High toughness and high and low temperature resistant bismaleimide resin prepolymer and preparation method thereof

The technology of bismaleimide resin and bismaleimide is applied in the field of high toughness, high and low temperature resistant bismaleimide resin prepolymer and its preparation, and can solve the peak temperature of resin thermal decomposition of 800°C The thermal performance parameters such as carbon residue rate are low, and the toughness is decreased, so as to achieve the effect of improving the mechanical strength, improving the toughness and improving the toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A high toughness high and low temperature resistant bismaleimide resin prepolymer, the specific preparation method is as follows:

[0036]Prepare a 500ml three-necked flask with a thermometer and mechanical stirring, first add 45g of diallyl bisphenol A and 60g of diallyl bisphenol A diglycidyl ether (epoxy value 0.39), heat to 130°C, then add 100g Diphenylmethane bismaleimide was reacted for 40 minutes, then the temperature of the reaction system was lowered to 110°C, 40 g of methyl hexahydrophthalic anhydride was added, and the reaction was carried out at constant temperature until a uniform and transparent mixture was obtained. - Stir 4-methylimidazole for 10 minutes to disperse the accelerator uniformly in the system, stop heating to obtain a high toughness high and low temperature resistant bismaleimide resin prepolymer. The resin prepolymer is a brown-red viscous liquid at room temperature.

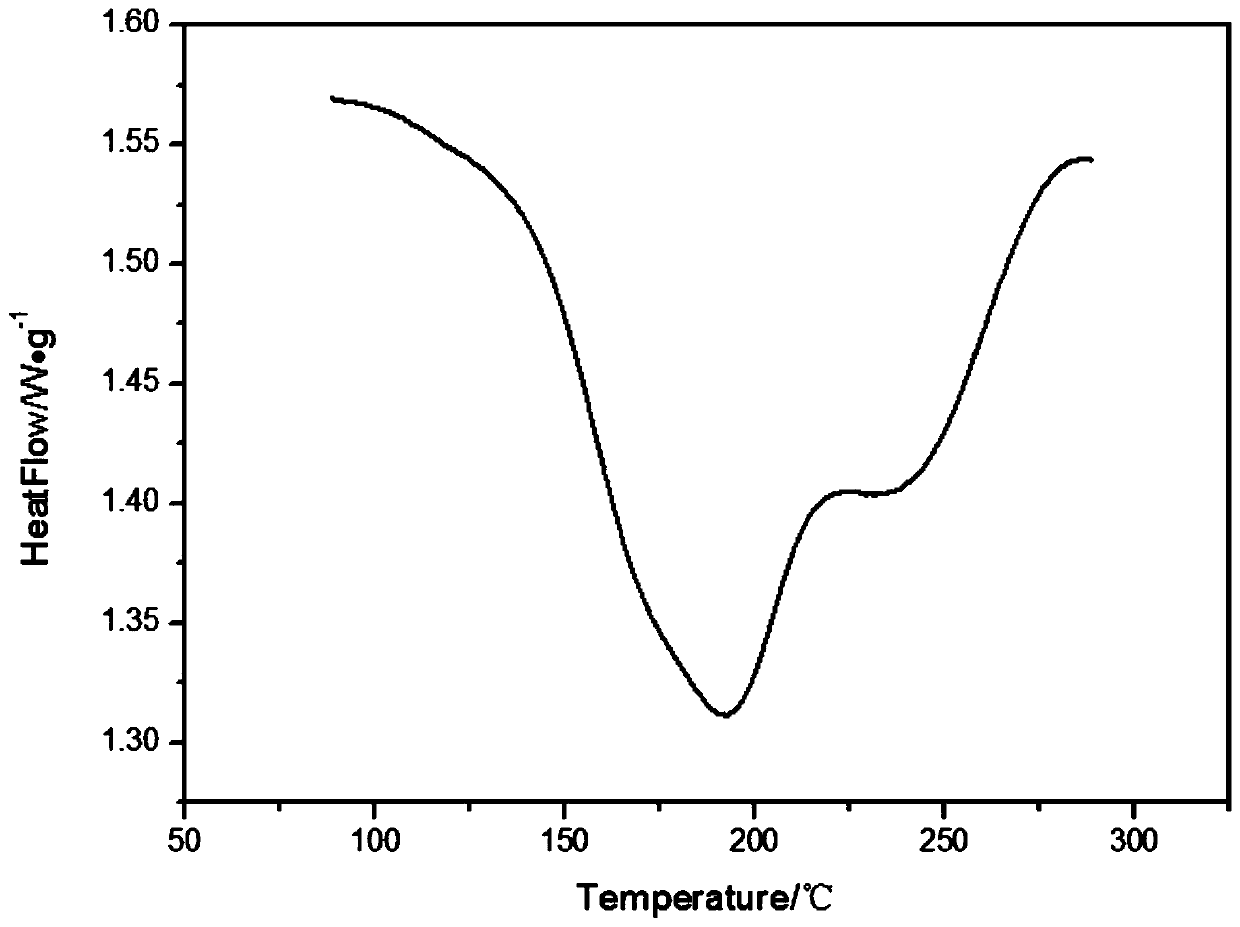

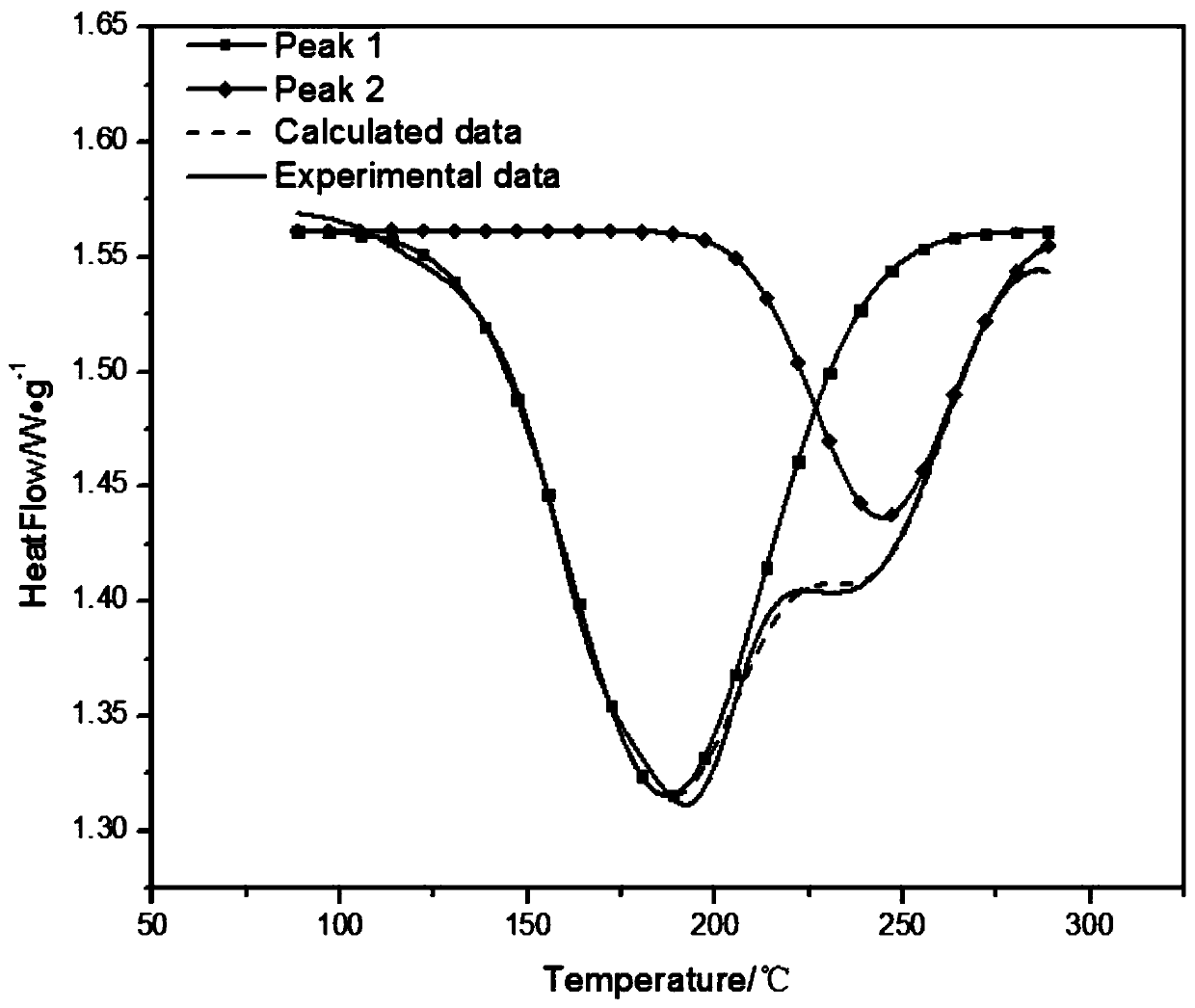

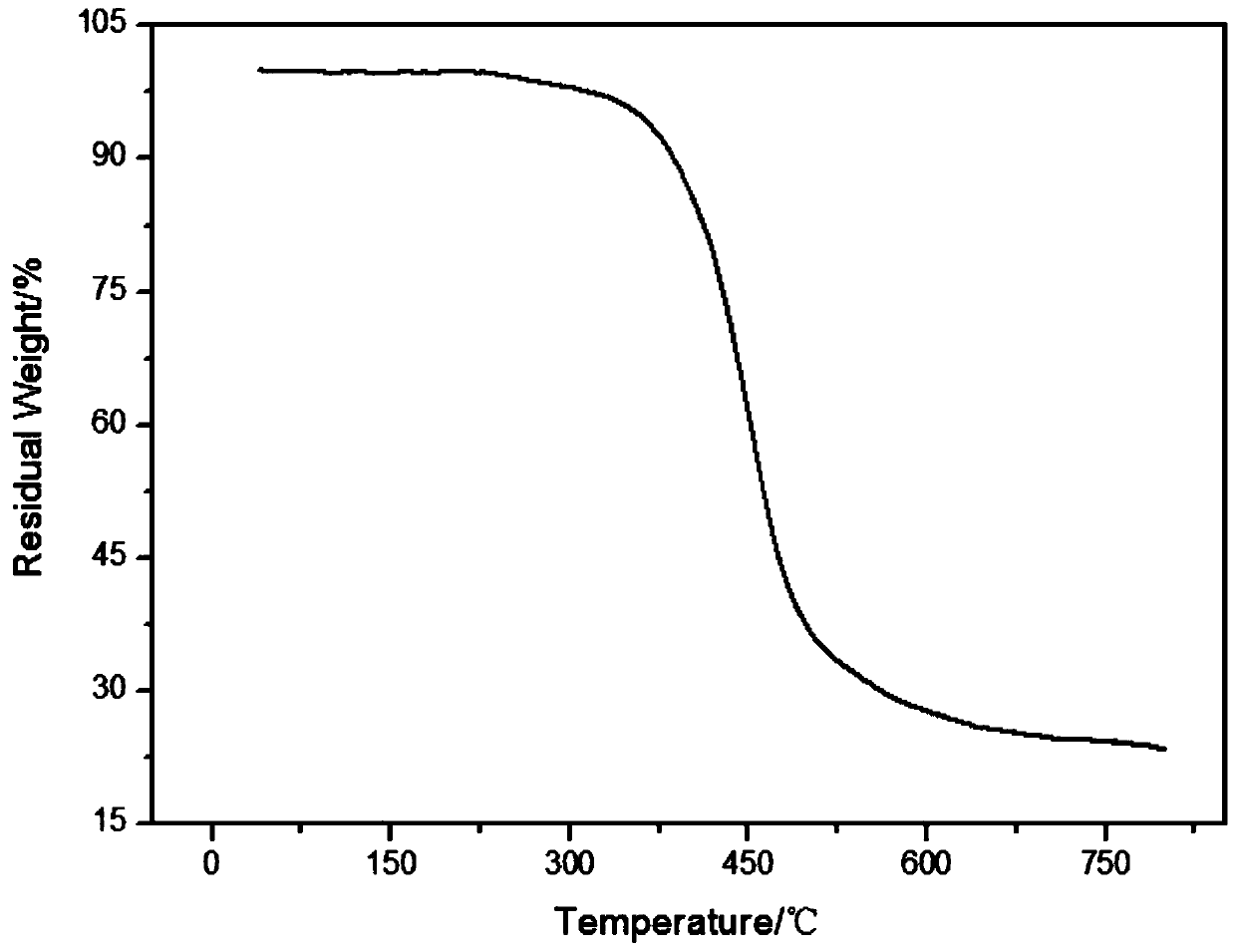

[0037] The resin prepolymer obtained in this example has good solubilit...

Embodiment 2

[0044] A high toughness high and low temperature resistant bismaleimide resin prepolymer, the specific preparation method is as follows:

[0045] Prepare a 500ml three-necked flask with a thermometer and mechanical stirring, first add 65g of diallyl bisphenol A and 30g of diallyl bisphenol A diglycidyl ether, heat to 140°C, then add 100g of diphenylmethane bismaleyl Imine, stirred and reacted at constant temperature for 10 minutes, then cooled the reaction system to 120°C, added 15g of methyl hexahydrophthalic anhydride, reacted at constant temperature until the resin system was completely dissolved and uniform, then kept the temperature for 10 minutes, and then added 3g of 2-ethyl-4-methyl The imidazole was stirred for 5 minutes to disperse the accelerator uniformly in the system, and the heating was stopped to obtain a modified bismaleimide resin prepolymer. The resin prepolymer is a brown-red viscous liquid at room temperature.

[0046] The modified bismaleimide resin prep...

Embodiment 3

[0052] A high toughness high and low temperature resistant bismaleimide resin prepolymer, the specific preparation method is as follows:

[0053] Prepare a 500ml three-necked flask with a thermometer and mechanical stirring, first add 45g of diallyl bisphenol A and 60g of diallyl bisphenol A diglycidyl ether, heat to 130°C and then add 100g of diphenylmethane bismaleimide Amine, stirred and reacted at constant temperature for 60 minutes, then cooled the reaction system to 100°C, added 30g of methyl hexahydrophthalic anhydride, reacted at constant temperature until the system was completely dissolved and uniform, then kept the temperature for 10 minutes, added 3g of 2-ethyl-4-methylimidazole and stirred After 5 minutes, the accelerator is uniformly dispersed in the system, and the heating is stopped to obtain a modified bismaleimide resin prepolymer. The resin prepolymer is a brown-red viscous liquid at room temperature.

[0054] The modified bismaleimide resin prepolymer obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com