Preparation method of liquid-crystal allyl-compound-modified bismaleimide resin

A technology of bismaleimide resin and allyl compound, applied in the field of preparation of bismaleimide resin, to achieve the effect of increasing flexural strength and flexural modulus, and increasing heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

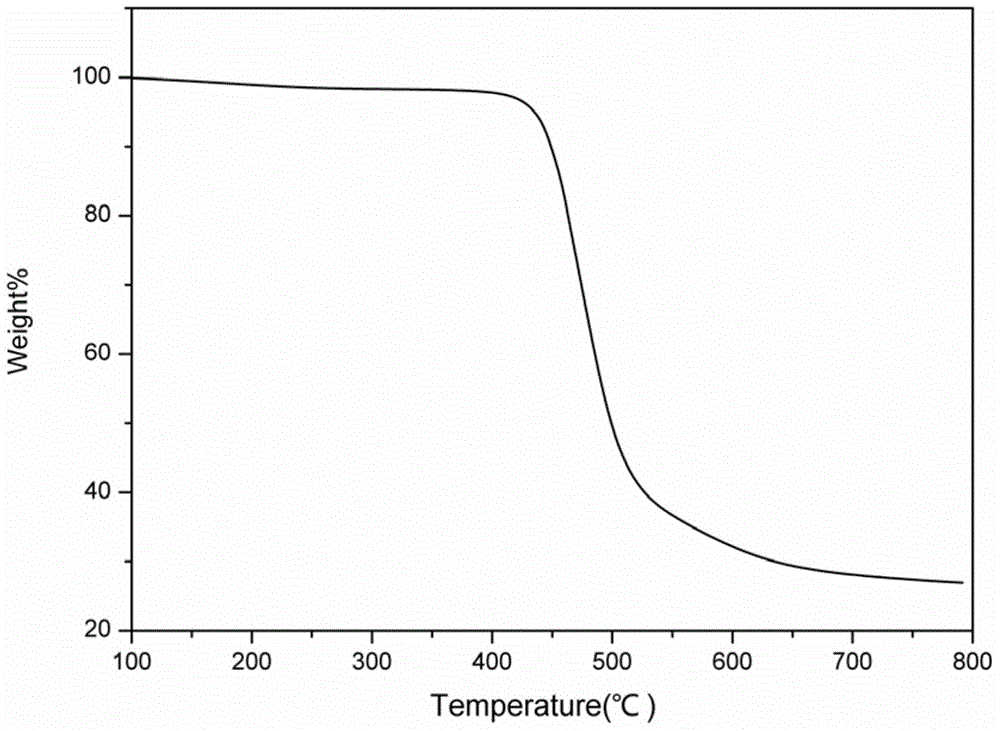

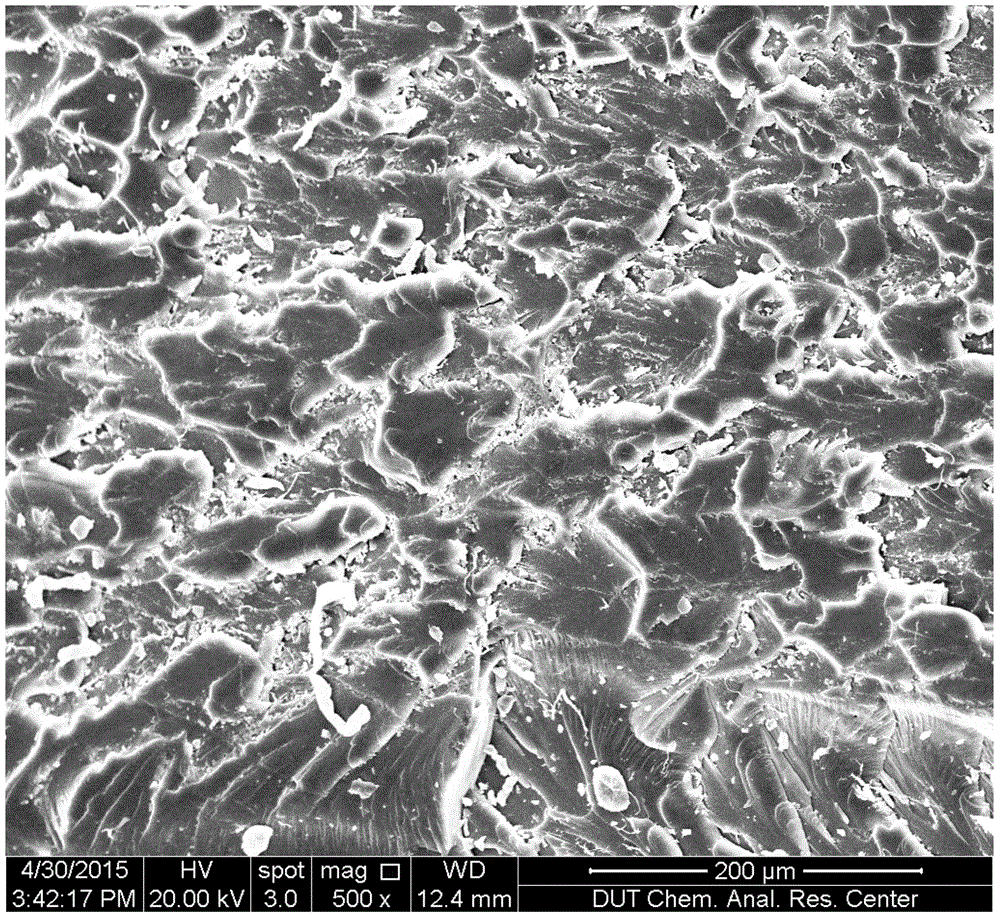

[0017] Heat and melt 2.06g of 1,4'-di(4-allyloxybenzoic acid)phenyl ester at 165°C, add 13.26g of 2,2'-diallyl bisphenol A to melt, then add 19.68g of N ,N'-4.4'-diphenylmethane bismaleimide monomer is melt-copolymerized at 140°C until the system becomes a homogeneous reddish-brown transparent liquid, and then reacted with heat preservation to obtain a modified bismaleimide resin. Put the obtained resin in a vacuum oven at 140°C for defoaming treatment for 50 minutes, and then pour it into a mold preheated to 140°C and coated with a release agent for curing. The curing process is 180°C / 1h+210 ℃ / 2h+250℃ / 6h. After curing, the bismaleimide cured resin modified by the liquid crystal allyl compound is obtained.

[0018] control group

[0019] The components are N,N'-1.4'-diphenylmethane bismaleimide and 2,2'-diallyl bisphenol A;

[0020] After heating and melting 14.98g of 2,2'-diallyl bisphenol A at 70°C, add 20.01g of N,N'-4.4'-diphenylmethane bismaleimide monomer at 140°C for...

Embodiment 2

[0022] Heat and melt 4.05g of 1,4'-di(4-allyloxybenzoic acid)phenyl ester at 165°C, add 11.59g of 2,2'-diallyl bisphenol A to melt, then add 19.36g of N ,N'-4.4'-diphenylmethane bismaleimide monomer is melt-copolymerized at 140°C until the system becomes a homogeneous reddish-brown transparent liquid, and then reacted with heat preservation to obtain a modified bismaleimide resin. Put the obtained prepolymer into a vacuum drying oven at 140°C for defoaming treatment for 50 minutes, and then pour it into a mold preheated to 140°C and coated with a release agent for curing. The curing process is 180°C / 1h +210°C / 2h+250°C / 6h. After curing, the bismaleimide cured resin modified by the liquid crystal allyl compound is obtained.

Embodiment 3

[0024] Heat and melt 5.97g of 1,4'-di(4-allyloxybenzoic acid)phenyl ester at 165°C, add 9.98g of 2,2'-diallyl bisphenol A to melt, then add 19.05g of N ,N'-4.4'-diphenylmethane bismaleimide monomer is melt-copolymerized at 150°C until the system becomes a homogeneous reddish-brown transparent liquid, and then the modified bismaleimide resin is obtained by heat preservation reaction. Put the obtained prepolymer into a vacuum drying oven at 150°C for defoaming treatment for 50 minutes, and then pour it into a mold preheated to 150°C and coated with a release agent for curing. The curing process is 180°C / 1h +210°C / 2h+250°C / 6h. After curing, the bismaleimide cured resin modified by the liquid crystal allyl compound is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com