Resin composition and preparation method thereof

A technology of resin composition and epoxy resin, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of high brittleness of cured products, unsatisfactory bismaleimide performance, limitations, etc. problems, to achieve the effect of improving processing operability, good solubility, and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the present embodiment, the preparation method of resin composition comprises the following steps in sequence:

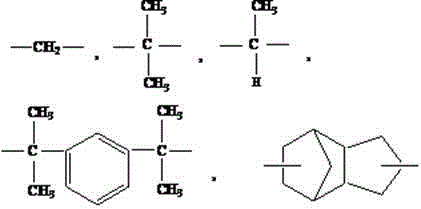

[0026] (1) By weight, 100 parts of 4,4′-diphenylmethane bismaleimide, 43 parts of 2,2′-diallyl bisphenol A and 150 parts of N,N′-dimethyl Formamide is added to the reaction kettle with a stirrer, condenser and thermometer, the stirrer is stirred at a speed of 280 rpm and heated to 130-135°C; then a constant temperature of 130-135°C is maintained, and the stirrer is Stir at a speed of 280 rpm, react for 32 minutes; then stop heating and continue stirring, stop stirring after the temperature of the material in the reactor drops to 23°C, and obtain a modified bismaleimide product;

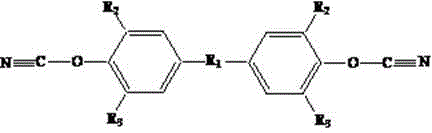

[0027] (2) Add 258.6 parts of bisphenol A type cyanate, 0.248 parts of cobalt acetylacetonate, 10.24 parts of 4-nonylphenol, 116 parts of N,N′-dimethylformamide and 114 parts of cyclohexanone into the step ( 1) In the obtained modified bismaleimide product, the stirrer was stirred ...

Embodiment 2

[0029] In the present embodiment, the preparation method of resin composition comprises the following steps in sequence:

[0030] (1) By weight, add 100 parts of 4,4'-diphenylmethane bismaleimide, 6.85 parts of diallyl ether and 150 parts of N,N'-dimethylformamide into the mixer with agitator , condensing tube and thermometer, the stirrer is stirred at a speed of 300 rpm and heated to 130-135°C; then a constant temperature of 130-135°C is maintained, and the stirrer is stirred at a speed of 300 rpm , and reacted for 30 minutes; then stop heating and continue to stir, and stop stirring after the temperature of the material in the reactor drops to 23° C. to obtain a modified bismaleimide product;

[0031] (2) Add 103.3 parts of dicyclopentadiene cyanate, 0.015 parts of zinc isooctanoate, 2.96 parts of 4-cinnamon phenol and 82 parts of N,N'-dimethylformamide to the modified product obtained in step (1). In the bismaleimide product, the stirrer stirred for 30 minutes at a speed o...

Embodiment 3

[0033] In the present embodiment, the preparation method of resin composition comprises the following steps in sequence:

[0034] (1) By weight, add 100 parts of N,N'-m-phenylene bismaleimide, 50 parts of 2-allylphenol and 150 parts of N,N'-dimethylformamide with stirring In the reactor, condenser and thermometer, the stirrer is stirred at a speed of 250 rpm and heated to 140-145°C; Stir and react for 35 minutes; then stop heating and continue to stir, and stop stirring after the temperature of the material in the reactor drops to 25°C to obtain a modified bismaleimide product;

[0035] (2) Add 259.4 parts of bisphenol A cyanate, 0.322 parts of cobalt isooctanoate, 9.89 parts of 4-cinnamon phenol, 140 parts of N,N'-dimethylformamide and 124 parts of acetone to step (1) to obtain In the modified bismaleimide product, the agitator stirred for 40 minutes at a speed of 1500 rpm; then added 81 parts of dicyclopentadiene phenolic epoxy resins, stirred for 30 minutes, and the stirri...

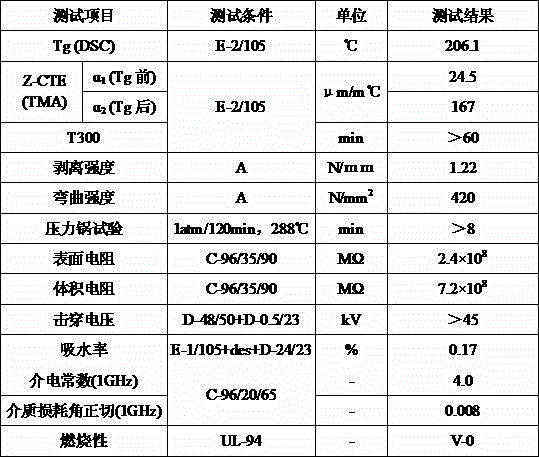

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com