High-peel-strength hot melt adhesive composition

A technology of hot-melt adhesives and compositions, which is applied in the field of hot-melt adhesive compositions for bonding polyester films, can solve the problems of easy detachment of polyester films and low T-peel strength, and achieve easy pre-coating, high Moderate peel strength and melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 50 parts by weight of PES-130T and 50 parts by weight of TYA were mixed, heated to about 200°C, melted and blended uniformly to obtain the copolyester hot melt adhesive composition A of the present invention.

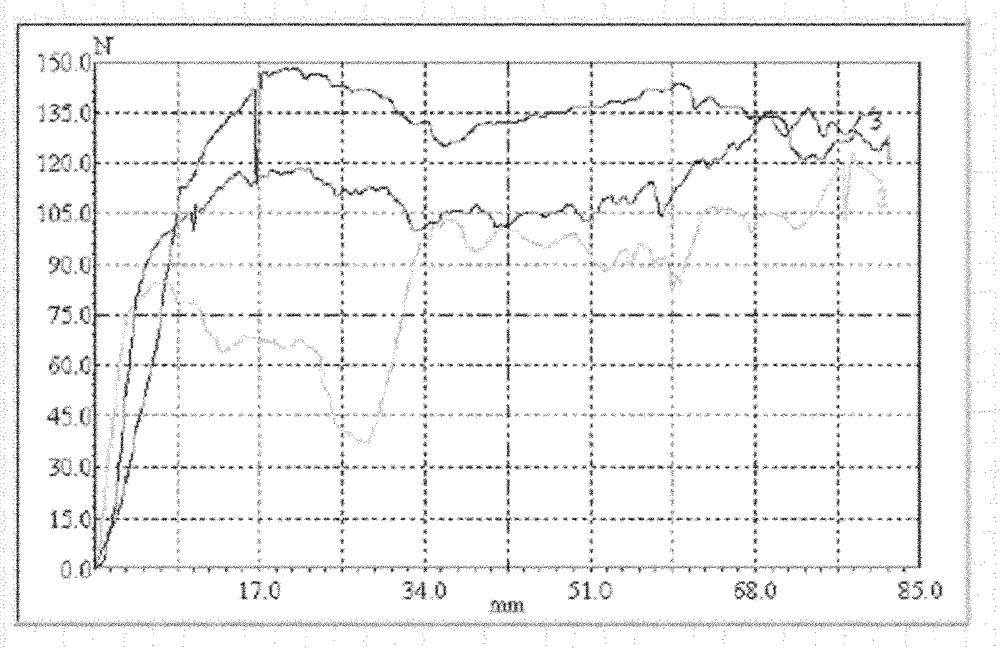

[0036] The copolyester hot-melt adhesive composition of the present invention is evenly coated on the PET polyester film, and then bonded with another layer of PET polyester film by hot pressing. The hot pressing temperature is about 200 ° C, and the thickness of the adhesive layer is ≥10μ, the thickness of PET polyester film is 0.1mm, and the hot pressing time of manual electric iron is 5 seconds. Cut into 2.5cm wide test strips after bonding and carry out T-type peel strength test, the tensile speed is 50mm / min, and the measured T-type peel strength ≥ 40N / cm (see attached figure 1 ). However, after 2 months of storage, the T-peel strength decreased somewhat. In addition, the softening point measured by the above-mentioned standard method was 120°C, the melt v...

Embodiment 2

[0038] Accurately weigh each raw material according to the following formula, heat to about 200°C, and melt and blend uniformly to prepare the copolyester hot-melt adhesive composition B of the present invention, wherein an appropriate amount of carboxylic acid grafted polypropylene wax is added.

[0039] Component name Parts by weight

[0040] PES-130T copolyester hot melt adhesive 50

[0041] TYA copolyester hot melt adhesive 50

[0042] Licomont AR504 5

[0043] 105

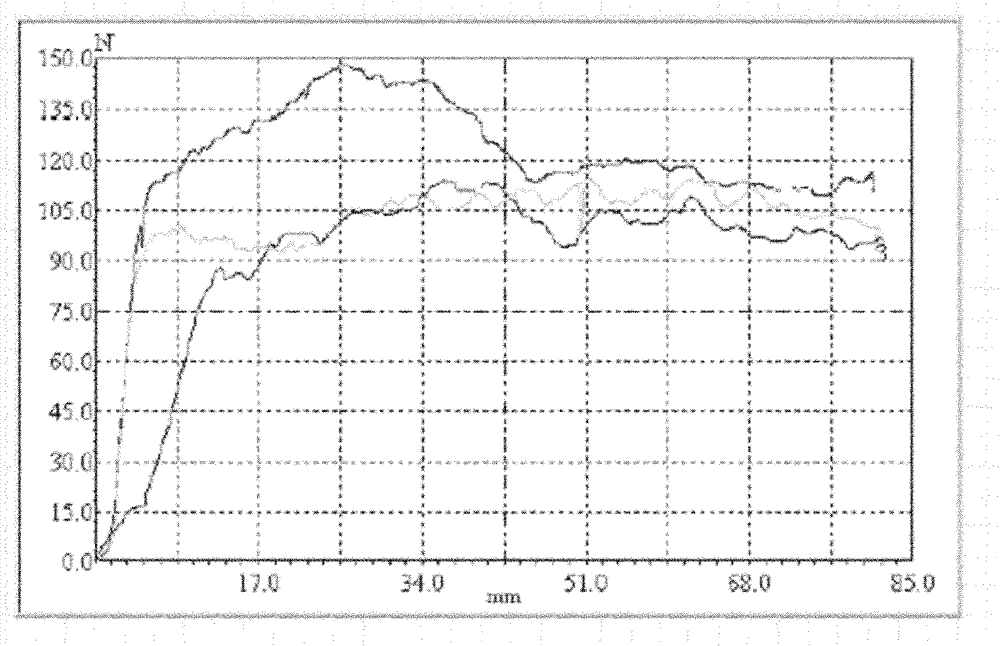

[0044]The copolyester hot-melt adhesive composition B of the present invention that is prepared is uniformly coated on the PET polyester film by the same method as Example 1, and carries out T-type peel strength test, and the T-type peel strength measured on the same day after bonding Strength ≥ 50N / cm (see attached figure 2 ). At the same time, the blended hot melt adhesive was measured, and its softening point was 120° C., its melt viscosity was 52800 mPa.s / 200° C., and its hardness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com