Glue solution for copper-clad substrate, and preparation method thereof

A technology of copper-clad substrate and glue, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of heat resistance decline, low dielectric property flame retardancy, glass transition temperature reduction, etc. problem, to achieve the effect of low raw material cost and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

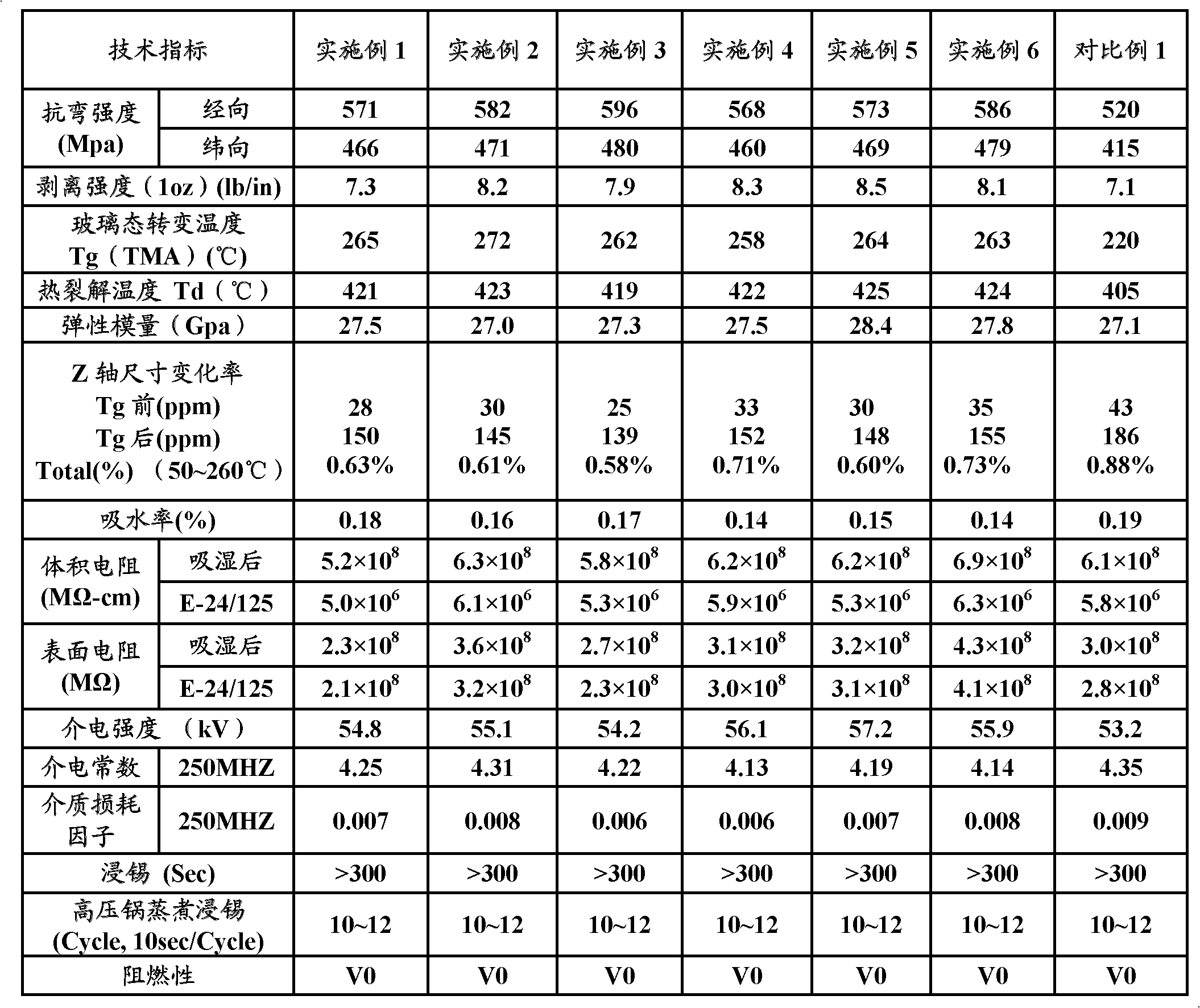

Examples

Embodiment 1

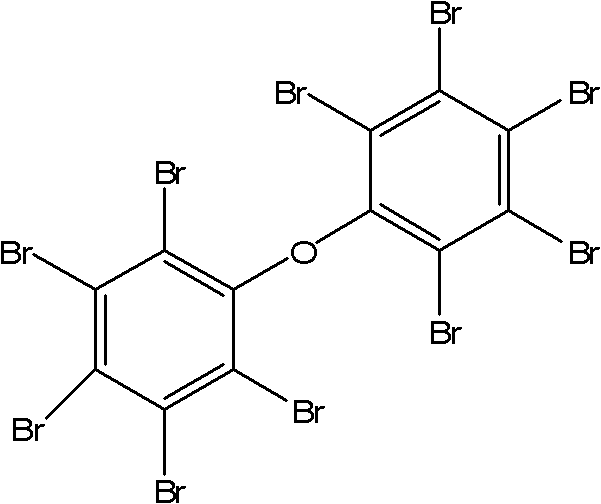

[0022] According to the glue solution of this embodiment, its raw material formula is as follows: 100g of 4,4'-diphenylmethane bismaleimide; 50g of diallyl bisphenol A; 30g of decabromodiphenyl ether; 2-methylimidazole 0.06g; aluminum hydroxide 10g; butanone 15g.

[0023] The preparation process of the glue is as follows: Take 100g of 4,4'-diphenylmethane bismaleimide and 50g of diallyl bisphenol A, put them into a 500ml container, and react at 130°C for about 60min, after cooling Add appropriate amount of butanone to dissolve. After the resin is completely dissolved, add 30g of decabromodiphenyl ether, 0.06g of 2-methylimidazole, 10g of aluminum hydroxide, and finally add the remaining amount of methyl ethyl ketone, and stir evenly to obtain the glue.

Embodiment 2

[0025] According to the glue solution of this embodiment, its raw material formula is as follows: 100 g of 4,4'-diphenyl ether bismaleimide; 50 g of diallyl bisphenol A; 20 g of decabromodiphenyl ether; 2-methylimidazole 0.06g; aluminum hydroxide 15g; butanone 15g.

[0026] The preparation process of the glue solution is as follows: Take 100g of 4,4'-diphenyl ether bismaleimide and 40g of diallyl bisphenol A, put them into a 500ml container, react at 130°C for 60min, and add after cooling Appropriate amount of methyl ethyl ketone dissolved. After the resin is completely dissolved, add 20g of decabromodiphenyl ether, 0.06g of 2-methylimidazole, 15g of aluminum hydroxide, and finally add the remaining methyl ethyl ketone, stir evenly to obtain the glue.

Embodiment 3

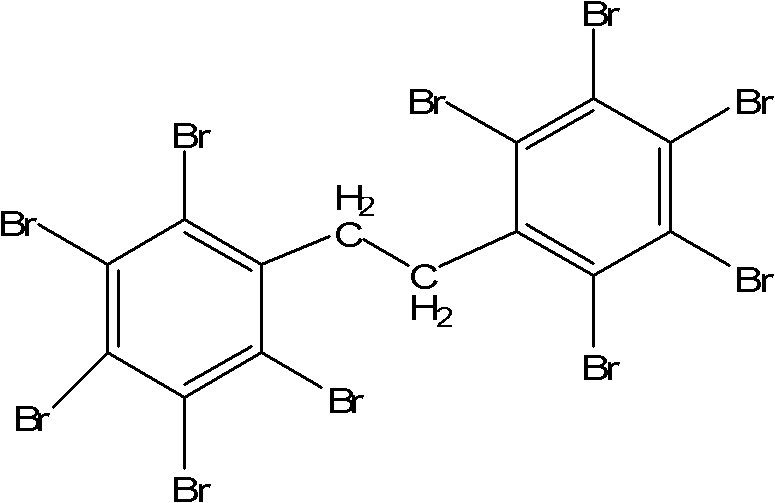

[0028] According to the glue solution of this embodiment, its raw material formula is as follows: 100g of 4,4'-diphenylisopropylbismaleimide; 60g of diallyl bisphenol A; 15g of decabromodiphenyl ether; 0.05 g of imidazole; 20 g of aluminum hydroxide; 15 g of butanone.

[0029] The preparation process of the glue solution is as follows: Take 100g of 4,4'-diphenylisopropylbismaleimide and 60g of diallyl bisphenol A, put them into a 500ml container, react at 130°C for 60min, and wait for cooling Then add appropriate amount of butanone to dissolve. After the resin is completely dissolved, add 15g of decabromodiphenylethane, 0.05g of 2-methylimidazole, 20g of aluminum hydroxide, and finally add the remaining methyl ethyl ketone, stir evenly to obtain the glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com