Fluorine-containing low-dielectric-loss bismaleimide resin, and preparation method and application thereof

A technology of bismaleimide resin and bismaleimide, applied in the field of thermosetting resin and its preparation, can solve the problem that bismaleimide resin cannot meet the application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

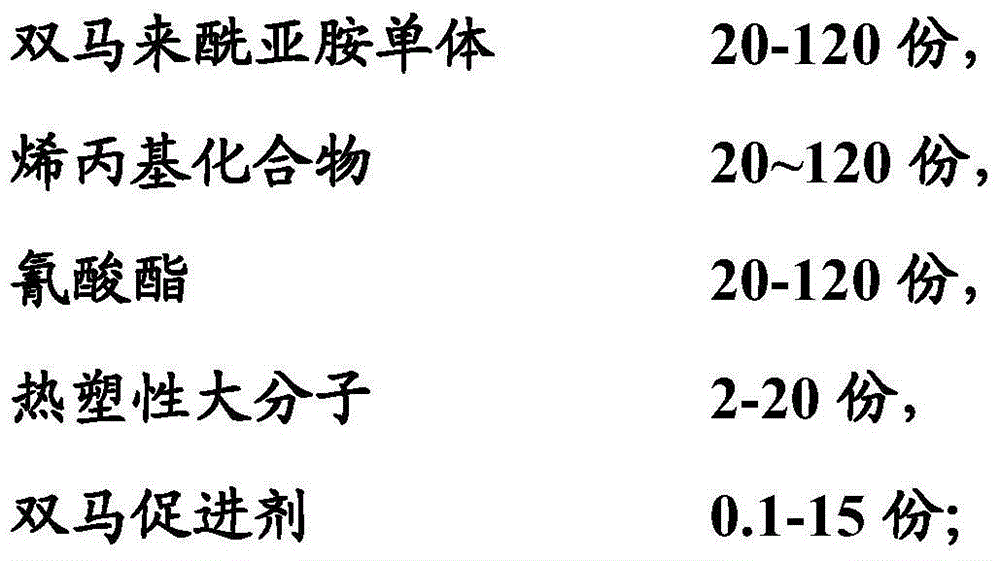

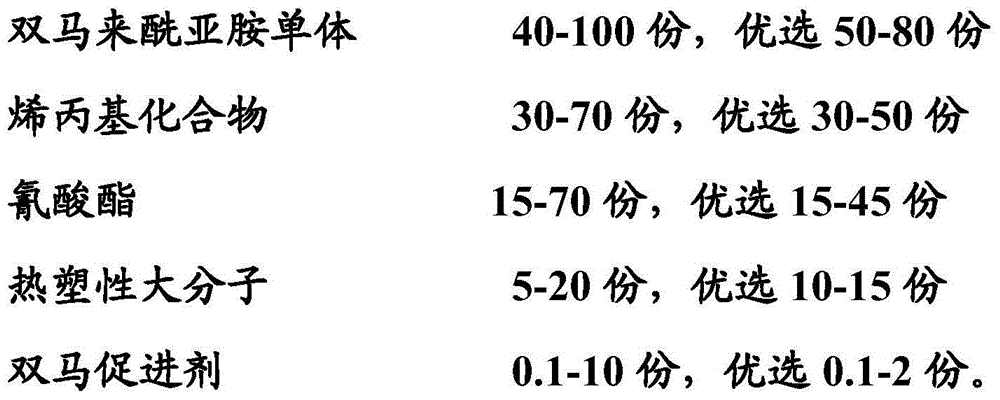

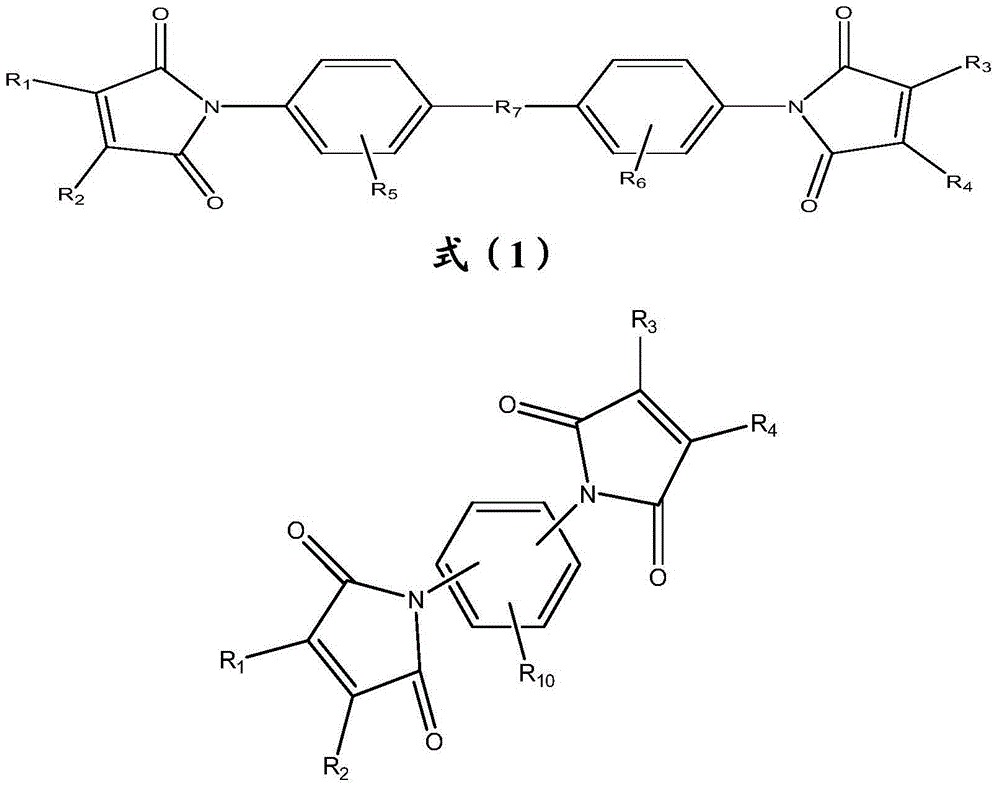

Method used

Image

Examples

Embodiment 1

[0071] Add 30g of diallyl bisphenol A to a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, slowly raise the temperature to 130°C, add 10g of PEI after the temperature stabilizes, and add 60g of 2,2'-bisphenol A after the PEI is dissolved [4-(4-Maleimidophenoxy)phenyl]hexafluoropropane and 20g bisphenol A cyanate, react at a constant temperature of 130°C until the resin system is uniform and transparent, keep the reaction for 30min, and cool down to 80°C 1.5 g of azobisisobutyronitrile was added at ℃, and after stirring for 10 minutes, a modified fluorine-containing bismaleimide resin was obtained, which was an orange-yellow viscous liquid.

Embodiment 2

[0073] Add 42g of hexafluorodiallyl bisphenol A to a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, slowly raise the temperature to 130°C, add 15g of PEI after the temperature stabilizes, and add 68g of 2,2' after the PEI is dissolved -Bis[4-(4-maleimidophenoxy)phenyl]hexafluoropropane and 20g of bisphenol A cyanate, react at a constant temperature of 130°C until the resin system is uniform and transparent, keep the reaction for 30min, and cool down Add 1.5 g of benzoyl peroxide to 100° C. and stir for 10 minutes to obtain a modified fluorine-containing bismaleimide resin, which is an orange-yellow viscous liquid.

Embodiment 3

[0075] Add 42g of hexafluorodiallyl bisphenol A into a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, slowly raise the temperature to 130°C, add 15g of PPO after the temperature stabilizes, and add 68g of 2,2' after the PPO is dissolved -Bis[4-(4-maleimidophenoxy)phenyl]hexafluoropropane and 42g cyclopentadiene cyanate, react at a constant temperature of 130°C until the resin system is uniform and transparent, then keep the reaction for 30min, Cool down to 100° C., add 1.5 g of benzoyl peroxide, and stir for 10 minutes to obtain a modified fluorine-containing bismaleimide resin, which is an orange-yellow viscous liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com