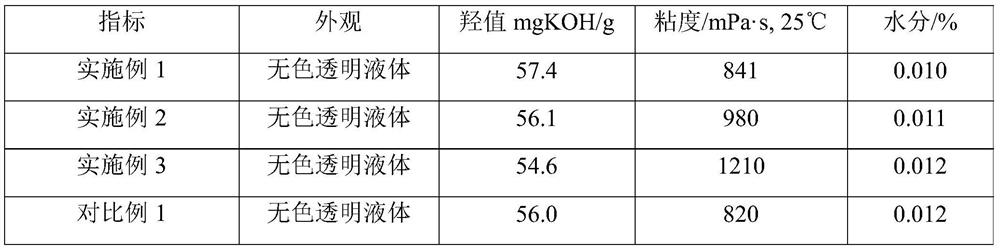

Embodiment 1

[0033] Add 471.6g of tris(2-hydroxyethyl)isocyanurate, 67.6g of polyphosphoric acid, and 1.28g of double metal cyanide complex catalyst into the reactor at room temperature, and dehydrate under vacuum at -0.093MPa and 100°C 2h; raise the temperature to 120°C, add 80.8g of propylene oxide to induce the activation reaction, when the pressure in the reaction device continues to drop to negative pressure and the temperature continues to rise, it indicates that the polymerization reaction has started, and continuously feed 4820g of propylene oxide and ethylene oxide Alkane 960g, reaction temperature 130°C; after feeding, continue aging reaction for 1h, then vacuum degassing at -0.093MPa for 1h, cool down to 80°C and discharge, to obtain polyether polyol for synergistic flame-retardant sponge.

Embodiment 2

[0035] Add 91.7g of tris(2-hydroxyethyl)isocyanurate, 50.7g of polyphosphoric acid, and 0.195g of double metal cyanide complex catalyst into the reactor at room temperature, and dehydrate under vacuum at -0.093MPa and 120°C 1h; raise the temperature to 140°C, add 14.2g of propylene oxide to induce the activation reaction, when the pressure in the reaction device continues to drop to negative pressure and the temperature continues to rise, it indicates that the polymerization reaction has started, and continuously feed 1601g of propylene oxide and ethylene oxide Alkane 195.3g, reaction temperature 140°C; after feeding, continue aging reaction for 0.5h, then vacuum degassing at -0.093MPa for 2h, cool down to 80°C and discharge to obtain polyether polyol for synergistic flame-retardant sponge.

Embodiment 3

[0037] Add 170.3g of tris(2-hydroxyethyl)isocyanurate, 219.7g of polyphosphoric acid, and 0.12g of double metal cyanide complex catalyst into the reactor at room temperature, and dehydrate under vacuum at -0.093MPa and 110°C 0.5h; raise the temperature to 130°C, add 19.5g of propylene oxide to induce the activation reaction, when the pressure in the reaction device continues to drop to negative pressure and the temperature continues to rise, it indicates that the polymerization reaction has started, and continuously feed 5010g of propylene oxide and epoxy Ethane 602g, reaction temperature 150°C; after feeding, continue aging reaction for 1h, then vacuum degassing at -0.093MPa for 1.5h, cool down to 80°C and discharge to obtain polyether polyol for synergistic flame-retardant sponge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com