Halogen-free flame-retardant prepolymer, and prepreg and laminated board made from same

A prepreg and prepolymer technology, applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., can solve the problems of migration or exudation, low melting point, poor flame retardancy, etc., and achieve bending strength and shear The effect of strength improvement and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

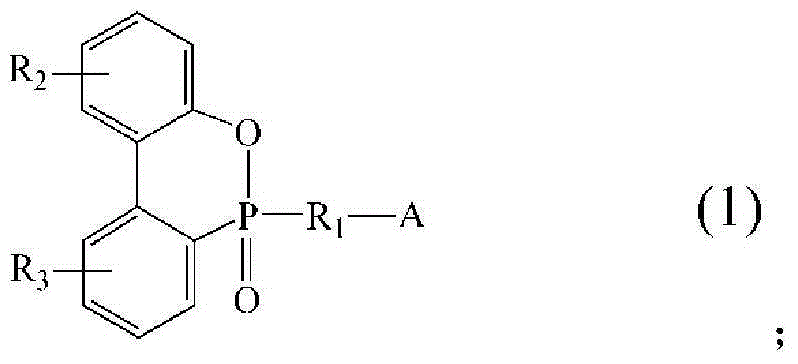

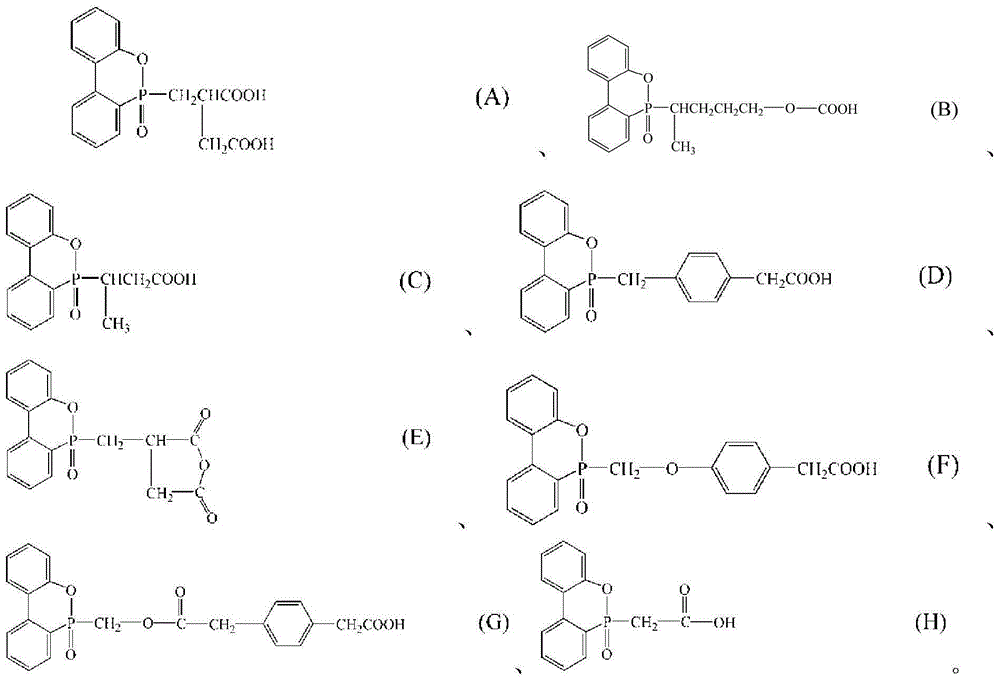

Method used

Image

Examples

Embodiment 1

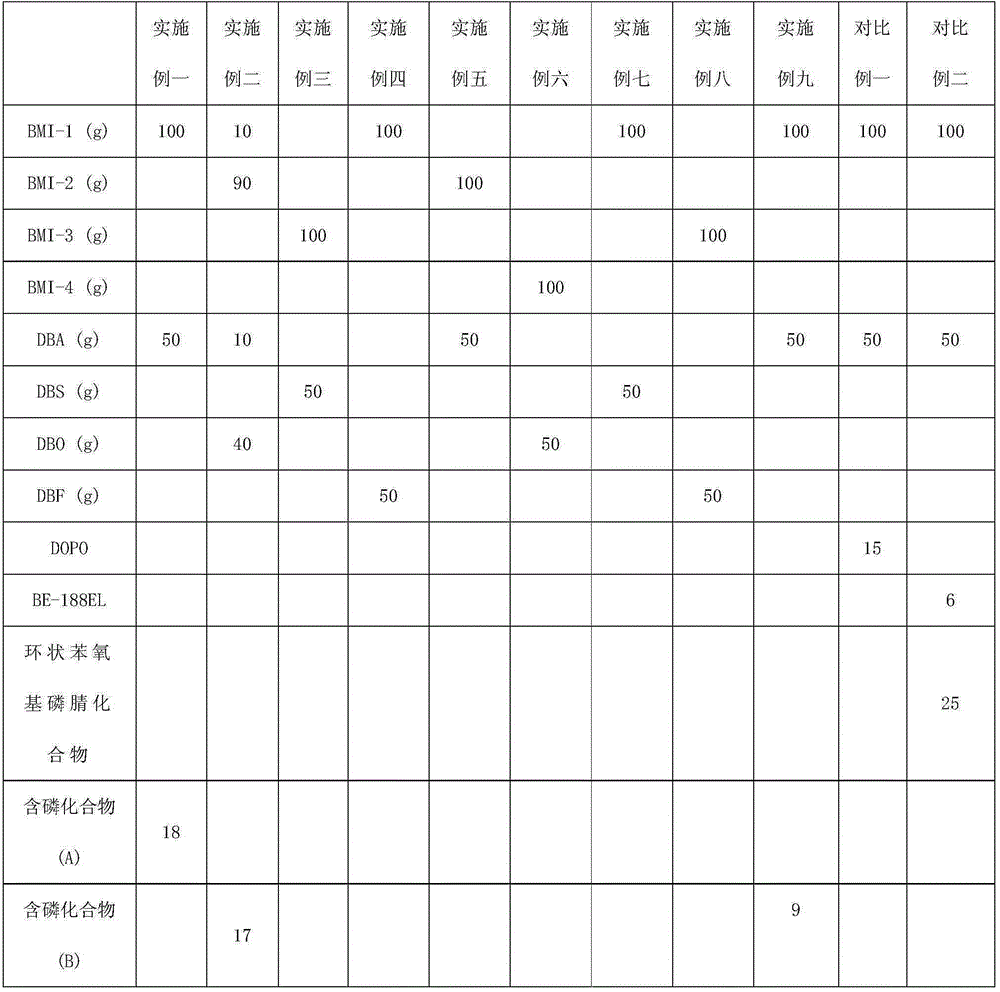

[0050] Take BMI-1100g, DBA50g, and 18g of phosphorus-containing compound (A) into a 500ml reaction bottle, use an oil bath to slowly heat to 150°C and keep stirring for 1h to obtain bismaleimide / allyl / containing Phosphorus compound ternary copolymerization prepolymer, after the reaction is completed, cool to room temperature.

Embodiment 2

[0052] Take BMI-120g, BMI-280g, DBO40g, DBA10g, phosphorus-containing compound (B) 17g into a 500ml reaction bottle, use an oil bath to slowly heat to 130°C and keep stirring for 4h to obtain bismaleimide / Allyl / phosphorous compound terpolymer prepolymer, after the reaction is completed, cool to room temperature.

Embodiment 3

[0054] Take 100g of BMI-3, 50g of DBS, and 15g of phosphorus-containing compound (C) into a 500ml reaction bottle, use an oil bath to slowly heat to 120°C and keep stirring for 5h to obtain bismaleimide / allyl / phosphorus-containing Compound ternary copolymerization prepolymer, after the reaction is completed, cool to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com