Thermosetting resin composition, prepreg using thermosetting resin composition, laminated board and printed circuit board

A resin composition and thermosetting technology, applied in the fields of prepreg, thermosetting resin composition, laminate and printed circuit board, can solve the problems of not being able to use, not pointing out, not using copper clad laminates, etc., and achieving low Water absorption rate and effect of improving flame retardancy

Active Publication Date: 2020-02-28

SHAANXI SHENGYI TECH

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the flame retardant of halogenated CEM-1 copper-clad laminates is mainly realized by the traditional halogen-antimony synergistic flame-retardant technology. However, with the continuous tightening of environmental management substances, antimony oxide substances are being considered by the European Union to be included in RoHS restrictions The list of substances, once restrictions are implemented in the future, the halogen antimony synergistic flame retardant technology will not be used, so new technologies must be developed to replace traditional technologies

[0003] CN103073744A provides a kind of phosphorus-nitrogen-bromine composite system flame retardant, whi

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Login to View More

Abstract

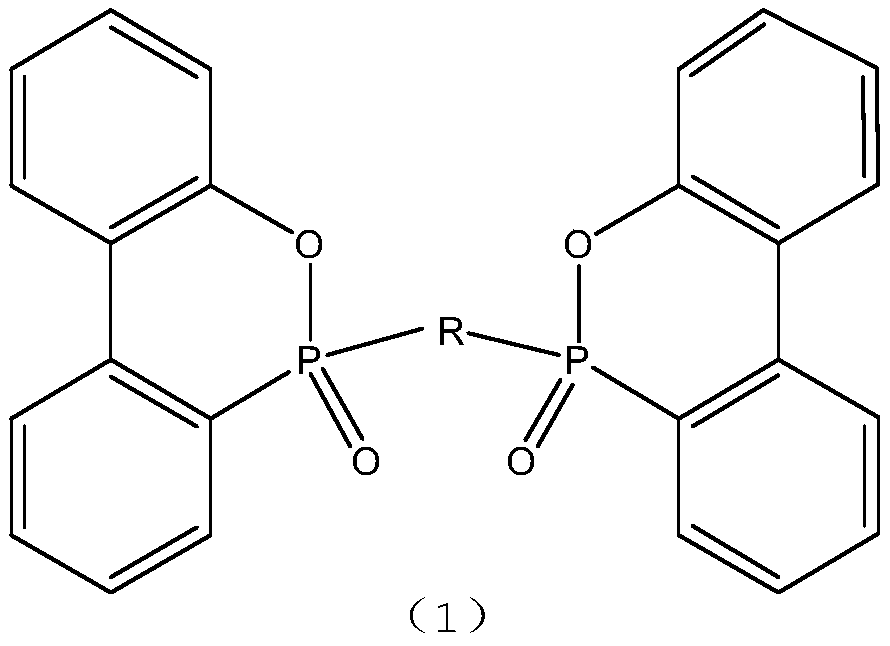

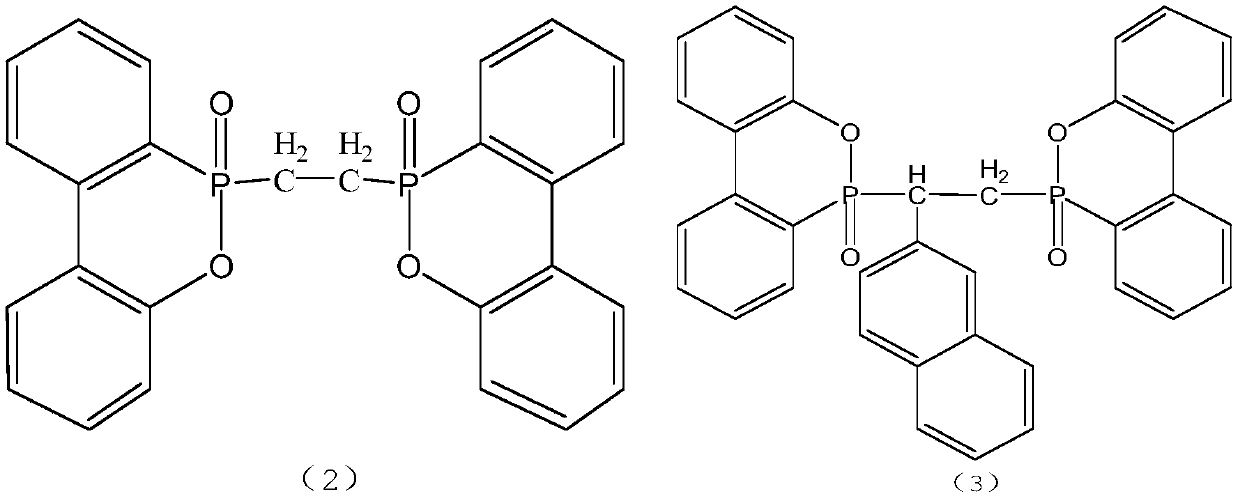

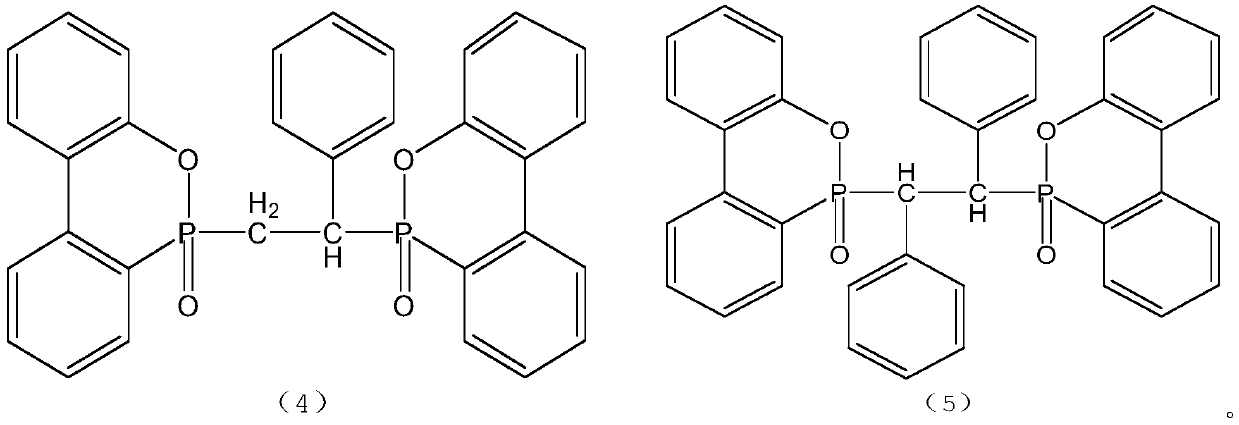

The invention provides a thermosetting resin composition, a prepreg using the thermosetting resin composition, a laminated board and a printed circuit board. The thermosetting resin composition comprises epoxy resin, a curing agent, a curing accelerator and a composite flame-retardant filler, wherein the composite flame-retardant filler comprises a DOPO derivative, a melamine salt compound and a metal hydroxide; the DOPO derivative has a structure as shown in a formula (1). Through cooperation of the DOPO derivative, the melamine salt compound and the metal hydroxide in the composite flame-retardant filler, the flame retardance of a cured product can be effectively improved, and the cured product can have good heat resistance and dip soldering resistance and low water absorption.

Description

Technical field [0001] The invention belongs to the technical field of laminates, and relates to a thermosetting resin composition, a prepreg using the same, a laminate and a printed circuit board. Background technique [0002] CEM-1 copper clad laminate is made of electronic grade glass fiber cloth and bleached wood pulp paper as reinforcement materials, respectively impregnated with a resin composition for copper clad laminate to make fabric and core material, and covered with copper foil. It is made by hot pressing. Flame retardancy is one of the most concerned properties of CEM-1 copper clad laminate, but CEM-1 copper clad laminate is based on wood pulp paper bonding sheet as the core material. The wood pulp paper itself is combustible. -1 Under the premise of other properties of copper clad laminates, especially heat resistance, toughness, and moisture resistance, it is very difficult to improve the flame retardancy of CEM-1 copper clad laminates. At present, the flame ret...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08G59/62C08K5/3492C08K3/22C08K5/5313C08K5/03C08J5/24B32B15/09B32B27/04B32B33/00

CPCC08G59/621C08K5/34928C08K3/22C08K5/5313C08K3/2279C08K5/03C08J5/24B32B15/092B32B33/00C08J2363/00C08K2003/2224C08K2003/2227B32B2307/3065B32B2363/00B32B2260/046

Inventor 张龙李莎

Owner SHAANXI SHENGYI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com