Graphene conductive slurry as well as preparation method and application method of graphene conductive slurry

A technology of conductive paste and application method, applied in conductive coatings, conductive materials dispersed in non-conductive inorganic materials, epoxy resin coatings, etc., can solve problems such as graphene conductive paste research, and achieve a feasible and stable process. Good sex, prevent the effect of overlapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

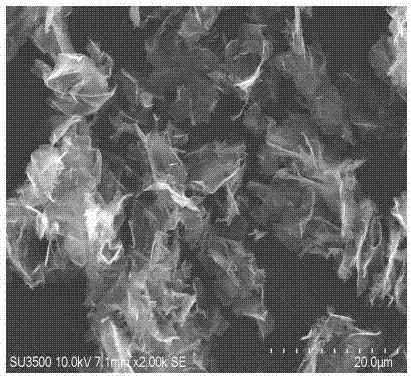

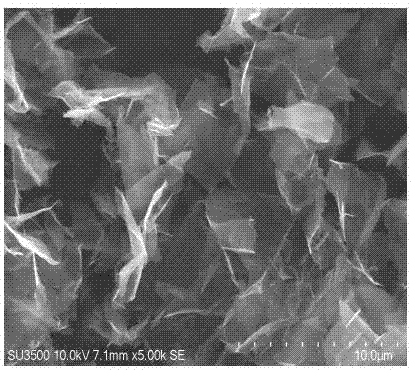

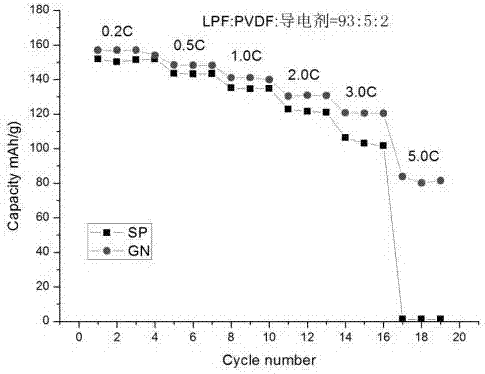

Image

Examples

Embodiment 1

[0042] A kind of preparation of graphene slurry: take by weight 94.0% deionized water and 1.0% dispersant PEO (polyethylene oxide) in dry and clean mixing tank, stir 30min until PEO dissolves completely, then add wherein Few-layer graphene 5.0%, high-speed stirring for 120min to make it evenly mixed. Then grind with a high-speed emulsifier or a colloid mill, and then use a nano-sand mill with 2.0 mm zirconia beads as the medium, and grind 5 times at 1500 rpm to obtain a uniformly dispersed graphene slurry.

Embodiment 2

[0044] A preparation of graphene slurry: take 91.0% deionized water and 2.0% dispersant PEO (polyethylene oxide) by mass parts in a dry and clean mixing tank, stir for 30min until the PEO is completely dissolved, then add Few-layer graphene 7.0%, high-speed stirring for 120min to make it evenly mixed. Then grind with a high-speed emulsifier or a colloid mill, and then use a nano-sand mill with 2.0 mm zirconia beads as the medium, and grind 5 times at 1500 rpm to obtain a uniformly dispersed graphene slurry.

Embodiment 3

[0046] A preparation of graphene slurry: take 94.0% ethylene glycol diacetate and 1.0% Vilan 108S dispersant by mass parts in a dry and clean mixing tank, stir for 10min, make it mix evenly, and then add 5.0% few-layer graphene was added therein, and stirred at a high speed for 120 minutes to make it evenly mixed. Then grind with a high-speed emulsifier or a colloid mill, and then use a nano-sand mill with 2.0 mm zirconia beads as the medium, and grind 5 times at 1500 rpm to obtain a uniformly dispersed graphene slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com