Novel mineral reflective thermal insulation coating for architecture and preparation method thereof

A reflective thermal insulation coating and construction technology, applied in reflective/signal coatings, coatings, etc., can solve problems such as fading of coating functions, and achieve the effect of preventing cracking, excellent performance and good environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) pulping

[0064] Add 178.0g of water, 2.0g of Natrosol 250MHR (purchased from Hercules, USA) to the dispersion tank in sequence, and stir until completely dissolved; (purchased from German Becker Gilini Company) 2.0g, Lopon ST (purchased from German Becker Gilini Company) 5.0g, continue to stir until uniform; then add titanium dioxide R-706 (purchased from DuPont Company) 150.0g, granules 100.0 g of heavy calcium with a diameter of 1.1 μm (purchased from Liaoning Haicheng Heshan Company), 40.0 g of heavy calcium with a particle size of 10 μm (purchased from Liaoning Haicheng Heshan Company), and wollastonite with a particle size of 12 μm (purchased From Jilin Lishu Wollastonite Co., Ltd.) 60.0g in the mixed solution; after adding, use 15.0g of reserved water to wash the material sticking to the dispersion shaft and the cylinder wall into the cylinder; the stirring speed is 1400-2000 rpm Disperse at high speed for 18 minutes under the condition of 1 minute.

[0065...

Embodiment 2

[0070] (1) pulping

[0071] Add 185.6g of water and 2.4g of hydroxyethyl cellulose (purchased from Clariant, Germany) with a viscosity of HS 30000yp into the dispersion tank in turn, and stir until completely dissolved; then add Inocot610 (purchased from Van White Soft Silicate Products Company) 2.0g, Lopon 895 (purchased from German Becker Gilini Company) 2.0g, Lopon ST (purchased from German Becker Gilini Company) 5.0g, continue to stir until uniform; then add titanium dioxide CR-501 (purchased from Jinzhou Titanium Dioxide Co., Ltd.) 120.0g of calcite with a particle size of 0.7μm (purchased from Liaoning Haicheng Heshan Company) 150.0g of calcite with a particle size of 5μm (purchased from Liaoning Haicheng Heshan Company) 77.0g, particle size 1g of 38μm mica powder (purchased from Chuzhou Gerui Company) was added to the mixed solution; after adding, 10.0g of reserved water was used to wash the material sticking to the dispersion shaft and the cylinder wall into the cylind...

Embodiment 3

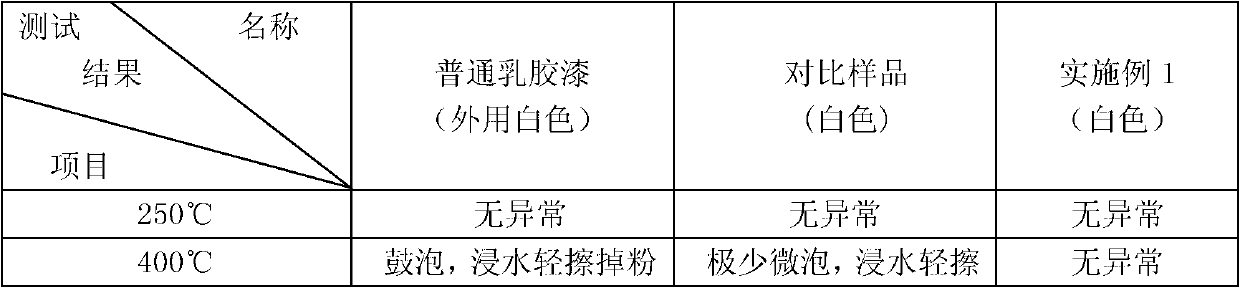

[0076] Embodiment 3 coating performance test

[0077] The China Academy of Building Research and the China Academy of Space Technology jointly tested Embodiment 1, and the results are shown in Table 3. All performances of Embodiment 1 are better than national technical indicators.

[0078] table 3

[0079]

[0080]

[0081] The coating prepared in the pilot test of the formula of Example 1 is used in the X-ray perspective room of Xinglongtai District Center for Disease Control and Prevention, Panjin City. The building is 15.24 meters long, 4.64 meters wide and 3.2 meters high. The roof is made of dark blue curved color steel plate, and the facade is made of light gray old latex paint. The total painting area of the top and the facade is about 260m2 2 . Roller coating is used for construction, first brush the sealing primer one coat, and after drying (about 20 minutes), roll coat the pilot product according to the formula in Example 1 once, and roll coat the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com