Flame-retardant bismaleimide resin

A technology of maleimide resin and bismaleimide, which is applied in the field of flame retardant polymer materials, can solve problems such as difficulty in meeting flame retardant requirements, and achieve the effect of excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

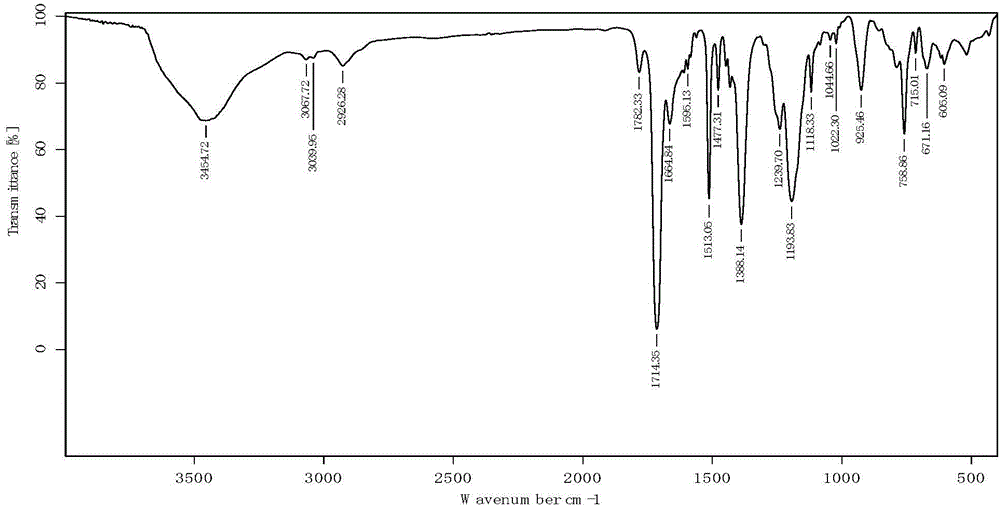

Embodiment 1

[0036] Embodiment 1: prepare the bismaleimide containing phosphaphenanthrene group

[0037] In this embodiment, the structural formula is The diphenylmethane bismaleimide is the bismaleimide of raw material preparation containing phosphaphenanthrene group, and the structural formula of the bismaleimide containing phosphaphenanthrene group of preparation is:

[0038]

[0039] The preparation method of the present embodiment comprises the following steps:

[0040] Step 1. Dissolve 10.0g DOPO in N,N-dimethylformamide to obtain 50mL DOPO solution;

[0041] Step 2: Add 16.6g of diphenylmethane bismaleimide and N,N-dimethylformamide into the reactor at a molar ratio of 1:10, stir evenly at 50°C under nitrogen protection, and then Add the DOPO solution described in step 1 dropwise to the reactor under constant temperature conditions, keep the temperature of the reaction system at 160° C. after the dropwise addition, and stir for 1 h; the drop rate of the DOPO solution is 1 mL / m...

Embodiment 2

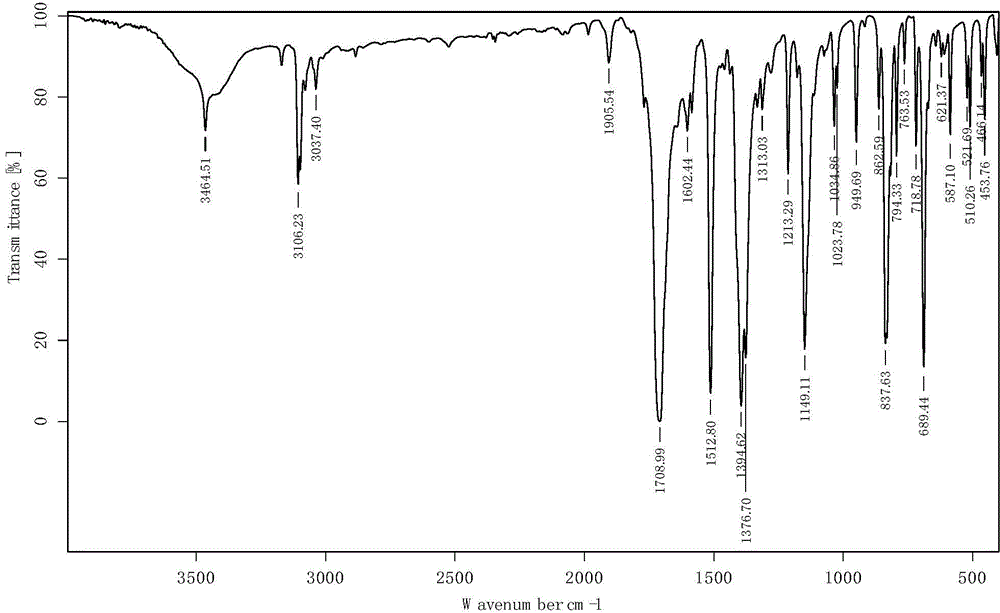

[0045] Embodiment 2: prepare the bismaleimide containing phosphaphenanthrene group

[0046] In this embodiment, the structural formula is The 2,2-diphenylpropane bismaleimide is the bismaleimide containing phosphaphenanthrene group prepared as a raw material, and the structural formula of the prepared bismaleimide containing phosphaphenanthrene group is:

[0047]

[0048] The preparation method of the present embodiment comprises the following steps:

[0049] Step 1. Dissolve 10.0g DOPO in dimethyl sulfoxide to obtain 50mL DOPO solution;

[0050] Step 2: Add 21.3g of 2,2-diphenylpropane bismaleimide and dimethyl sulfoxide into the reactor at a molar ratio of 1:50, stir evenly at 90°C under nitrogen protection, and then Add the DOPO solution described in step 1 dropwise to the reactor at a constant temperature, keep the temperature of the reaction system at 90°C after the dropwise addition, and stir for 5 hours; the drop rate of the DOPO solution is 3mL / min;

[0051] Ste...

Embodiment 3

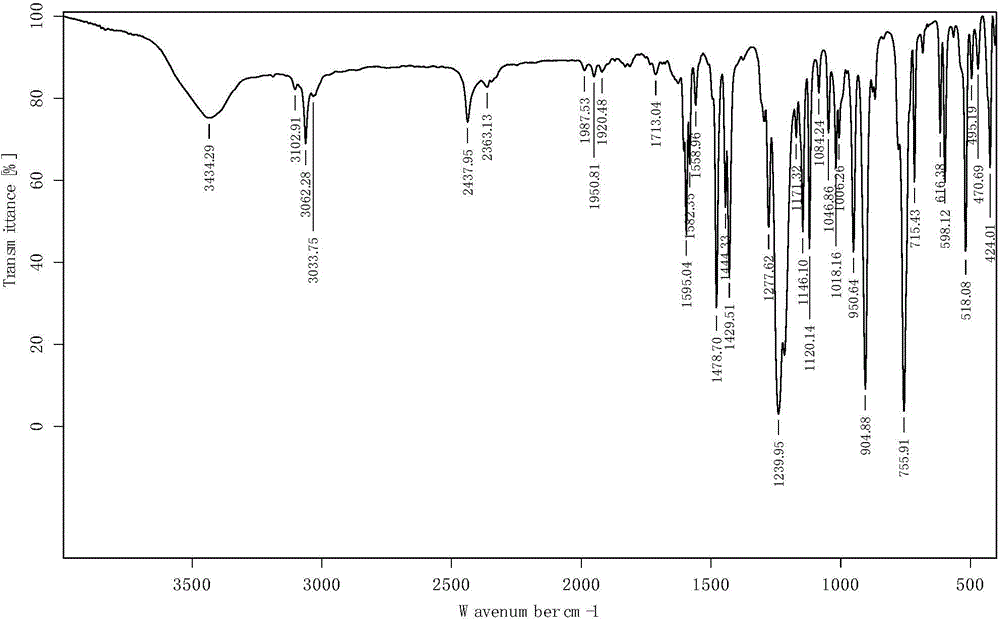

[0054] Embodiment 3: prepare the bismaleimide containing phosphaphenanthrene group

[0055] In this embodiment, the structural formula is The benzophenone bismaleimide is the bismaleimide of raw material preparation containing phosphaphenanthrene group, and the structural formula of the bismaleimide containing phosphaphenanthrene group of preparation is:

[0056]

[0057] The preparation method of the present embodiment comprises the following steps:

[0058] Step 1. Dissolve 10.0g DOPO in acetone to obtain 50mL DOPO solution;

[0059] Step 2. Add 25.67g of benzophenone bismaleimide and 1,3-dimethyl-2-imidazolidinone into the reactor at a molar ratio of 1:30), under nitrogen protection, at 120°C Stir evenly under the same conditions, then add the DOPO solution described in step 1 dropwise to the reactor under constant temperature conditions, keep the temperature of the reaction system at 140°C after the dropwise addition, and stir for 3 hours; the drop rate of the DOPO s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com