Modified bismaleimide resin prepolymer and preparation method thereof

A technology of bismaleimide resin and bismaleimide, which is applied in the field of modified bismaleimide resin prepolymer for prepreg and its preparation, can solve the problem of small elongation at break, Poor performance and toughness, high cross-linking density, etc., to achieve moderate melt viscosity, improve mechanical properties, and improve process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of modified bismaleimide resin prepolymer, its preparation method comprises the steps:

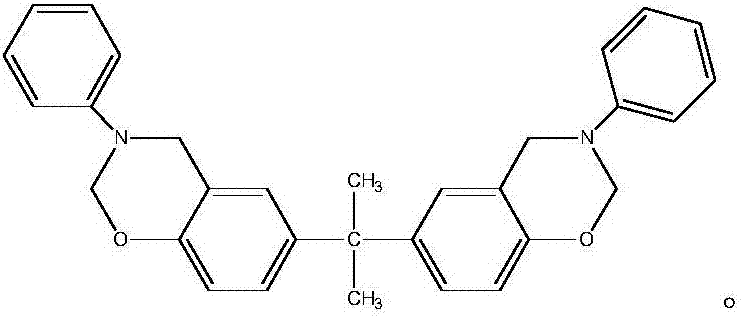

[0030] Weigh 43g of diallyl bisphenol A and put it in a three-necked flask, heat up to 130°C under oil bath and stirring conditions, then add 100g of diphenylmethane bismaleimide to react for 35min, cool down to 120°C Add 25g m-aminophenylacetylene, after the bismaleimide dissolves to obtain a uniform transparent mixed solution, time the reaction for 30 minutes, then add 32g bisphenol A-aniline benzoxazine and 6g 2-ethyl-4-methyl After the imidazole was stirred for 15 minutes to mix evenly, the reaction was stopped, and the reaction was quickly removed to obtain a dark reddish-brown uniform and transparent modified bismaleimide resin prepolymer.

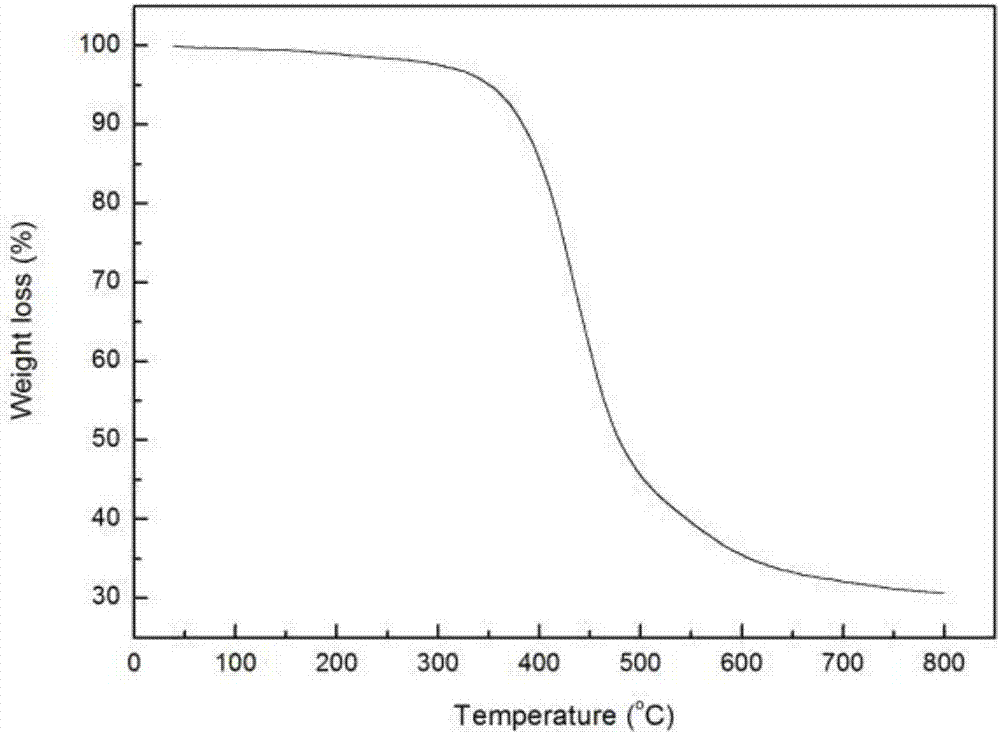

[0031] The modified bismaleimide resin prepolymer obtained in this example was defoamed in a vacuum oven at 115°C for 45 minutes, and then placed in a blast oven for heating and curing to obtain a cured product of the modified bisma...

Embodiment 2

[0035] A kind of modified bismaleimide resin prepolymer, its preparation method comprises the steps:

[0036] Weigh 65g of diallyl bisphenol A and 16g of p-aminophenylacetylene into a three-necked flask, heat up to 120°C under oil bath and stirring conditions, then add 100g of diphenylmethane bismaleimide, wait After dissolving the bismaleimide to obtain a homogeneous transparent mixture, time the reaction for 40 minutes, then add 64g of bisphenol A-aniline benzoxazine and 7g of 2-ethyl-4-methylimidazole, stir for 15 minutes and stop React and remove quickly to obtain dark reddish-brown uniform and transparent modified bismaleimide resin prepolymer.

[0037] The modified bismaleimide resin prepolymer obtained in this example was defoamed in a vacuum oven at 115°C for 45 minutes, and then placed in a blast oven for heating and curing to obtain a cured product of the modified bismaleimide resin. The curing system is carried out in sequence as follows: heating at 140°C for 2h, h...

Embodiment 3

[0041] A kind of modified bismaleimide resin prepolymer, its preparation method comprises the steps:

[0042]Weigh 22g of diallyl bisphenol A and 29g of o-diallyl bisphenol A diglycidyl ether into a three-necked flask, heat up to 130°C under oil bath and stirring conditions, and then add 100g of diphenylmethane Bismaleimide, react for 40 minutes, cool down to 120°C, add 16g of m-aminophenylacetylene to dissolve the bismaleimide to obtain a homogeneous transparent mixture, then react for 15 minutes by time, then add 90g of bisphenol A-aniline benzo Oxazine and 8 g of 2-methylimidazole were stirred for 15 minutes to stop the reaction and then removed quickly to obtain a dark reddish-brown uniform and transparent modified bismaleimide resin prepolymer.

[0043] The modified bismaleimide resin prepolymer obtained in this example was defoamed in a vacuum oven at 115°C for 45 minutes, and then placed in a blast oven for heating and curing to obtain a cured product of the modified bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com