Ceramic diaphragm and preparation method and application thereof, and battery comprising ceramic diaphragm

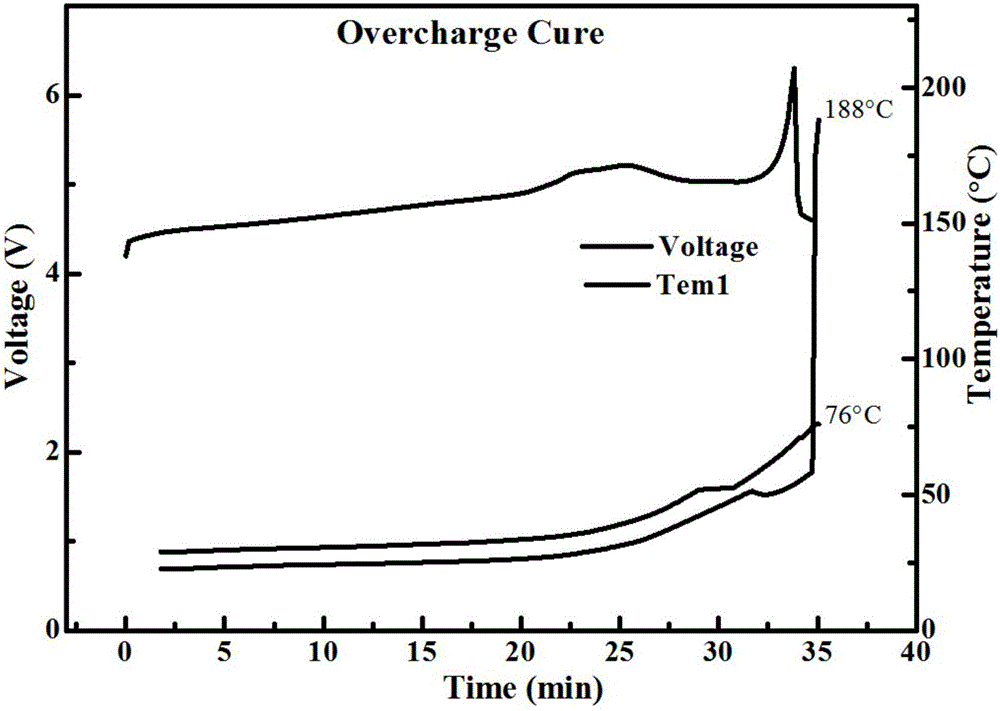

A ceramic diaphragm and ceramic powder technology, applied in the field of electrochemistry, can solve the problems of battery combustion and explosion accidents, the diaphragm cannot provide electronic conductive partitions, and the flame retardant performance cannot provide sufficient insulation guarantees, so as to increase safety, Strong popularization and application value, the effect of stable flame retardant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

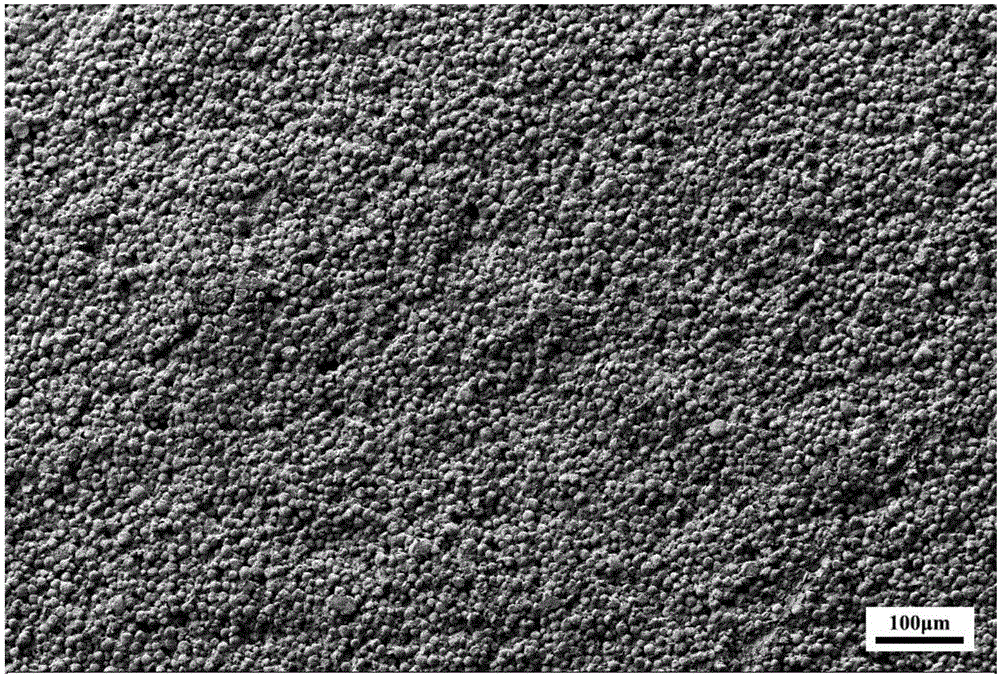

[0025] Preparation method: first mix 9wt% cerium oxide powder and 80wt% zirconia powder together to form a ceramic powder, then weigh 3wt% polyethylene glycol and dissolve it in an ethanol solution, stir and dissolve it fully, and pour it into The mixed ceramic powder is added, after being stirred at a high speed of 1500rpm in the mixer for 2 hours, the secondary granulation is carried out by spray drying method, and the spray dried powder is calcined at 900°C for 4h, and the heating rate is set at 10°C / min; then mix 11wt% of the binder polyvinylpyrrolidone and a certain amount of nitrogen methylpyrrolidone solution, and add the calcined ceramic powder after the dispersion is uniform, and after high-speed stirring, the ceramics are coated on the polyolefin micropores On the membrane, both sides are coated with a thickness of 10 μm respectively.

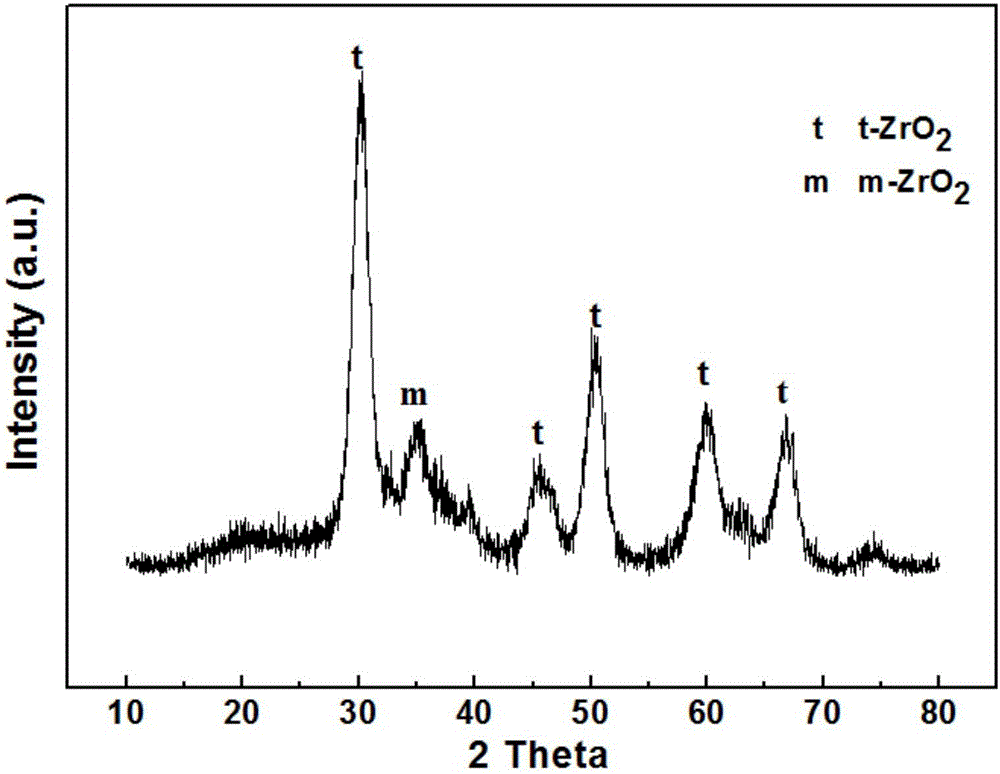

[0026] from figure 1 It can be seen that the crystal form of zirconia doped with 9wt% ceria is mostly tetragonal, that is, tetrago...

Embodiment 2

[0030] Preparation method: first mix 20wt% hafnium oxide powder and 75wt% zirconium oxide powder together to form a ceramic powder, then weigh 3wt% polyvinylpyrrolidone and dissolve it in ethanol solution, stir and dissolve fully, pour into it Add the mixed ceramic powder, after stirring at a high speed of 1200rpm for 2 hours, use the spray drying method for secondary granulation, and calcinate the spray-dried powder at 930°C for 4h, and set the heating rate to 10°C / min; Binder 3wt% styrene-butadiene rubber, 2wt% sodium carboxymethyl cellulose and a certain amount of nitrogen methyl pyrrolidone solution are mixed, after the dispersion is uniform, the calcined ceramic powder is added, after high-speed stirring, the ceramics are coated on On a polyolefin microporous membrane, coated on one side, with a thickness of 30 μm.

[0031] from Figure 4 It can be seen that most of the zirconia after 20wt% hafnium oxide doping is tetragonal zirconia t-ZrO 2 .

Embodiment 3

[0033] Preparation method: first mix 3wt% yttrium oxide powder and 95wt% zirconia powder together to form a ceramic powder, then weigh 0.3wt% polyethylene glycol and dissolve it in ethanol solution, stir and dissolve, Add the mixed ceramic powder into it, after 1300rpm high-speed stirring for 1.5h, secondary granulation by spray drying method, and calcine the spray-dried powder at 920°C for 4h, set the heating rate to 10°C / min ; Then mix 2wt% binder polyvinyl alcohol and a certain amount of nitrogen methyl pyrrolidone solution, add the calcined ceramic powder after the dispersion is uniform, and after high-speed stirring, the ceramic is coated on the polyolefin microporous membrane , coated on both sides, with a thickness of 0.2 μm, respectively.

[0034] from Figure 5 It can be seen that the zirconia doped with 3wt% yttria is all tetragonal zirconia.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com