UV curable adhesive

An adhesive and photoinitiator technology, applied in the direction of adhesives, non-polymer organic compound adhesives, adhesive types, etc., can solve problems such as insufficient bonding performance

Active Publication Date: 2010-12-29

JIANGSU HECHENG ADVANCED MATERIALS

View PDF3 Cites 42 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The vinyl compounds in this type of adhesive are (meth)acrylate compounds, allyl compounds or vinyl compounds. For special substrates, especially inert substrates and metal oxide substrates such as polytetrafluoroethylene, indium oxide Tin (ITO), etc., but still does not provide sufficient bonding performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

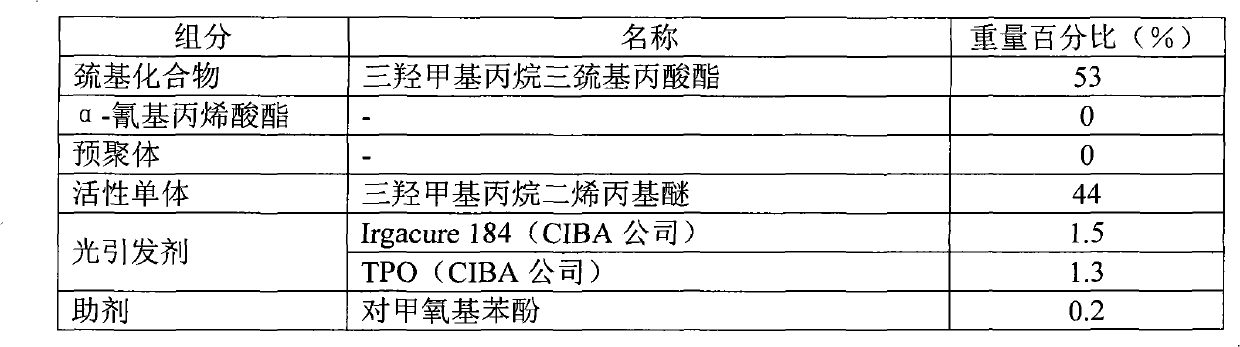

Embodiment 1

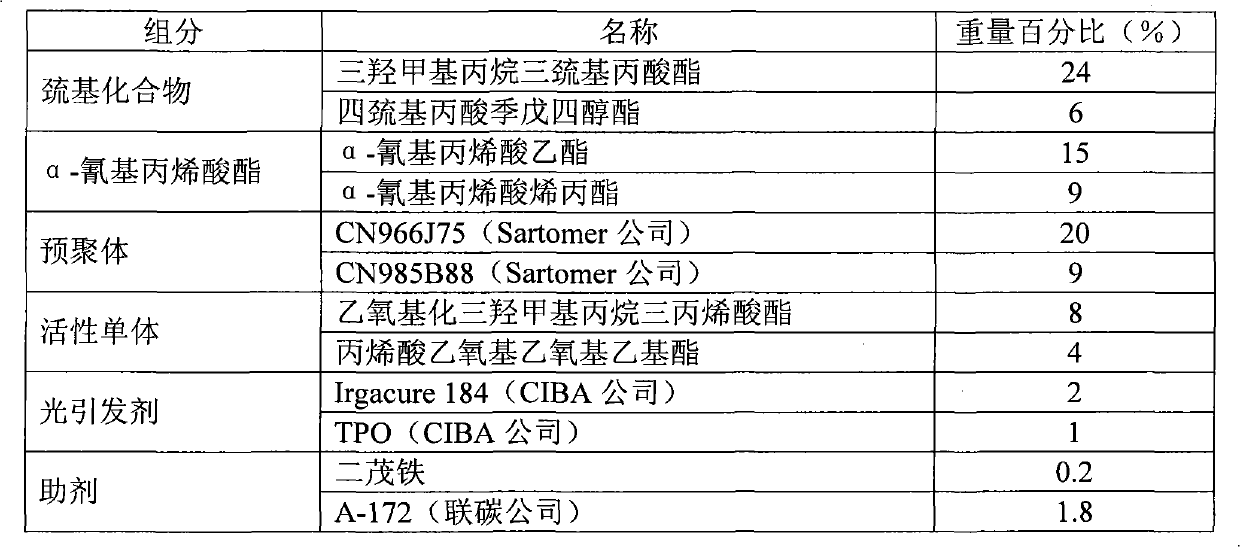

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

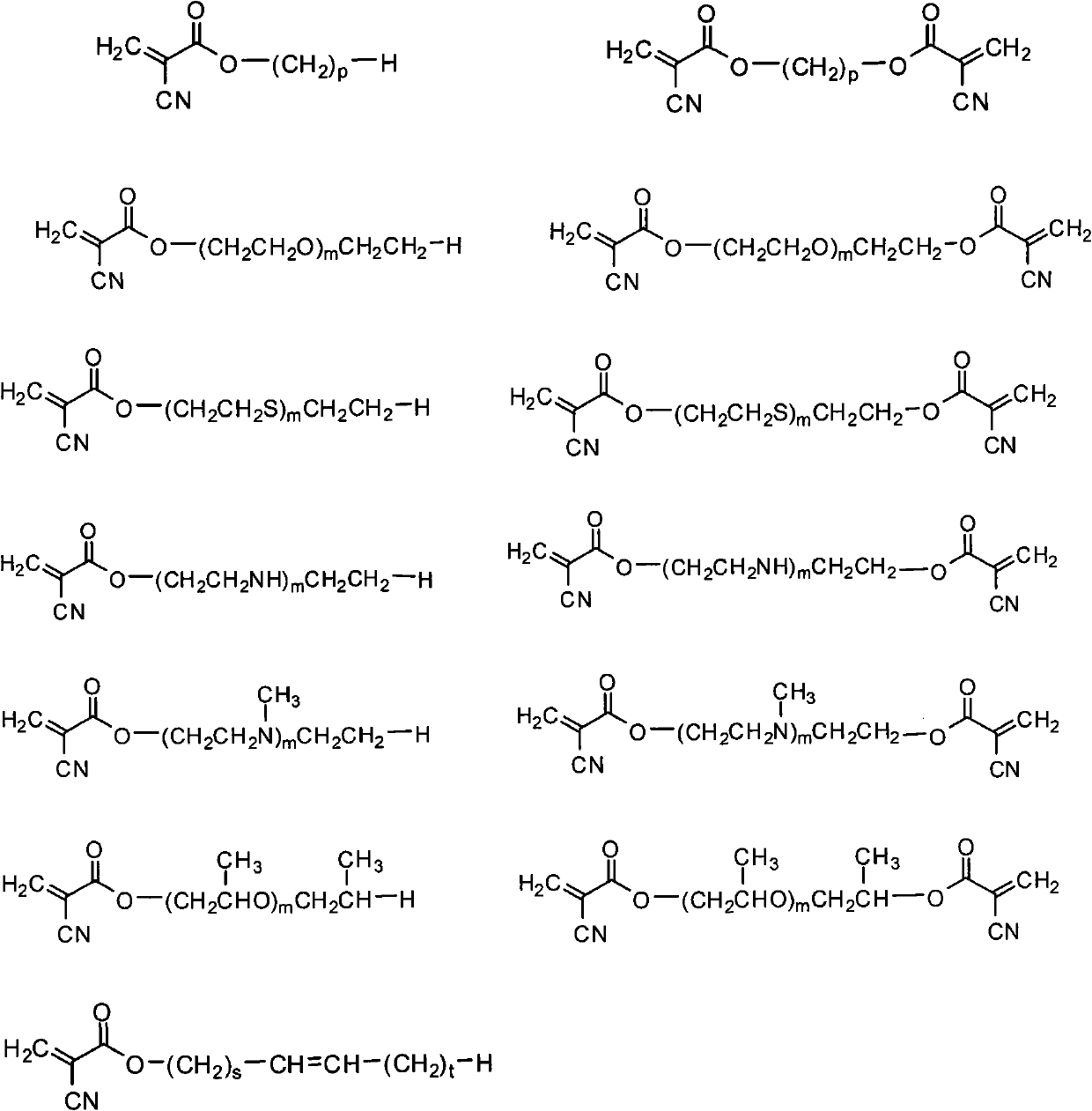

The invention discloses a sulfydryl / cyano acrylic ester UV curable adhesive composition, which comprises: 5 to 60 percent of sulfydryl compound which is selected from a sulfydryl alkyl acid ester and alkyl hydrosulfide; 5 to 60 percent of alpha-cyanoacrylate of a formula below; 0 to 60 percent of a prepolymer selected from polyester acrylate prepolymers, epoxy acrylate prepolymers and urethane acrylate prepolymers; 0 to 50 percent of active monomer which is selected from acrylic esters having a mono-functional group, double functional groups and multiple functional groups, allyl compounds and ethenyl compounds; 1 to 10 percent of photoinitiator; and 0 to 10 percent of assistant. The UV curable adhesive composition has a quick curing capability, high adhesive strength and low internal stress; and the obtained cured layer is flexible and can be widely to bond metal, metal oxides, plastics, rubber, glass, polyester and other substrate materials.

Description

technical field The invention relates to a UV photocurable adhesive, in particular to a UV photocurable adhesive comprising a polymerization system of a mercapto compound and a cyanoacrylate. Background technique Since the advent of UV light-curing adhesives in the 1960s, they have achieved rapid development and are widely used in various fields such as medical and health care, aviation, electronics, printing, and optical instruments. The advantages of UV curing adhesives are that the adhesives formulated on demand have very high transmittance, excellent reliability in high temperature and high humidity environments, and good water resistance. The UV curing adhesive is 100% cured to form a film, no solvent volatilization pollution problem, fast curing speed, energy saving, and high production efficiency. Acrylate UV curing adhesives are mixed with various modified acrylate resins (or prepolymers) and acrylate monomers, together with various additives such as adhesion promo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J167/06C09J163/00C09J175/14C09J11/06C09J4/02

Inventor 宋晓龙张一帆韩文明周莉

Owner JIANGSU HECHENG ADVANCED MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com