Resin composition and molded article comprising the same

A technology of resin composition and compound, which is applied in the field of resin composition and its formed body, can solve the problems of resin composition strength reduction, plasticizer exudation, plasticizer volatilization, etc., and achieve excellent mechanical properties, The effect of excellent melt fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

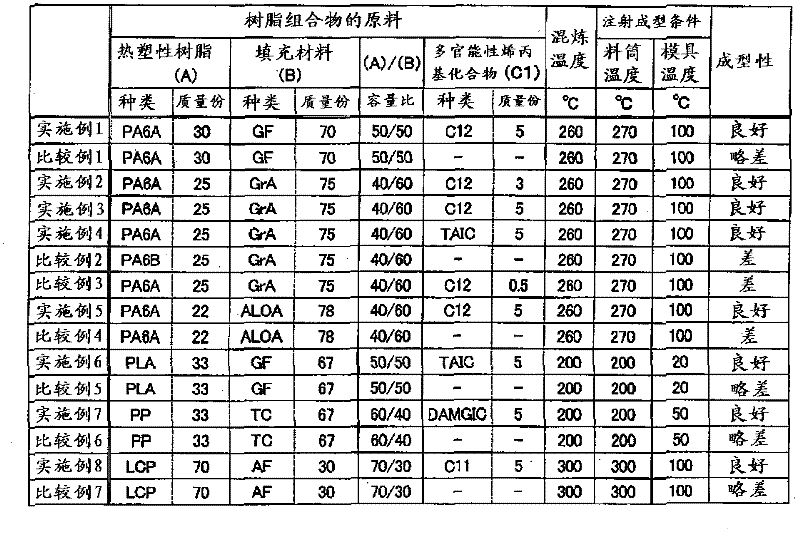

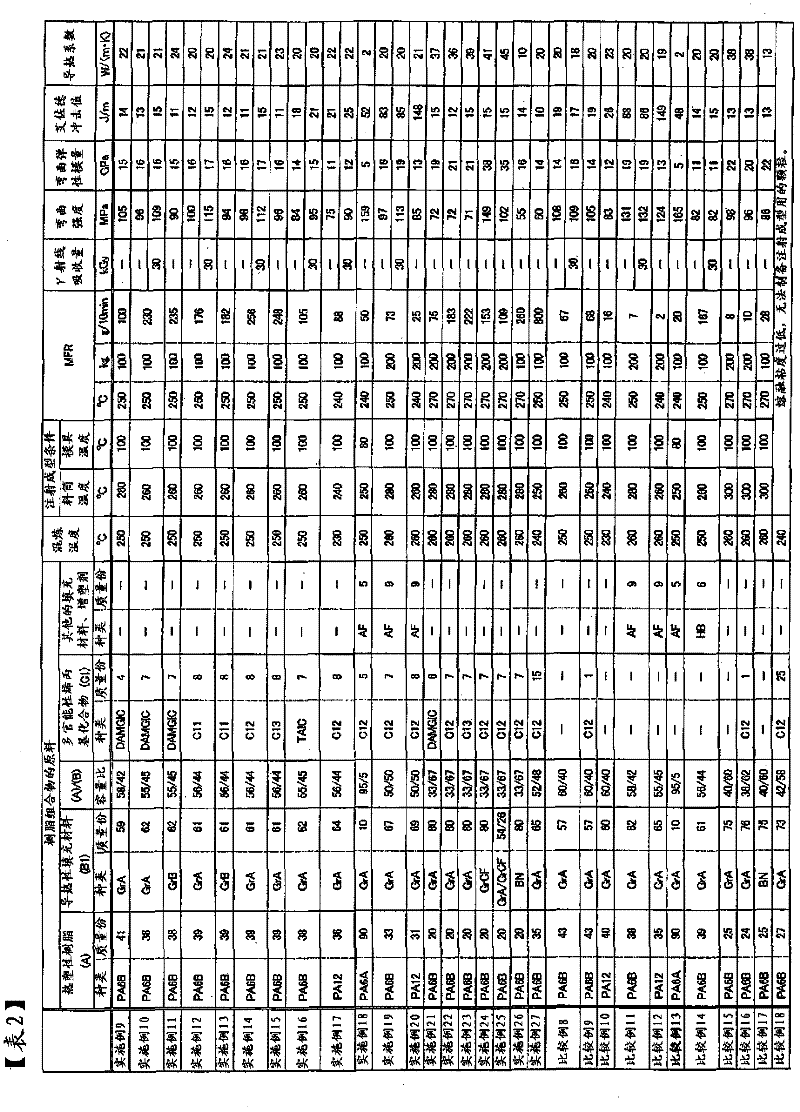

[0081] Hereinafter, the present invention will be specifically described based on examples. However, the present invention is not limited to these Examples.

[0082] In the following examples and comparative examples, the test methods for various physical property values are as follows.

[0083] [1] MFR (melt index):

[0084] The pellets of the thermoplastic resin composition were measured for their MFR value at a predetermined load and a predetermined temperature using a falling flow meter (manufactured by Toyo Seiki Seisakusho). In this case, a fine hole die having a diameter of 1 mm x a length of 10 mm was used.

[0085] [2] Bending strength, bending modulus of elasticity:

[0086] Measurement was performed based on the method described in ASTM standard D-790.

[0087] [3] Impact strength:

[0088] Izod impact strength was measured using a notched test piece according to the method described in ASTM standard D-256.

[0089] [4] Thermal conductivity:

[0090] The ca...

manufacture example 1

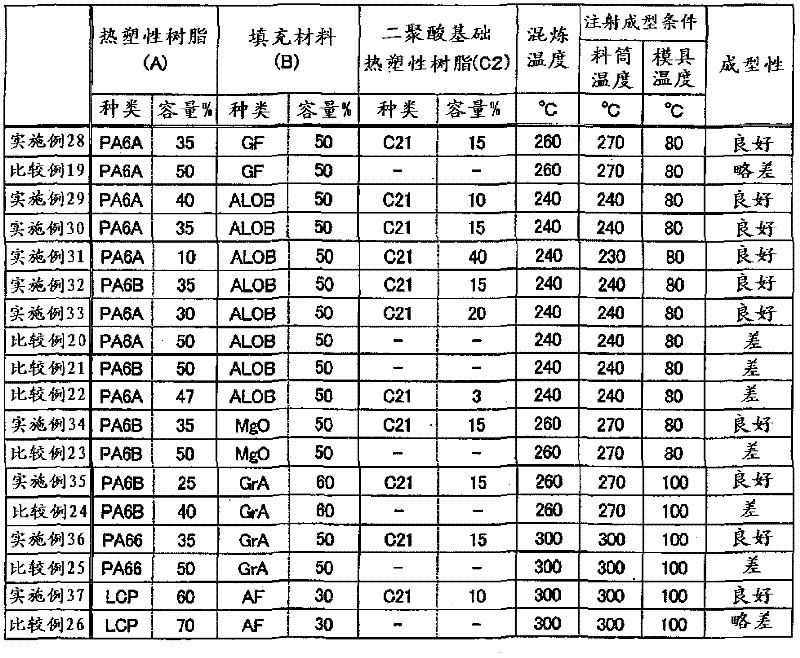

[0137] ·Manufacturing example 1 (C21)

[0138] Dimer acid (manufactured by Tsukino Food Industry Co., Ltd., hydrogen-free) / 1,3-bis(aminomethyl)benzene=46.5 / 53.5 (molar ratio) ratio of raw materials was charged into the reaction tank, at 240°C , and let it react for 2 hours. After the reaction, it was taken out and cut to obtain dimer acid base polyamide resin particles. The resulting pellets had a melt index (MFR) of 1800 g / min at 230° C. and 21.18 N.

manufacture example 2

[0139] ·Manufacturing example 2 (C22)

[0140] Dimer acid (produced by Tsukino Food Industry Co., Ltd., without hydrogen addition) / 65.3% hexamethylenediamine aqueous solution / caprolactam = 10.3 / 7.3 / 82.4 (molar ratio) Raw materials were charged into the reaction tank, and the reaction tank was heated at 250° C. , and let it react for 2 hours. After the reaction, it was taken out and cut to obtain dimer acid base polyamide resin particles. The resulting pellets had a melt index (MFR) of 1300 g / min at 230° C. and 21.18 N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com