Preparation of polyimide thermosetting resin and application thereof in two-layer method flexibility coat copper plate

A technology of polyimide resin and maleimide, which is applied in coatings, circuit substrate materials, and devices for coating liquid on the surface, etc., which can solve the problem of limited application, poor impact resistance and stress crack resistance issues such as reduced equipment and environmental conditions, low production costs, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

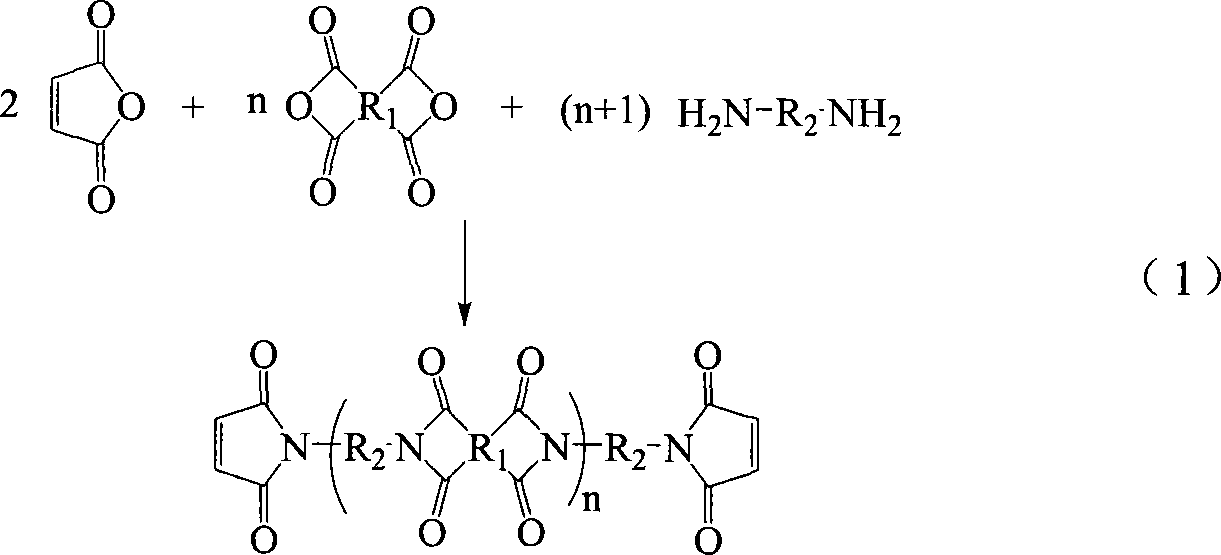

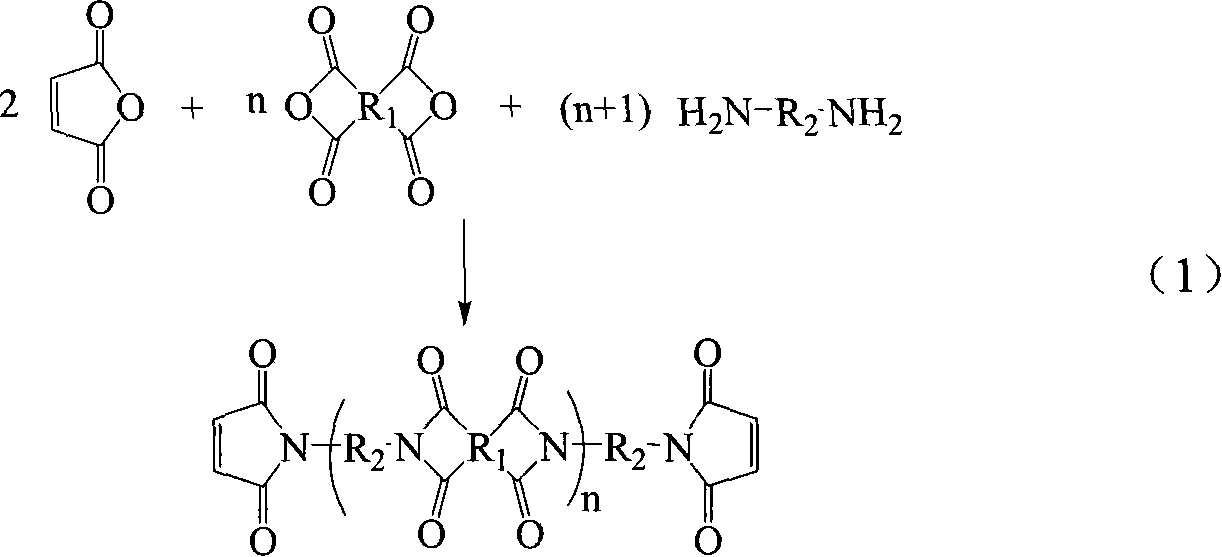

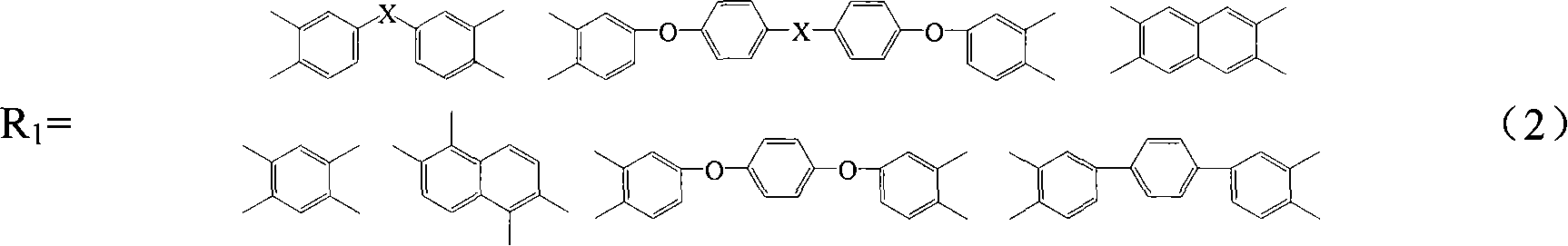

Method used

Image

Examples

Embodiment 1

[0033] 24.03 grams (0.12 moles) of 3,4'-diaminodiphenyl ether, 3.92 grams (0.04 moles) of maleic anhydride and 29.42 grams (0.10 mol) was successively added to NMP (229 milliliters), under nitrogen protection, after stirring at room temperature for 10 hours, 0.24 moles of dehydrating agent acetic anhydride (22.65 milliliters), 0.24 moles of dehydration catalyst triethylamine (33.47 milliliters) and NMP 153 milliliters, reacted at 50°C for 7 hours, and poured it into a large amount of absolute ethanol stirred at high speed to obtain a precipitate. The obtained precipitate was thoroughly washed successively with absolute ethanol and absolute ether, and vacuum-dried to obtain 47.16 g of maleimide-terminated polyimide resin.

[0034] Weigh 30 grams of the above-mentioned maleimide-terminated polyimide resin and 3 grams of diallyl bisphenol A, mix them, dissolve them in NMP (158 ml), and fully stir to form a homogeneous solution. Coat this solution on a copper foil with a thicknes...

Embodiment 2

[0036] With 4,4'-diaminodiphenyl ether 50.06 grams (0.25 mole), maleic anhydride 9.81 grams (0.10 mole) and 3,3',4,4'-diphenyl ether tetraacid dianhydride 62.13 grams ( 0.20 mole) was successively added in DMAc (488 milliliters), under the protection of nitrogen, after stirring at room temperature for 12 hours, add 0.75 moles (70.77 milliliters) of dehydrating agent acetic anhydride, 0.50 moles (69.73 milliliters) of dehydration catalyst triethylamine and DMAc 325 milliliters were reacted at 70° C. for 4 hours, and poured into a large amount of high-speed stirring absolute ethanol to obtain a precipitate. The obtained precipitate was washed thoroughly with anhydrous ethanol and anhydrous ether successively, and vacuum-dried to obtain 99.26 g of maleimide-terminated polyimide resin.

[0037] Weigh 80 grams of the above-mentioned maleimide-terminated polyimide resin and 13 grams of diallyl bisphenol A, mix them, dissolve them in DMAc (425 milliliters), and fully stir to form a h...

Embodiment 3

[0039] 4,4'-diaminodiphenylsulfone (4,4'-DDS) 86.90 grams (0.35 moles), maleic anhydride 9.81 grams (0.10 moles) and 2,2'-bis(3,4-di Carboxyphenyl) 133.27 grams (0.30 moles) of hexafluoropropane tetra-acid dianhydride were successively added to DMF (920 milliliters), under nitrogen protection, after stirring at room temperature for 16 hours, 1.40 moles (132.10 milliliters) of dehydrating agent acetic anhydride were added , 0.14 mol (19.52 milliliters) of dehydration catalyst triethylamine and 613 milliliters of DMF were reacted at 60° C. for 6 hours, and poured into a large amount of dehydrated ethanol stirred at high speed to obtain a precipitate. The obtained precipitate was thoroughly washed successively with absolute ethanol and absolute ether, and then vacuum-dried to obtain 200.00 g of maleimide-terminated polyimide resin.

[0040] Weigh 100 grams of the above-mentioned maleimide-terminated polyimide resin and 6 grams of diallyl bisphenol A, mix them, dissolve them in DM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com